Joint Research Project 3D Prints MIM Tool With Near-Contour Cooling

The University of Rostock and Stenzel MIM Technik GmbH has created a process approach that can produce a 3D-printed metal injection mold in about five days, versus eight weeks.

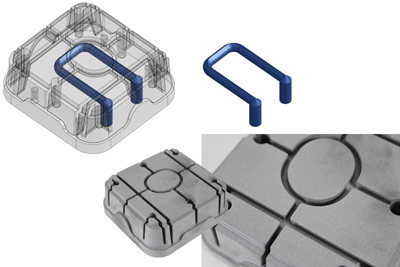

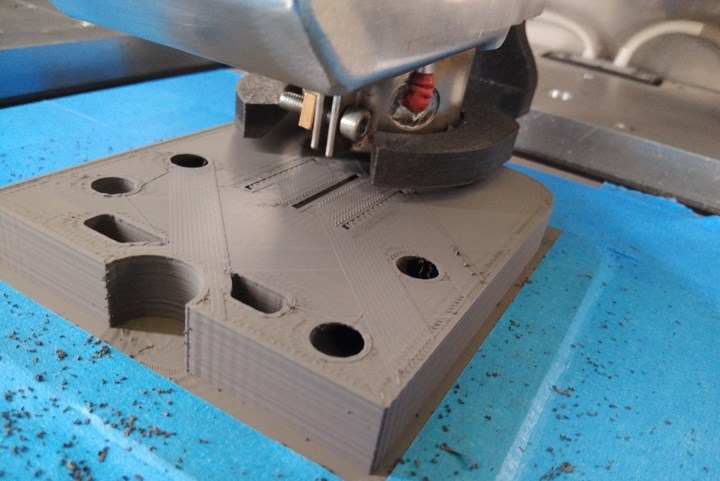

A 3D-printed tool for metal injection molding being produced on an ExAM 255. Photo Credit, all images: AIM3D GmbH, Rockstock (Germany)

The Chair of Microfluidics (LFM) at the University of Rostock in Germany is working together with Stenzel MIM Technik GmbH on a project to print a 3D metal injection molding (MIM) tool, with the goal of developing a new process chain for the cost-efficient and rapid production of MIM tools. The basis of the development is the use of spin-off company AIM3D’s composite extrusion modeling (CEM) technology with an ExAM 255 system. The multi-material ExAM 255 3D printing system enables high build speeds for high-precision 3D components manufacture. Compared to a conventional approach in machining, the use of an additive manufacturing (AM) process to produce a MIM tool reduced the total production time from around eight weeks to approximately five days.

The goal of this joint project was to use 3D printing to manufacture a tool for MIM with near-contour cooling. In 3D printing, near-contour cooling can be incorporated as a so-called functional integration with helical channels directly in the tool. In other words, it is not embedded as inlets, as is the case with larger tools.

The goal of any near-contour cooling of injection molds made out of metals or polymers is to significantly reduce the cycle time. The principle of near-contour cooling is to guide coolant fluids through near-contour cooling channels with low cross-sections, enabling component cooling during the cycle. This leads to a faster demolding process. The complex geometry of the helical cooling channels is created with the help of CAD technology using simulation models that are based on the “needs” of the component. Long-term experience shows a reduction in cycle time by around 20%, depending on wall thickness and size.

As an integrated component solution, 3D printing offers the advantage of a “one-shot technique” as a functional integration compared to mold-bound processes. The application example therefore demonstrates an opportunity to drastically reduce the time-to-market.

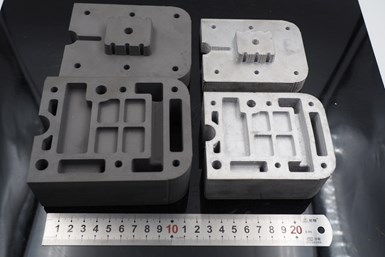

For the project, an optimized 3D model of the tool was initially developed using CAD and simulation tools. This data was then transferred to the ExAM 255 CEM system, together with the necessary process parameters. A so-called “green part” is then 3D printed. Afterward, the part is sintered in a multistage process to produce the final material properties.

According to project partners, with this process, complex metallic components can be rapidly produced after the necessary debinding and sintering steps. At the same time, the CEM process allows for the control of the volumetric shrinkage associated with sintering. The resulting mold has a cavity. The component consists of a thick-walled part with thin fins. These fins cannot be produced without near-contour cooling, as they are difficult to demold. Stenzel MIM Technik hopes to achieve a significant reduction in cycle time for this component by up to 70-80%. However, injection molding trials for testing are still pending.

Will this 3D approach change the future of toolmaking? According to Dr. Abdullah Riaz, research associate at the Chair of Microfluidics at the University of Rostock, “This depends on the dimensions of such a tool. With smaller molds, the charm lies in fast build rates. This results in an economic limit for larger molds, which is defined by the respective state-of-the-art of the system technology. With increasing build rates, this limit can be shifted upwards. In the future, functional integration, such as near-contour cooling and the ‘one-shot’ strategy for reducing the number of components with a 3D printing process, will be interesting. Among other things, this can eliminate the need for assembly and simplify the component.”

The project, funded by the German Federal Ministry for Economic Affairs and Energy (BMWi) is taking place from April 2021 to October 2023.

Related Content

Products and Services for Multiple Moldmaking Needs

New year, new technology roundup! Featured here is a collection of product offerings, from profile milling cutters to industry-specific CAD/CAM software to innovative hot work tool steels.

Read MoreHow Hybrid Tooling Accelerates Product Development, Sustainability for PepsiCo

The consumer products giant used to wait weeks and spend thousands on each iteration of a prototype blow mold. Now, new blow molds are available in days and cost just a few hundred dollars.

Read MoreIn "Hybrid" FIM Process, 3D Printing Complements Injection Molding

Alpine Advanced Materials used a desktop 3D printer and the freeform injection molding process to reduce prototype tooling production time and cost for its customers.

Read More3D Printing Innovates Hot Runner Manifold Design

Metal 3D printing combined with a conventionally machined manifold block overcomes flow shadows on valve gates and offers faster color changes while providing closer system pitch centerlines between cavities.

Read MoreRead Next

A European View on AM: Rethinking Injection Molds

Overseas business models and applications of metal additive manufacturing promise to improve or invent functionalities integrated into molds and tools.

Read MoreMetal AM Advances in Composite Tooling

Multiple metal additive technologies are gaining market acceptance and interest for composite tooling used in processes ranging from short-fiber injection to autoclave-cure prepreg.

Read MoreMantle to Deliver Production Metal 3D Printers for Moldmakers, Molders

Demonstration of continued market momentum is seen by delivery of the P-200 printer to Westec Plastics and Westminster Tool’s success with a Mantle beta system. Mantle will be featuring these achievements at this week’s MoldMaking Conference.

Read More

.JPG;maxWidth=150;quality=70)

.jpg;maxWidth=300;quality=90)

.JPG;maxWidth=400;quality=70)