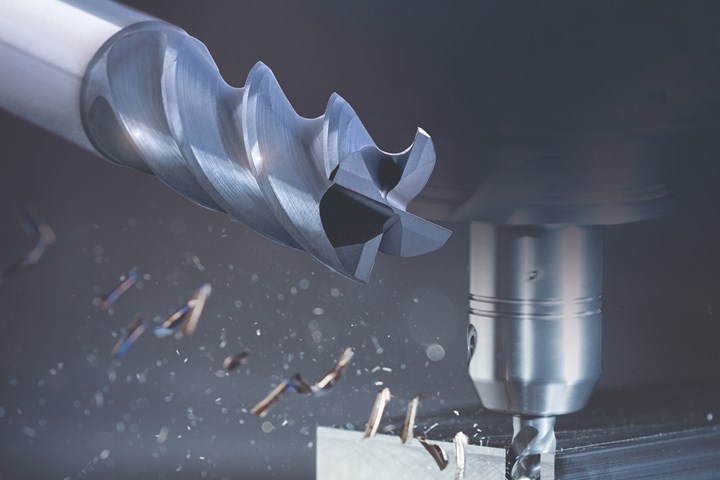

Sharp Carbide End Mills Target Reduced Cutting Forces, Tool Pressure

Made for optimum metal removing in soft, tough or high-alloyed materials commonly used in moldmaking, Guhring’s RF 100 Sharp end mills excel in unstable machining conditions and high-speed machining conditions.

Photo Credit: Guhring Inc.

For optimum metal removing in soft, tough or high-alloyed materials commonly used in moldmaking, Guhring Inc. introduces the RF 100 Sharp carbide end mill. With a rake angle of 12º, the company says the sharp milling cutter offers reduced cutting forces and tool pressure. The RF 100 Sharp excels in slotting, roughing, ramping and helical interpolation in free machining steels, stainless steels, tough special alloys and higher strength aluminum alloys.

The tough carbide substrate prevents tool breakage, and corner protection chamfers provide stability and edge strength. Long tool life is aided by optimized facet grinding for dampened vibrations, and the added protection of AlCrN coating for wear resistance.

RF 100 Sharp end mills are designed with a slightly longer cutting edge length than most standard length end mills, Guhring notes, and the long length feature both a reduced neck with extended neck length for added wall clearance in extended reach applications. RF 100 Sharp also makes milling deep into mold cavities possible.

Useful in both unstable machining conditions and high-speed machining, RF 100 Sharp end mills are available from stock in both inch and metric diameters, as well as a four-piece Sharp set.

Related Content

-

Laser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

-

Solving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

-

Treatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

.png;maxWidth=300;quality=90)