Working On My Business: Leadership Style Sets Tone for Shop Performance

What is your style of management? How do you manage conflict? The answers to these questions could determine how your business thrives or struggles in the new year.

Over the last two years speed and nimbleness have been discussed as key strategic drivers for maintaining competitiveness in the global market - the market where mass customization is becoming the standard. Shorter lead times, smaller quantities per order, smaller batches and just-in-time everything comprises the world of today's manufacturer.

Speed is usually equated with time-to-market issues for product developers and leadtimes for shops. Nimbleness, on the other hand, is a measure of a company's ability to manage change - to turn on a dime and give customers what they want, when they want it and how they want it. These two factors are the baseline metrics for determining competitive differentiation, fiscal fitness and even survival for many shops.

Automation and technology can bring some relief in the quest for mastering these two elusive core competencies. Moldmakers have a tendency to focus on the machines, tools for design and engineering and unique technologies. Each offers a form of benefit as well as a potential bottleneck, but they are topics to cover in a different article.

The real driver in most shop environments is human capital - the people connection. Experience with companies all over the world has verified what George Stalk and Thomas Hout, co-authors of Competing Against Time, found in the late eighties: Speed in an organization is handicapped throughout an organization. Specifically, the bottlenecks occur in equal measure at: (1) The front-end - planning, sales, order processing, office operations, design and engineering; (2) The middle - typically manufacturing, operations management and supply channels; and (3) The back-end part of the business - packaging, packing, distribution, transportation and collection. The source of the handicap is primarily decision-making, scheduling-related issues including priorities and rework. Stalk and Hout called this the "3/3 Rule." Today, we still see these same issues repeated over and over again in industry.

When taking a closer look at the source of the problem, you can find a common denominator: leadership. Whether it's for innovation or normal daily shop operations, the issues are the same. Having the right machines, processes and engineering design tools is essential. However, the amount of time lost due to the lack of the right tools is trivial when compared to the delays caused by the ineffectiveness and inefficiencies in the decision processes, task prioritization, roadblocks to speed and nimbleness caused by a cumbersome process and/or the handling of conflicts within an organization.

Organization structure, leadership and investment that the company makes in the development of the organization's most vital asset - the people - are usually at the heart of the problem. You should ask the yourself the following questions about the company environment as a whole:

- How many people have to review a job before it is released to the shop and how much time is consumed?

- How many meetings are going on within the company at any one time during the day, how much time is consumed, how often is there a tangible result or outcome that can be measured and what are the real costs of having these people participate?

- How much time is lost due to wait time or queue time? (The theory of constraints applied to both the production and the business processes.)

- How do people resolve conflicts, develop consensus and collaborate with stakeholders (i.e., customers, shareholders, employees, reps and suppliers) and foster strategic thinking within the organization?

- How do you answer the question "What's in it for me?" daily before the question is asked by the staff?

- Why should someone want to follow your guidance and example?

- Is leadership a core competency within the company?

- How would you define the ideal shop operating environment and culture?

The speed and nimbleness of an organization is usually a product of process effectiveness and efficiency and the organizational culture. The cultural component is tied directly to leadership style - a mindset of those who are empowered to allocate, focus and coordinate the use of assets. Leaders set the tone for the entire operation.

Leadership is a learned skill. It is acquired through a learning process referred to as development, an adult learning technique that helps people acquire the knowledge and immediately put the practice into positive action through a series of simple but effective behavior changes. Skills learned using the development process are retained on average for at least fifteen years and, if practiced regularly, they are retained for a lifetime.

What's Your Style?

Style can be an enabler of the organization's strategy and goals. There are many different ways to categorize style as a trait or behavior. Three primary categories are those that have been defined as part of the management development program1: The Enhancer, The Neutralizer and The Diminisher.

The Enhancer

This is a person who is self-confident, respected, responsible, accountable, possesses personal power and can get others to work efficiently toward organizational goals. Those who work with the Enhancer produce because they are made to feel important, worthwhile and an integral part of the achievement of the organization's goals. The Enhancer instills commitment, rewards competence and maintains consistency, thereby developing a culture in which all can receive recognition and satisfaction in their work. Those who work beside this type of individual produce not in competition but in mutual admiration. Those who work above an Enhancer put their confidence in an individual who sees crisis as an opportunity and creates a future responsive to the bottom line and to the organization's people.

The Neutralizer

This is a person who, by some means or another, is able to get the work done. The Neutralizer has the respect of some and the contempt of others. They typically have limited self-confidence and they take accountability only for that which the organization specifically requires. People who work for the Neutralizer produce only the minimum required to get by. This type of individual hides lack of personal power behind authority which is used frequently. One can anticipate virtually everything that a Neutralizer will say given any situation. Those who work under the Neutralizer tend to toe the line while those who are peers tend to avoid them. The Neutralizer maintains a neutral climate in which to work and brings to the organization what he or she is paid to do, nothing more and nothing less.

