Geomagic Announces Geomagic Spark, a Revolutionary New Approach to Designing from Scan Data

At EuroMold in Frankfurt Germany last week, Geomagic®, a global company providing 3D technology for digital reality, announced Geomagic® Spark™, the newest addition to the company’s line of powerful 3D scan, design and inspection applications.

At EuroMold in Frankfurt Germany last week, Geomagic®, a global company providing 3D technology for digital reality, announced Geomagic® Spark™, the newest addition to the company’s line of powerful 3D scan, design and inspection applications.

Geomagic Spark is the result of a collaboration between Geomagic and a leader in 3D direct modeling, SpaceClaim. The companies’ close partnership began when Geomagic introduced its initial SpaceClaim integration in the 2012 release of Geomagic Studio®. After a successful launch and positive user feedback, both realized that a fully integrated application would change the landscape of designing from 3D scans. This resulted in the creation of a new application: Geomagic Spark.

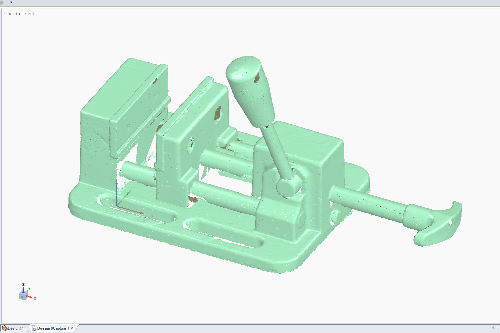

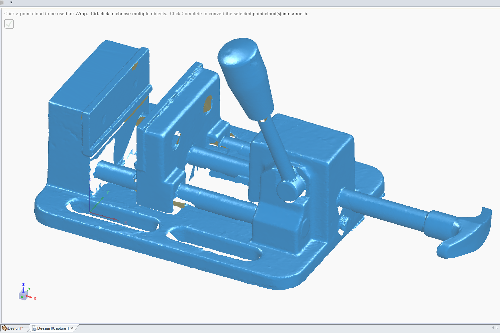

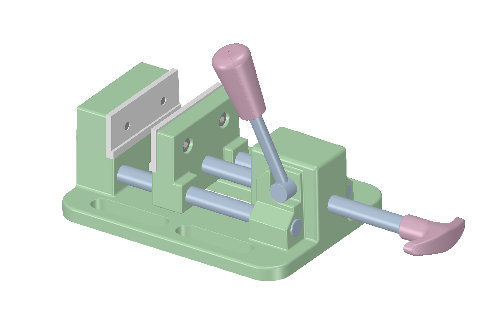

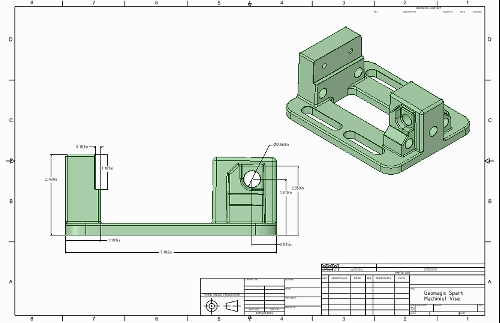

Geomagic Spark combines a live 3D scanning interface, robust 3D point and mesh editing capabilities, comprehensive modeling design, assembly modeling, and 2D drawing creation in one complete application.

Geomagic Spark incorporates 3D scan data functionality, integrating Geomagic’s advanced scanning technology, 15 years in the making, with the robust, easy-to-use direct modeling capabilities of the SpaceClaim® platform. Now, users can create accurate, manufacturable solid models and assemblies using combined scan and CAD data in the same application within minutes, even with partial scan data.

Geomagic Spark is ideal for engineers and manufacturers that design in 3D from existing objects or those that need to finish or modify scanned parts. With the power of Geomagic Spark, companies in the automotive, electronics, industrial design, consumer goods, tooling and aerospace industries can facilitate better communication between engineering teams, simplify design processes, and increase reliability in scan-to-CAD operations.

The innovation of Geomagic Spark has already caught the attention and imaginations of major scanner manufacturers such as Creaform®.

