Multilayer Insert Grade Mills Difficult Mold Steels

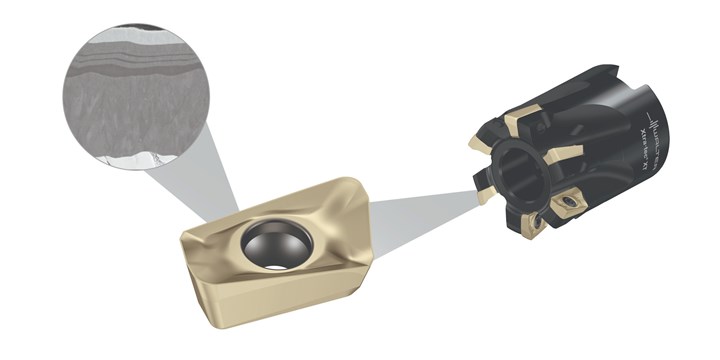

Walter USA expands its Tiger·tec Gold range with milling grade WSM35G featuring a complex, multilayered coating structure for ultimate process reliability.

Walter USA is expanding its Tiger·tec Gold cutting tool insert range with the new WSM35G milling grade. The indexable insert is coated with a PVD Al2O3 coating technology with a multilayer structure on a carbide substrate. The structure consists of a bottom TiAlN layer for high wear resistance, a middle Al2O3 layer for high temperature resistance and a ZrN gold-colored top layer for minimized friction and optimal wear detection.

The new coating ensures cutting-edge stability and therefore a long tool life, as well as high process reliability, even in complex applications, the company reports. Moreover, the WSM35G grade is for universal application including those under abrasive and difficult conditions, such as interrupted cuts or during wet machining, when milling austenitic stainless steel or nickel-based superalloys (ISO M and S workpiece groups).

The new grade is Walter’s response to the upwards trend toward milling steel with difficult machining properties and wear-resistant stainless steel. WSM35G meets stringent requirement for process reliability, which is highly valued in the automotive sector, and is also suitable for general mechanical engineering applications.

This new grade has been applied to inserts for all standard milling cutters in the Walter lineup, such as the Xtra·tec XT M5130 shoulder milling cutter, and many more.

Related Content

-

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

-

6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

-

The Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

.png;maxWidth=300;quality=90)