The Diminisher

This individual lacks personal power, self-respect and the respect of others. Being somewhat irresponsible, a Diminisher tends to blame rather than take accountability and relies totally on authority and threats to intimidate subordinates to reach organizational goals - a "My way or the highway" mentality. They typically are a "yes person" to those to whom they report. The Diminisher creates an environment where very few can have their needs met. Their behavior inhibits creativity and loyalty and constrains the innovation process.

Look at each of the three management styles. What impact would each have in working with the people in your shop? Which style(s) would be most conducive to creating a motivating environment and a "can-do" team spirit? Which style(s) would look at speed and nimbleness as opportunity versus burden? How would each style impact decision processes in an organization? How would each manage conflicts and what impact might that have on a product development cycle?

Leadership style is not simply a behavior trait of those holding management titles as part of their position description. In fact, each person in an organization has a specific style of working within the structure of the organization with their counterparts and associates. Thus, each person imparts an imprint on the company's performance by both their technical performance and their behavior. Each person brands the company's processes. These, in turn, have a dramatic impact on the time and costs and whether an organization remains competitive.

Conflict Management

Most people have a very difficult time managing conflicts. In fact, the norm is to postpone or avoid conflicts wherever and whenever possible. The leader's ability to effectively cope, guide and resolve conflict - that time when one or more people disagree or have a different point of view - can have a dramatic impact on productivity. This in turn impacts capacity, costs, revenue and profit.

How do individuals handle conflict management? A good model for evaluating conflict modes is the one developed by Kenneth Thomas and Ralph Killman}. They define five conflict management modes using a scale of assertiveness and cooperativeness.

- Competing - Highly assertive, low on cooperation: The goal is to win.

- Avoiding - Low assertiveness and cooperativeness: The goal is to delay.

- Compromising - Moderate in assertiveness and cooperation: The goal is to find a middle ground.

- Collaborating - High in both assertiveness and cooperation: The goal is win/win.

- Accommodating - Low assertiveness and high cooperation: The goal is to yield.

Which of these modes of managing conflict works best for your operations? How do they impact speed and nimbleness? How would you match these modes with the three types of leadership style? Which best describes your particular general approach to managing conflict with your coworkers, management team, customers, suppliers and your family? What impact do you think that it has on results?

The people factor is fundamental to successful shop operations. It is also the key to achieving any type of competitive advantage. The age old principle that customers give us revenue and employees create profit especially holds true during this time when change is the norm. Technology and automation can play a major role in a company's ability to meet customer requirements, improve some efficiencies and develop new products and services, but these are only tools. Success always comes down to people for they are the organization. The way these leaders interact will ultimately determine the fiscal fitness and competitive strength of a business.

A good guideline to use with your company is: Would the employee that I was be proud of the employer that I am? It can work in your parenting life as well: Would the child that I was be proud of the parent that I am? These are both leadership challenges.

Take a look at your own style of people interaction and mode of managing conflict. Are you as effective as you could be? Are you truly an asset? Would you be willing to follow you? How do you deal with the Neutralizers and Diminishers in your organization? What would you change and how would you measure the results? Is it worth the journey? What happens if you don't make the journey?

What has been your experience?

Note 1: Reprinted and quoted with permission. Descriptions of the Enhancer, the Diminisher, and the Neutralizer are summaries and extractions from the program text found in Sterling's Management Development Program - cResource Associates Corporation, Publisher.

Note 2: Source: Thomas-Killman Conflict Mode Instrument, XICOM, Publisher.

Related Content

OEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

Read MoreThe Role of Social Media in Manufacturing

Charles Daniels CFO of Wepco Plastics shares insights on the role of social media in manufacturing, how to improve the “business” side of a small mold shop and continually developing culture.

Read MoreThink Safety: Eliminate Hazards Throughout the Shop

The tooling community is taking advantage of new products for safer mold shops and molding facilities.

Read MoreTackling a Mold Designer Shortage

Survey findings reveal a shortage of skilled mold designers and engineers in the moldmaking community, calling for intervention through educational programs and exploration of training alternatives while seeking input from those who have addressed the issue successfully.

Read MoreRead Next

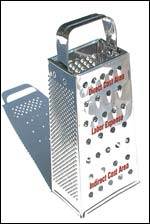

A Cost Structure Cheese Grater for Businesses

A quick, simple and inexpensive method of computing the indirect costs for pricing, bidding and estimating for small shops.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)