Women Impacting Moldmaking

Honoring female makers, innovators and leaders who are influencing our industry's future.

MoldMaking Technology magazine is honoring and celebrating the women who help make moldmaking such a dynamic industry. Each of our honorees has made a lasting impact on her company, earning leadership roles that keep our industry moving forward. They are women driving innovation, changing culture, breaking barriers, working hard, instilling passion and energizing the next generation of women in moldmaking.

Each woman was recommended by industry peers when the concept of this special feature was introduced. The hope is that this inaugural female-focused spotlight will entice others to contact us about women worthy of being recognized and enable us to do this again in the future.

We set out to discover how these women got to where they are today, to learn about their biggest contributions to their companies and to the industry, to understand how they see their roles evolving in the future, and to hear what they believe is the key to bringing more women into moldmaking.

We consider this month’s honorees our Core Contributors, representing owners, managers, designers and shopfloor personnel. Next month’s honorees are Support Pillars, who serve in marketing, training and administrative roles.

Donna Pursell says she believes in leading by example and with purpose. “I help mold the company’s culture and keep our values always in sight by promoting positivity, trust and honesty,” she says. Her passion for the industry was fueled by her first husband, Mike Koebel, who was a lead moldmaker at a shop in Upland, California, once a popular region for mold manufacturing companies. They established Prestige Mold together in 1982. Donna credits Mike with laying the foundation for success at Prestige because he was not only passionate about the industry but well-respected for leading the company with creativity and integrity. Though Mike is no longer there (he lost a courageous battle with cancer in 1998; Donna remarried in 2006, to Kenneth Pursell), Donna carries that passion still.

As CEO of Prestige Mold and president of Pres-Tek Plastics Inc., a mold development center and an ISO 13485:2003-certified Class 8 clean room for production located next door to Prestige, Donna says she is responsible for the success or failure of both companies, and it’s a role she does not take lightly. In fact, she believes her most significant contribution to the industry is providing steady, challenging work for more than 120 employees so that they can provide for their families. She oversees the high-level financial operations. “This is not something that I feel I can delegate, because I know the level of risk that I’m comfortable with,” she says. Donna also oversees and helps to build the executive team, which she says is composed of hard-working, intelligent people that she is proud to work side by side with.

Donna adds that, with the pressures and commitments of two companies, she knows her time can be stretched very thin, and she realizes now, more than ever, the importance of having strong team members in key positions. “As we continue to grow, I will be more focused on grooming the right people for those positions to ensure our success in the industry for years to come,” she says. As for bringing more women into the industry, Donna believes exposure is key, because this isn’t the old-school manufacturing world. She thinks the best chance for bringing more women into the industry is through an introduction to engineering, mold design, metrology and inspection, and injection molding simulation software.

Patricia Miller’s rules to live by include having a passion for manufacturing and making physical products, bringing outside perspective and experience to the table, and not being fearful to challenge the status quo.

Patricia officially joined the manufacturing industry in July 2014 when she became the owner and CEO of Matrix 4, but her love for manufacturing came much sooner. She grew up with Matrix 4 as a family company her grandparents started in 1976, with her mom working in manufacturing and process engineering. Patricia says she always loved seeing what was being made. She became more fascinated with manufacturing when she joined the pharmaceutical/biotech industry and was tasked with auditing manufacturing facilities, visiting pharmacy dispensaries and observing different manufacturing processes. When the opportunity to take over and revitalize Matrix 4 opened up, she says she couldn’t say no.

She set out to establish a vision and strategy for the company, to create an engaging culture, and to instill business acumen and an open-mindedness for doing something different in a traditional space. She describes Matrix 4 as a 40-year-old startup, because she and the rest of leadership took this shell of a business that at one time was vibrant, but due to post-recession and globalization was nearing the end of its life, and decided to do something with it. Today, Matrix 4 is a team-driven, customer-centric design and manufacturing house and maker of plastic.

