The Business Side of Moldmaking

This shop’s experience shows that skilled people and the most sophisticated machinery go only so far.

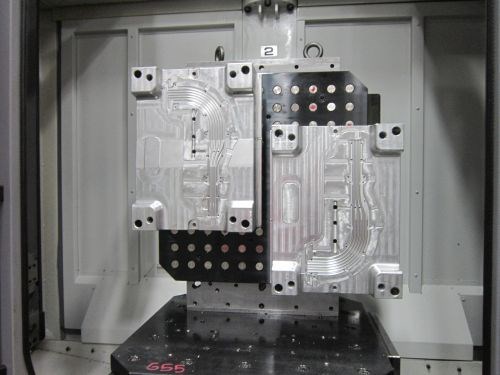

The picture above, taken at Roseville, Michigan-based Midwest Mold Services, depicts multiple blocks mounted on an FCS Fixture Plate from Single Source Technologies. This setup was performed on one pallet while a different job on a second pallet underwent machining in the workzone of the shop’s HM 600 HMC from OKK USA Corp. Precise repeatable setups that eliminate the need to reindicate, the pallet changer, and the fact that a horizontal machine can access multiple sides of the workpiece all help keep costs low at this 37,000-square-foot plant. Yet, president and CEO John Hill emphasizes that even the most sophisticated technology can go only so far to ensuring competitiveness.

Now, you’re probably expecting to read something along the lines of how what’s really important isn’t the technology itself, but how it’s used. However, that’s not enough either, Hill says. Mold manufacturing is a business, and he attributes much of Midwest’s success to the fact that he and the rest of the shop’s leadership haven’t lost sight of that fact. Read this profile to learn more.