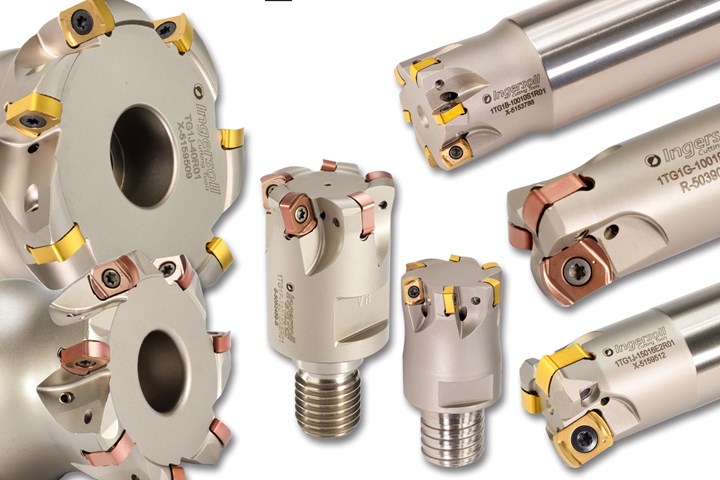

Indexable High-Feed Mills Family is Expanded and Enhanced

The Ingersoll DiPosFeed series features four insert sizes, grades for all materials, three different cutting-edge preparation options and a range of cutter diameters.

Photo Credit: Ingersoll Cutting Tools

The DiPosFeed series of indexable high-feed mills by Ingersoll Cutting Tools are said to offer extreme milling performance. Key features include four insert sizes, grades for all materials, three different cutting-edge preparation options, strong radius high-feed insert geometry and fine and coarse pitch cutter capabilities. The 4-, 6-, 9- and 11-mm inserts offer depth of cut ranges of 0.5, 1, 1.5 and 2 mm, respectively.

A wide range of cutter diameters is available in both inch and metric sizes. Cutter body types include face mill, end mill and modular connection types. Higher density cutter options and lower cutting forces provide higher feed rates, increased material removal rates and substantial productivity increases. Robust cutting edges and rigid clamping offer cutter stability and reliability.

Related Content

-

Maintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

-

Revisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

-

Advantages and Disadvantages of Copper and Graphite Electrodes

Both copper and graphite provide approximately the same end result, so it is important for a shop to consider the advantages and disadvantages of each material in order to discover what would work best in their shop floor environment.

.png;maxWidth=300;quality=90)