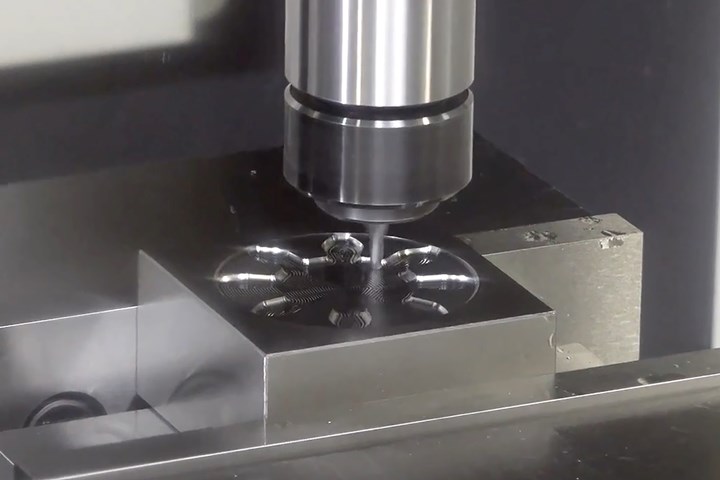

Corner Radius End Mill Series Meets Challenge of Milling Alloys Over 60 HRC

Union Tool’s four-flute, long neck radius end mill series, HGLRS 4000, offers an enhanced carbide material, HMG coating and altered geometries.

Photo Credit: Union Tool

Over the last few years, Union Tool says, the demand for extended life of molds and dies has led to the supply of new technologies that meets the machining needs of cutting high hardness and/or abrasive alloys with accuracy, extended tool life and cost-efficient programs.

Over a year ago Union Tool launched the HGB/HGLB ball nose series, which is said to have met these goals. More recently, the company release a four-flute, long neck radius end mill series, HGLRS 4000, for a corner radius option.

Like HGB/HGLB, Union Tool’s enhanced carbide material, HMG coating and altered geometries enable HGLRS 4000 to meet the challenges of milling alloys over 60 HRC. The carbide material and coating work to reduce tool wear along with new rake angle geometries that hold up to the heat and necessary cutting force.

According to Union Tool, case studies have found when using the HGLRS series for finishing, surface roughness (Ra) became smoother, and wall accuracy (Rz) in vertical direction improved

The initial launch offers 72 models in diameters ranging from Φ1 to φ6, with various corner radius and length options.

Related Content

-

Fundamentals of Designing the Optimal Cooling System

The right mold components can help improve mold cooling and thereby produce higher-quality parts.

-

Maintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

-

Laser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

.png;maxWidth=300;quality=90)