Machine Rebuild Service Offers Older Walter Helitronic Power Series Retrofit Option

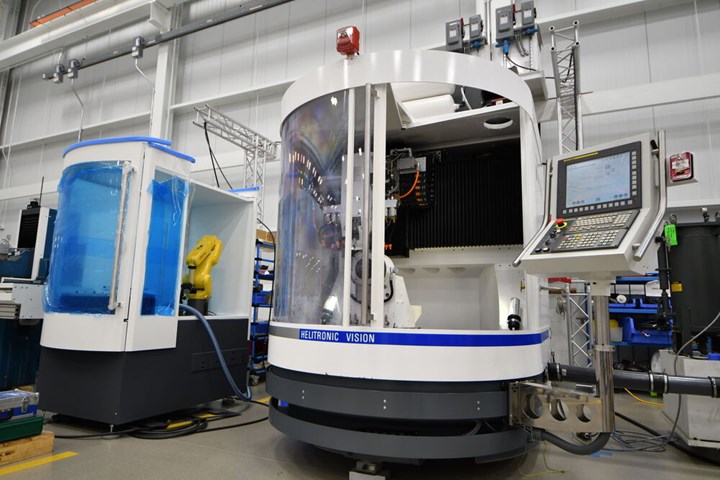

United Grinding Rebuild Department gives customers the option to replace original gantry beam-type loaders with faster, more productive FANUC LR Mate 200i robots.

Photo Credit: United Grinding

To further enhance customer benefits of its machine rebuild and remanufacture services, United Grinding North America now offers customers with older Walter Helitronic Power Series tool grinding machines the option of new advanced automation technology seamlessly retrofitted as part of a machine rebuild. The option replaces original gantry beam-type loaders with faster, more productive FANUC LR Mate 200i robots, the same as are featured on brand new Walter Helitronic machine models. In addition to cost reduction, United Grinding says a rebuild ensures recommissioned geometry, renewed guideways and enhanced precision.

In addition to speed, the new robots are said to handle an increased number of workpieces/tools, are more compact and consume less energy. They also support the latest Walter Helitronic Tool Studio and Robot Manager software that enables users to load multiple trays with various workpiece diameters for lights-out unattended production.

To allow for retrofitting modern automation when rebuilding the machines, Walter reengineered and reconfigured its controls. Now, as part of a rebuild, United Grinding outfits machines with the new FANUC CNC as well as all new electrics (FANUC drives and motors) that accommodate the robots and all necessary software.

United Grinding says the FANUC CNC extends machine lifespan as well as adds features, functions and convenience. User-friendly conversational programming and advanced functions are also available.

Related Content

-

Predictive Manufacturing Moves Mold Builder into Advanced Medical Component Manufacturing

From a hot rod hobby, medical molds and shop performance to technology extremes, key relationships and a growth strategy, it’s obvious details matter at Eden Tool.

-

Developments in High-Speed Machining Technology

There have been many exciting developments in high-speed machining relative to machining centers and controls, tooling and CAD/CAM systems.

-

3D Printing Enables Better Coolant Delivery in Milling Operations

Just like 3D printing enabled conformal cooling channels in molds, additive manufacturing is now being used to optimize coolant delivery in cutting tools.

.jpg;maxWidth=300;quality=90)