“We at Creaform think that this is a move in the right direction. It’s perfectly in line with our commitment to help designers continuously accelerate their development cycles,” says Creaform’s Vice President of Innovation and Technologies, Marco St-Pierre. “Creaform is accomplishing this mission through the development of truly portable, user-friendly, accurate 3D measurement devices. Now Geomagic is doing it with its new Geomagic Spark.”

Description and Features: Geomagic Spark’s integrated package includes point cloud, mesh and CAD modeling in the same user interface. Designers can simply scan directly into Geomagic Spark or load an existing point cloud or polygon mesh. From there they can choose from the wide range of automated tools used to convert and edit data into a polygon mesh: sampling, noise reduction, wrap, mesh simplification and more. Geomagic Spark’s intuitive solid modeling tools simplify the process of creating solid geometry from the mesh, allowing one-button extraction of curves, surfaces and solids. Once the solid model is created, users can then compare the solid model to the mesh upon which it is based, identifying areas of deviation. 2D technical drawings, annotations, dimensions and more are available instantaneously and can be created interactively with the 3D data. Export to CAD-neutral formats is fast and simple as well. This powerful combination of 3D data processing and CAD functionality catalyzes process efficiency in reverse engineering, production-focused manufacturing, prototyping, concept modeling and creation, documentation and service bureau production.

Geomagic Spark makes scanning and designing in 3D a more straightforward process. Via SpaceClaim’s smart and predictive user interface, users can intuitively interact with models and forgo the intricacies and limitations of a complex, multi-level feature tree. This tremendous ease-of-use makes Geomagic Spark’s tools accessible to everyone, thus allowing organizations to close the gap between engineering and design while including data from real-world objects.

In creating this dynamic, easy-to-use new tool, Geomagic’s development team included a number of sophisticated features in Geomagic Spark:

• Direct scanning into Geomagic Spark using hardware plug-ins for Faro®, Hexagon® and Creaform (others to be announced)

• Point cloud editing – Deletion, sampling, noise reduction, etc.

• Native CAD format import via add-ins from SpaceClaim

• Mesh editing – Deletion, hole filling, trim and repair

• Intelligent selection tools

• Accurate extraction of surfaces, solids and sketches from the mesh

• Intuitive push/pull geometry modification tools

• Complete sketching and solid modeling capability

• Mesh-to-solid deviation analysis

• 2D drawing creation

• 3D PDF generation

• Assembly creation, manipulation and editing

• Compatible with a powerful collection of third-party add-ins for SpaceClaim (e.g., photorealistic visualization, PDM, analysis and CAM)

• Interoperable with a range of CAD and PLM tools in addition to neutral file formats (IGES, STEP, OBJ, ACIS, PDF and more)

Availability: Geomagic Spark will be available at the end of January 2013. After its release in January 2013, free trials of Geomagic Spark will be available at www.geomagic.com.

Geomagic Spark will also be available as part of Geomagic’s new Enterprise Bundle, which will also include Geomagic Studio and Geomagic Qualify®. The Enterprise Bundle offers significant savings for those who require a full suite of 3D scan-to-CAD capabilities, advanced point and mesh processing, and cutting-edge metrology applications to leverage their 3D scanners.

Related Content

Shift in U.S. Mold Imports: Emerging Countries Gain Ground in Market Share

The dynamic nature of the U.S. mold industry's global trade landscape offers challenges and opportunities for growth.

Read MoreDynamic Tool Corp: Leadtime Leader Insights and Bold Plans for the Future | MMT Chats

MoldMaking Technology Editorial Director Christina Fuges gets the scoop from our 2024 Leadtime Leader Award Winner Dynamic Tool Corp., on the company's future, their trade show experience, finding new talent and the impact of this industry recognition.

Read MoreThe Critical Role of Management Representatives in ISO 9001

In ISO 9001 quality management systems, the Management Representative (MR) plays a crucial role. While the 2015 version of ISO 9001 no longer mandates this position, having a trusted management member serve as an MR remains vital for streamlining operations and maintaining quality standards.

Read MoreMoldMaking Conference Session Spotlight: Data

Want to learn about digital workflows in mold design or ERP or global mold monitoring and asset management or the impact of tooling digitalization?

Read MoreRead Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More