How to Use Hydraulic Locking Cylinders to Improve Plastic Injection-Molded Part Profitability

Improve complex injection-molded part quality and profitability by reducing mold base size and preloading slides from a solid structure to ensure placement.

Profitability impacts everyone in the mold supply chain because the mold builder, molder and OEM must consider both mold cost and cost per part, which is highly dependent on mold complexity. The challenge is finding the most creative solution to meet requirements at the lowest overall cost for the mold builder, molder and OEM. Hydraulic locking cylinders can provide a solution.

Mold builders can easily produce right-sized simple molds because part size fundamentally defines mold size. Complex molds, however, often push the limits of design creativity with demanding part quality and larger side-action footprints. Higher quality demands better-performing fits to maintain part dimensionality, and complexity often makes action design more expansive for relatively small parts. When you increase both mold and machine size, you get higher mold costs, slower process speeds and higher costs per part.

Driving profitability in the right direction requires driving the mold base size back down to lower costs and preloading slides for optimal part quality.

Smaller mold bases and improved structural integrity equal increased value add at lower costs.

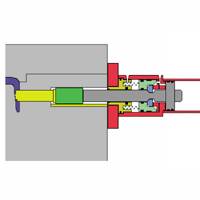

Complex mold designs in smaller mold bases. A designer can easily solve the mold base problem by moving the majority of the side action to the outside of the mold base with standard NFPA-style or compact hydraulic cylinders that mount to the mold base externally, but capturing slides takes room inside the mold base. Hydraulic preloading and locking cylinders mount fully external to the mold base and provide independent control to keep the mold base smaller, without the drawbacks of compact or standard cylinders. Locking cylinders can also be “quick mounted” to allow installation after setting the mold to fit into the smallest machines and accommodate long core strokes.

Complex interfaces with better part quality. Timing complex actions is challenging particularly those with multiple core shutoffs, due to core overtravel, sequencing and simultaneous insertion. A better option is to preload cores into position on a hard stop using hydraulic locking side-actions. This method ensures zero movement of slide faces during placement and injection, while moving the mounting support locations away from the part to the more rigid outer mold base structure, enhancing the integrity of the mold cavity structure and fit.

Competitive advantages for the supply chain. An optimized mold can be placed in a smaller press that inherently runs faster, and a mold that performs better with a smaller footprint can command premium prices, yielding a lower cost to manufacture — a win for the entire supply chain.

For example, a mold that costs the builder less, but also runs at a lower cost per part in a smaller machine with improved part quality, justifies a higher performance-based price, benefiting the mold builder. Higher quality parts produced from a high-performance mold at competitive pricing supports lean manufacturing initiatives, increasing the molder’s value as a supplier to the OEM customer. The optimized mold then eliminates waste and produces the most efficient cost structure and thus, more profitability.

About the Contributor

Mark Scanlan is vice president of PFA, Inc.

262-250-4410 / mscanlan@pfa-inc.com / pfa-inc.com

Related Content

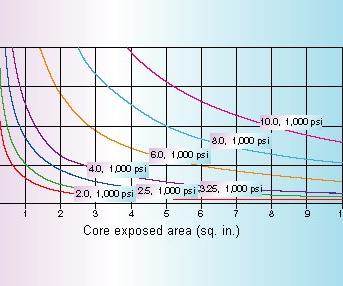

How to Correctly Size a Hydraulic Cylinder

This week Randy shares steps for correctly sizing a hydraulic cylinder on a mold.

Read MoreMold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

Read MoreMaintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

Read MoreRevisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

Read MoreRead Next

Mold Side-Actions: How, Why and When They Work

Understanding the effects of injection on the core, slide and associated components is critical to selecting the best side-action methods for a given application. This first of two articles will discuss the basic physics underlying all side-actions.

Read MoreMold Side-Actions: Applications Rule the Action

With a firm understanding of the effects of injection on the core, slide and associated components, this second of two articles will discuss emerging modular technologies which provide alternatives to the limited solutions previously available.

Read MoreModular Side-Action System in Medical Part Molding Reduces Downtime, Cycle Times

Case Study/Mold Components, Medical.

Read More

.jpg;maxWidth=300;quality=90)