Above all, Patricia is a huge advocate for having the right people in the right seats, but creating an environment and culture to be inclusive, diverse and open-minded is critical. Matrix 4 is woman-owned, and most of the team is women. “Growing up with a mom who worked on the manufacturing floor and never believed in a ceiling absolutely helped define me, and her legacy is still very much in our culture,” Patricia says.

Patricia hopes that what is still a work in progress becomes her greatest contribution, because it can impact local economy, people’s lives and products that are meaningful. She sees herself continuing to be engaged and driving the strategy and culture of the house, and staying actively engaged in industry activity, “as we all write the next chapter of manufacturing together.”

Carol Klingler Ebel is deeply committed to her family, her family’s company, Janler Corp., and the moldmaking industry. Janler turns 65 years old this year, and Carol says she feels fortunate to have held the reigns as president for the past 25 years. Her father, the late Josef Klingler, led the company for more than 40 years before her. Her path to the moldmaking industry was somewhat traditional in that she was mentored by the many men in her family, starting with her dad, uncles and brothers.

“The mentoring was both technical and about the traditions of the industry, including the critical trust component of customer relationships, knowledge and respect for your supplier base, the unique relationships with friendly competitors, and the benefits of your personal commitment to the industry through giving back and sharing. The more you give, the more you receive,” she says.

Carol sees herself as the visionary for Janler, keeping a watchful eye on new trends in business, technologies, foreign policy and other global developments that may have an impact on the company. Her background in economics and accounting (she became a certified public accountant and later earned a master’s degree in management from Northwestern University) has served her well at Janler. She also has valuable training in risk assessment while doing strategic business planning. “I came back to Chicago for graduate school and to consult with my father about the growing pains of his moldmaking and molding company. The timing was good, because my skill set ended up being a pretty good fit,” Carol explains. Using a professional business approach to run Janler has helped the company succeed, and her optimism and prior business experience helped the company overcome various challenges with both change and people management.

Carol looks to provide guidance and counsel to others while they seek to create their own career paths. “I want to spend more time inspiring others, maybe teaching or speaking to share my message about U.S. manufacturing. I have so much pride in what I do and what I have been able to accomplish, and I want others to have the same opportunities,” she says.

Francine Petrucci grew up in the mold manufacturing industry, beginning in her pre-teens working part time at her father’s shop, BA Die Mold. After graduating cum laude with a bachelor’s degree from Northern Illinois University’s School of Engineering, where she was one of the only women in the program, she began her full-time career at BA. Francine worked in the company’s CNC and quality assurance departments, then through administrative roles in the office to now serving as the company’s president and co-owner. In her role, she oversees general corporate management, building and equipment management/maintenance, corporate marketing and customer relations, and, as she puts it, “selfless promotion of our trade!”

Francine takes pride in providing a woman’s touch to every aspect of her company’s operations. “Female engineers bring a different perspective to projects and how we approach them. This is invaluable, particularly since I work in an almost 100-percent male-dominated industry,” she says.

In addition to fulfilling her lifelong pursuit to work in an industry she loves, Francine has been an active member and on the board of directors of the Chicago chapter of the American Mold Builder’s Association since 2003. In 2012, she accepted the role of chapter president and just passed the gavel to a new chapter president in March. Over the years, Francine has met with Illinois and federal legislators about rebuilding American manufacturing, and she continues to make them aware of policies that are hurting domestic manufacturing. Francine has also worked with competing companies to better the overall working environment for manufacturing businesses.

A tireless promoter of mold manufacturing as a viable career to young women and young men alike, including a speaking engagement at a local high school where she shared her experiences as a woman working in a nontraditional career for women, Francine established the first Education Committee for the AMBA Chicago Chapter. She has enthusiastically led that group in achieving its goals, including creating a website (moldyourcareer.org) and brochure emphasizing the rewarding aspects of working in manufacturing. Francine was also instrumental in the chapter’s ability to exhibit at the 2014 IMTS Smartforce Student Summit to educate the young adults, teachers, counselors and parents in attendance about mold manufacturing.

