Slim Line Chucks Provide Five-Axis Milling Versatility

Emuge Corp. has expanded its line of FPC milling/drilling chucks products to include slim line models that are designed to enhance five-axis machining productivity and versatility.

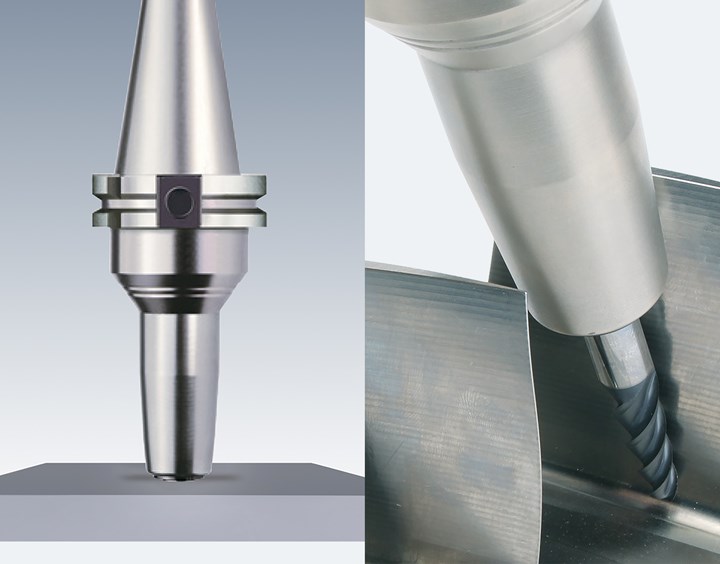

Emuge Corp. has expanded its line of FPC milling/drilling chucks products to include slim line models that are designed to enhance five-axis machining productivity and versatility. Available in the 1/8" to 9/16" (2 mm - 14 mm) size range (FPC14), the compact, slim design with tapered shape enables easier access to the work, especially in confined areas and for challenging angles.

The high precision/performance FPC mill/drill chucks provide unprecedented rigidity, vibration dampening, concentricity, machining speed, and tool life versus conventional chuck technologies for milling and drilling applications.

The chuck’s patented design delivers three tons of traction force. The unique design and body provide 100% holding power for maximum rigidity, and the collet-cone assembly absorbs virtually all vibration for maximum dampening.

Unique features and advantages include extremely high transferable torque that provides maximum process reliability; guaranteed long tool life and quality workpiece surface finishes; mechanical drive-actuated with a hex wrench; a simple design that enables quick tool changes in seconds; special holder design reduces vibration, dramatically improves workpiece surface finishes and provides exceptionally long tool life; for maximum safety, the strongest clamping force is provided to prevent the possibility of pull-out.

Emuge FPC chucks are available in five shank styles (CAT, HSK-A, SK, BT and PSC) in 68 different skus for a wide range of applications. A full range of high precision collets and accessories are also available for the FPC line. Emuge FPC Collets are available in three size ranges (FPC 14, FPC 20 and FPC 25) in over 110 different skus, from 1/8" to 1-1/4" and in metric from 2 mm - 32 mm.

Related Content

-

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

-

Laser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

-

The Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

.png;maxWidth=300;quality=90)