FANUC, Rockwell Automation Form Coalition to Close the Manufacturing Skills Gaps

Offered apprenticeship programs in advanced manufacturing, automation and robotics aim to help companies rapidly upskill current and future workers.

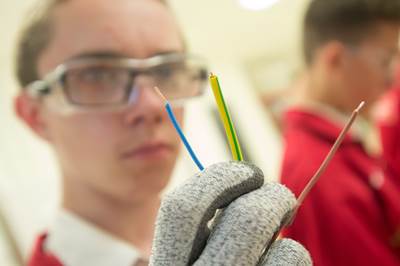

Photo Credit: FANUC America

It was reported on Feb. 23 that FANUC America (Rochester Hills, Michigan) and Rockwell Automation (Milwaukee, Wisconsin) have officially formed a coalition to kick off accelerated work-and-learn apprenticeship programs designed to upskill current and future workers for jobs in advanced manufacturing, robotics and automation.

The coalition includes APT Manufacturing (Hicksville, Ohio), a FANUC and Rockwell Automation systems integrator, and NOCTI Business Solutions (NBS), which provides independent assessments of occupational standards and validation using recognized International Organization for Standardization (ISO) process validation methods. Franklin Apprenticeships (Sparks, Maryland) is also a key partner of the coalition, ensuring apprenticeship support structure and success enablers for employers and apprentices.

“As technology advances at a fast pace, it is important that companies play a bigger role in education to ensure a safe, productive and sustainable work environment.”

“As industry adopts new technologies, it is vital to be able to quickly adapt with a well-trained workforce,” says Michael Cook, director Global Academic Organization, Rockwell Automation. “Having the most current standards will drive manufacturing competitiveness and simultaneously grow new talent to these new occupations, upskill current employees, and allow companies to be more agile in their workforce planning.”

The coalition has reportedly developed new apprenticeship programs offering people opportunities to gain credentials that include fundamental robotics (Robot Operator) and automation (PLC Operator). The program offers a second level of credentials for Robot and PLC Technicians. A third credentialing level called Integration Specialist builds on the fundamental and technical skills that teaches people to operate and troubleshoot integrated FANUC-Rockwell Automation technologies. According to the coalition, all of the new apprenticeship offerings will provide more people with fulfilling careers and help companies to bridge the demand for skilled workers.

“Our number one goal is to help create a worker pipeline that will not only help people increase their skills and future earning potential, but to help manufacturers achieve their production goals and maintain a thriving economy,” says Paul Aiello, director of Education, FANUC America. “In most cases, current and future workers can complete the apprenticeship skills training and achieve their industry-recognized certifications in less than one year. It’s also important to note that these programs support all types of apprenticeship and certification models, including pre-apprenticeships.”

The apprenticeship programs aim to help companies rapidly upskill employees at every level from Operator to Technician to Integration System Specialist. In addition to improving the skills of current production workers, the coalition notes that these programs will be extremely valuable for engineers who are working to implement new automation systems and processes that require new employees trained in the latest automation technologies.

“As technology advances at a fast pace, it is important that companies play a bigger role in education to ensure a safe, productive and sustainable work environment,” adds Aiello. “FANUC and our coalition look forward to helping as many people as possible take advantage of these accelerated work and apprenticeship programs.”

More than 40 leading companies, including Dana, Magna, Tyson Foods and Flex-N-Gate, have agreed to support and participate in apprenticeships for automation technologies, ensuring that their employees receive adequate training and are qualified to succeed.

FANUC and Rockwell Automation have worked together over the past decade developing training, certifications and an education and training delivery network. FANUC’s network of educational partners includes more than 1,200 high school and post-secondary FANUC-certified training organizations, and more than 150 university and career technical training partners associated with this industry team. FANUC’s network of schools coupled with Rockwell Automation’s education partners represent nearly 1,600 schools, said to be the largest nationwide collaboration of industry and education working to narrow the skills gap. For more information, visit here.

Related Content

Machining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreSolving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

Read MoreLaser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreRead Next

MMT On-Demand IMTS Spark Sessions: Mentorship and Apprenticeship

Just because you missed the live stream of MoldMaking Technology's first two sessions on IMTS Spark, doesn’t mean you need to miss out completely because both sessions are now available for viewing on-demand.

Read MoreNIMS, Edge Factor Provide Free Educational Experience for Next-Generation Workforce

Online Experiences empower students, parents and job-seekers to explore skilled trades, apprenticeships, hands-on learning programs, careers, STEAM and soft skills in advanced manufacturing.

Read MoreAdi Group Encourages Pre-Apprenticeship Program for Next-Generation

In a pandemic-stricken climate, a pre-apprenticeship approach may offer up a practical learning path to those young people whose formal education has been disrupted.

Read More

.jpg;maxWidth=300;quality=90)