In 2016, Francine was honored with the Illinois Technology & Manufacturing Association’s Rose Mottl Leadership in Manufacturing Award for her work to advance the manufacturing industry and for serving as an inspiration to current and future generations of women in manufacturing.

Twenty-three years ago, Monika Frary was a single mom looking to start a career. She answered an ad in the paper for a person to sell products to the plastic processing industry and was hired on the spot by Thermal-Tech’s founder and her mentor, Marshall Harmon.

“Lucky for me, I not only found my passion, but the opportunity to support all areas of the business as a key sales person, engineer, R&D inventor, manager and a leader,” Monika says. On top of that, Harmon’s complete support allowed her to develop an entirely new hot runner repair division within the company. “I am so honored that he further entrusted me to carry on his legacy when he passed away from a long-term illness in 2004.”

As its CEO, Monika has helped Thermal-Tech evolve into a leading services and products supplier to the injection molding and hot runner industries. She believes her biggest contribution to the industry is helping to grow a one-stop shop with in-house tooling experts, products and services designed to create top-notch maintenance plans that prevent shut-down emergencies for all hot runner systems and tooling needs.

Monika continues to focus the company on building customer relationships, solving problems and expanding a support system for molders dedicated to using hot runner tooling. She says her greatest joys have been mentoring the company’s growing team, listening to customers and expanding its service model as a leading hot runner refurbishment service. She believes the building blocks of any successful business are the people who contribute to playing a big game. “I’m fortunate and honored to work with a talented team who puts customers first and is always ready for a challenge,” she says.

To bring more women onto manufacturing industries, Monika believes it is essential for young women to maintain a commitment to learning and exploring so they can find their passion and carve out a powerful career path.

She says her job has been “a career of a lifetime,” so she remains on the lookout for women to hire who have a mechanical aptitude and a hunger to create a career that contributes to others in this unique industry.

Stacey Bales says she had to grow up rather quickly and learn a lot fast while in her twenties. This was because her father, Steve Bales, passed away suddenly in 2009, leaving the fate of his mold plating and polishing business, then called Bales Mold Service, in her hands and those of her sister, Sara. But Stacey had formed an early attachment to the business her father built. “I grew up at my dad’s company. I would ride my bike there in the summer and hang out in my dad’s office on sick days. He always had a fun project for us, like masking off pieces of glass and sandblasting them to create art,” she says.

Over 20 years, Stacey also cleaned offices, masked metal parts, packaged shipments, filed invoices and performed just about every other function between the shop floor and the front office. These experiences served her well when she was thrust into a leadership position, but it still wasn’t easy, she affirms.

To help keep the company going, Stacey took business and accounting classes to better understand the business side. She learned how to communicate better and facilitate teamwork. She became involved with local associations and quickly realized how important it is to have a solid network of trusted mentors and advisors to turn to, sometimes just to have an outlet to vent. She and her sister also rebranded Bales, calling it Bales Metal Surface Solutions to reflect a wider variety of services offered. Stacey is particularly involved with the Illinois Technology and Manufacturing Association’s (TMA) Young Leaders committee, where she helps get young professionals engaged with the manufacturing industry. She also served a term on the TMA’s board of directors and was honored with the organization’s first Young Leaders Award, which happens to be named after her.

As her role at Bales evolves, Stacey continues to work on her company’s future growth, and she says she will continue to promote manufacturing as a career. She says the key to drawing more women into the trade is “reaching them while they’re young. My daughter’s junior high school offered a vacuum forming program through a STEM class. She and her friends couldn’t contain their excitement about what they had seen and learned, and that’s key.”

