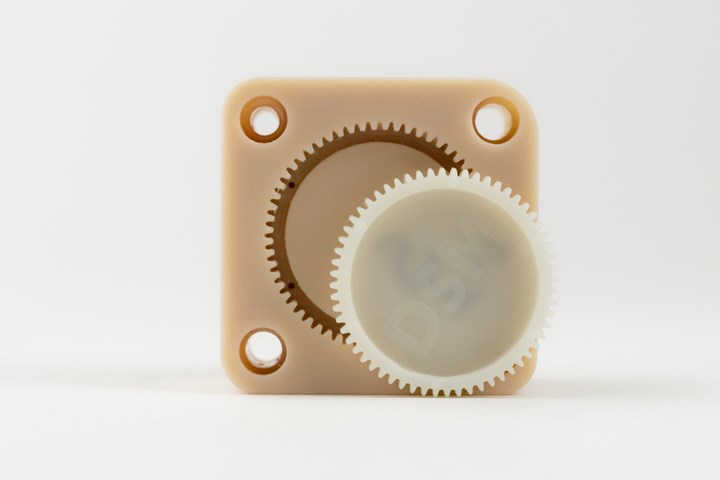

Industrial 3D Printing Solution Proves Rapid Injection Mold Tooling Production Capacity

Covestro DLP resin e-PerFORM used with EnvisionTEC’s Perfactory P4K series DLP 3D printing demonstrates faster, more cost-effective print speeds with high stiffness, high temperature performance.

Photo Credit: Covestro, EnvisionTEC

EnvisionTEC (Dearborn, Mich., U.S.), a wholly owned subsidiary of Desktop Metal, and polymer company Covestro AG (Leverkusen, Germany) have combined Covestro’s new DLP resin e-PerFORM and EnvisionTEC’s Perfactory P4K series printer technology for a complete industrial manufacturing solution for rapid, cost-effective 3D printing of injection mold tooling.

EnvisionTEC says it tested the e-PerFORM resin with key molding institutes to validate the material’s performance. Completed mold trials demonstrate that e-PerFORM resin, with high stiffness and high temperature performance, behaves similarly to stereolithography resin Somos PerFORM for injection molding tooling.

Further tests performed by Polyvia, the French Federation of Plastics and Composites, are said to have confirmed the suitability for rapid tooling, including good results in part fidelity and in the number of shots molded in both polypropylene and glass-reinforced nylon.

Related Content

-

Precision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

-

Large Hybrid Steel Insert Solves Deformation, Dimensionality, Cycle Time Problems

DMLS printers using metal additive powders selected by Linear AMS to produce high-quality, accurate, consistent 3D-printed mold components with certification and traceability.

-

MMT Chats: The Connection Between Additive Manufacturing Education and ROI

This MMT Chat continues the conversation with Action Mold and Machining, as two members of the Additive Manufacturing team dig a little deeper into AM education, AM’s return on investment and the facility and equipment requirements to implement AM properly.

.jpg;maxWidth=300;quality=90)