Due to rising material costs and the inability to use regrind, the benefits of direct gating with runnerless molding have become more compelling. For molders considering a transition to this niche market, LSR can be a challenging manufacturing process and learning experience due to the material's viscosity characteristics and unique chemistry. Where thermoplastic injection molding accomplishes runnerless molding with a hot runner, LSR injection molders accomplish the same goal with a cold deck.

Agenda:

- The requirements and concepts of LSR injection molding

- How LSR injection molding differs from traditional thermoplastic injection molding

- The benefits of runnerless molding and reducing waste with cold deck technology

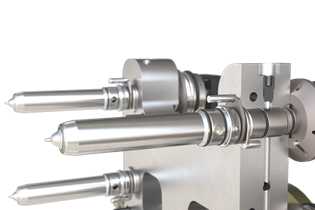

- Key considerations and unique features required by cold deck design for successful runnerless molding

.jpg;maxWidth=300;quality=90)