Dry Ice Is Essential for COVID-19 Vaccine Distribution

A leader in the manufacturing of dry ice production and blasting equipment and is currently helping industry and governments to safely distribute billions of COVID-19 vaccine doses around the world.

Based on current projections, up to 50 million COVID-19 vaccine doses will be distributed globally in 2020 and up to 1.3 billion doses by the end of 2021. Some vaccines in development must maintain a consistent temperature of approximately −109.3 °F (-78.5 °C) during storage and shipment to remain stable and viable, which presents a logistical challenge in the global distribution. This is where Cold Jet® is making a difference with its dry ice production and equipment.

“Dosing dry ice directly into temperature-controlled thermal shippers is the only way to maintain that temperature level during transit and storage.”

Pharmaceutical and logistics companies as well as governmental agencies need to create an ultra-low temperature cold chain in order to keep vaccines below sub-zero temperatures. Currently, the existing refrigerated transport infrastructure and supply chain is not prepared to handle these types of shipments. Dry ice, made of recycled CO2, will be essential in the safe distribution of every single one of these doses. It sublimates without creating any waste or residue, making it the perfect refrigerating medium during the shipment of vaccines.

“Dosing dry ice directly into temperature-controlled thermal shippers is the only way to maintain that temperature level during transit and storage,” said Wim Eeckelaers, Managing Director, EMEA, Cold Jet. “At all points in the vaccine transportation and distribution cold chain, dry ice is needed to maintain temperature.”

Dry ice has long been an essential contributor to the global economy. However, it has taken on a new responsibility in humanity’s fight against COVID-19. Once dry ice reaches local communities, it will be further divided up and sent to vaccination centers, public and mobile clinics, hospitals, and pharmacies. Cold Jet is working with local distributors around the world to ensure that they are able to meet the needs of all communities, whether they are in the inner-city or in hard to reach rural areas.

The World Health Organization cites inadequate cold chain capacity as a major issue to vaccine distribution in developing economies. In recent years, millions of doses of vaccines were lost due to cold chain failures. Cold Jet’s Dry Ice Production Hub helps solve this issue. “We want to guarantee that any person, no matter where they live in the world, is able to obtain a safe and viable vaccine,” said Dennis Hjort, Vice President – Global Dry Ice Manufacturing Systems, Cold Jet.

Cold Jet’s dry ice production machines are capable of producing up to 1,600 pounds (750 kilograms) per hour and are engineered to run 24 hours a day, seven days a week. From the packaging lines at a multinational pharmaceutical company to distribution centers at global logistics companies and locally within hundreds of communities around the world, Cold Jet machines are producing dry ice at all points in the vaccine distribution cold chain.

“The impact of COVID-19 on global health and the global economy has been painful, but Cold Jet is extremely proud to play such a vital part in the distribution process of a vaccine,” said Eeckelaers.

Related Content

Think Safety: Eliminate Hazards Throughout the Shop

The tooling community is taking advantage of new products for safer mold shops and molding facilities.

Read MoreWhat You Need to Know About Hot Runner Systems and How to Optimize Their Performance

How to make the most out of the hot runner design, function and performance.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreHow to Overcome Complex Mold Texturing Problems

Key benefits when considering laser technology for mold texturing and repair.

Read MoreRead Next

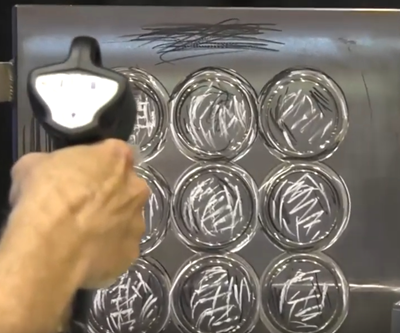

Dry Ice Provides Optimum Range of Possibilities in Parts Cleaning Process

Cold Jet LLC showcases how they use dry ice (solid CO2) in their parts cleaning process.

Read MorePODCAST: Educators in Mold Maintenance

The key to successfully educating mold builders and molders about mold maintenance is to listen twice as much as you talk for the improvement in finding problems and creating solutions.

Read MoreMold Cleaning Case in Point

The cold hard facts about dry ice cleaning and a system that helps reduce cleaning time and machine downtime by 95 percent while improving process security.

Read More.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)