Up Close with Engel LSR Technology

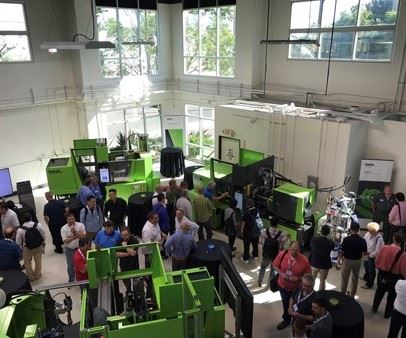

Engel’s Open House, run in conjunction with the LSR 2018 Conference in Anaheim, CA brought over 100 guests up close to the latest in LSR molding technology.

Share

Over 100 visitors were welcomed to Engel North America for an Open House at the Engel West facility in Corona, California. The Open House, held on September 13th, was held in conjunction with the LSR 2018 conference in Anaheim, California and offered attendees the opportunity to examine the latest in LSR molding technology.

A selection of liquid silicone injection molding applications were presented in the Technical Center of Engel West, giving the conference attendees a view of these processes:

- A tie-bar-less Victory 200/55 US machine, equipped with an integrated Engel Viper6 robot, produced eyeglass lenses using optical grade LSR.

- A 4-cavity radial seal mold from ACH ran, with a cycle time of 20 seconds, on an all-electric Engel E-Mac 170/55 US machine. For this event, the machine was outfitted with an optional LSR package.

- An all-electric Wintec E-Win 1000-310 machine (with 1,000 kN clamping force), equipped with an Engel Viper linear robot, ran a two-cavity mold supplied by Roembke Manufacturing molding specimen containers for medical diagnostics.

Related Content

-

Making Mentoring Work | MMT Chat Part 2

Three of the TK Mold and Engineering team in Romeo, Michigan join me for Part 2 of this MMT Chat on mentorship by sharing how the AMBA’s Meet a Mentor Program works, lessons learned (and applied) and the way your shop can join this effort.

-

OEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

-

Editorial Guidelines: Editorial Advisory Board

The Editorial Advisory Board of MoldMaking Technology is made up of authorities with expertise within their respective business, industry, technology and profession. Their role is to advise on timely issues, trends, advances in the field, offer editorial thought and direction, review and comment on specific articles and generally act as a sounding board and a conscience for the publication.