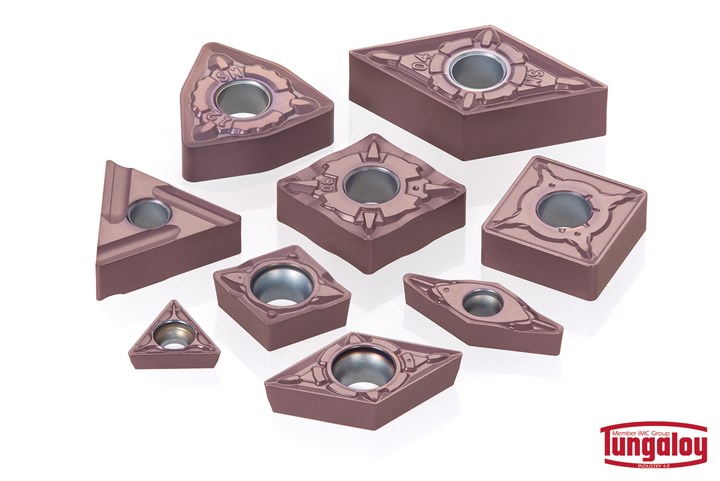

Stainless Steel Turning Grade Expands Wear Resistance Capabilities

A titanium-rich PVD coating and dedicated carbide substrate make Tungaloy’s AH6225 PVD grade insert ideal for machining ISO-M stainless steels.

Photo Credit: Tungaloy America

Tungaloy America’s AH6225 PVD grade insert for machining ISO-M stainless steels expands the application coverage from continuous to interrupted cuts in a broad range of cutting speeds, while maintaining tool life and reliability in stainless steel turning, from finishing to roughing.

A thick, titanium-rich PVD coating with high thermal stability has been developed specifically for AH62225, Tungaloy says. This coating effectively prevents crater wear from developing on the insert rake surface. The grade’s top layer incorporates a titanium-rich nano-multilayer structure; its high-density crystal orientation enhances the grade’s hardness for optimized wear resistance.

AH6225 also features a dedicated carbide substrate that reportedly excels in fracture toughness and thermal conductivity. Improved heat dissipation performance on the cutting edge prevents plastic deformation of the substrate due to thermal stress.

Related Content

-

Solving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

-

Revisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

-

6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

.png;maxWidth=300;quality=90)