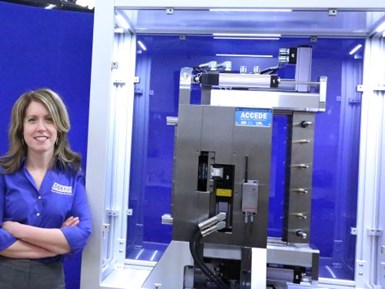

Camille Sackett grew up in Westchester County, New York, with three generations working at the Tarrytown General Motors plant. Her mother worked on an assembly line installing windshields, her great-uncle was an electrical technician, and her great-grandfather was a millwright. Touring the GM plant as a child, Camille developed fondness and respect for manufacturing. After working for Eastman Kodak as an engineering intern, she started with family-owned Accede Mold & Tool in 1993.

Camille was looking for a college freshman co-op/internship upon graduating from a technical high school where she studied architectural and mechanical drafting. A friend in Accede’s moldmaker apprenticeship program recommended that she interview with the engineering manager. The interview went well, and nearly 24 years later she has grown to be a leader and integral part of the Accede team.

Camille has served as a drafting/presentation engineer, senior mold design engineer, second-shift engineering manager, quality management system (ISO) manager, in “before-the-order” engineering and quoting, director of business development and engineering support, and most recently, as vice president of Sales and Project Management. Today, she is proud to be a part of Accede’s senior leadership team. Her help in developing Accede’s QMS processes has been her greatest contribution, according to the Accede team.

“With three children—a daughter in high school, a son in middle school and a son in elementary school—I am vocal in promoting U.S. moldmaking and the plastics industry,” Camille says. Among other things, she runs school district technology-based clubs, shares industry promotional videos, and continually touts the excitement and opportunity within manufacturing, specifically moldmaking.

“When college students stop by our booth at events, I make time to share my enthusiasm for moldmaking, especially the fulfillment that comes from working for a fast-paced and innovative company like Accede, Camille says.

When it comes to her future, Camille seeks to be more active with industry trade groups, working to advocate for U.S moldmaking and manufacturing, as education and promotion are key to bringing more women into plastics and moldmaking. “Moldmaking has evolved over the last decade, as it transitions into the era of Industry 4.0. I am excited and optimistic for future generations to continue to push and challenge the boundaries of moldmaking.”

Renee Nehls is all about injection molds, promoting the industry and blazing a trail for up-and-coming manufacturing professionals who happen to be women. Unlike many industry people before her, Renee didn’t have a parent or grandparent who designed or built molds influencing her career choices. Instead, it was an industrial arts teacher who recognized her strong mechanical aptitude and helped steer her toward a career in manufacturing engineering.

Renee’s career in the plastics industry spans nearly 30 years. More than 20 of those years were spent in mold design, with the balance in product design and development. In her role as tooling engineer at Sussex IM, a company specializing in custom injection molding and full-service, integrated manufacturing, she evaluated customers’ product designs for manufacturability. She also procured new molds, analyzing their designs to ensure optimal function and performance according to customer specifications. Her biggest contribution to the company? Real-life, thorough comprehension of the mold design and build process.

For Renee, who now works as a tooling engineer at Orbis Corp. in Oconomowoc, Wisconsin, continuous improvement is more than just a company mantra; it’s a personal quest. She keeps her mold design and product development skills honed by taking classes through the University of Wisconsin system, and she also regularly attends technical conferences such as those offered by the Society of Plastics Engineers (SPE), in which she has been an active member since 1988. Her SPE involvement includes serving as an elected Milwaukee section board member since 2011, including a term as that section’s president. She is also an elected board member of the SPE’s Mold Technologies Division. “Through my involvement with the SPE, I’m able to help spread knowledge and strengthen skills in the industry.

My journey has been vibrant, but not without nontraditional obstacles. It is important to me to provide guidance to women entering the industry so that they don’t have to misspend energy figuring out how to navigate on their own.”

In her spare time, Renee can be found mentoring high school and college athletes throughout the state of Wisconsin. She herself is a rugby enthusiast and has played for many years. As with moldmaking, rugby is regarded by some as too rough for women, but Renee’s not having any of it, saying, “We have to break the women-in-moldmaking stigmas!”

Brenda Clark began her career as a mold designer during her senior year of high school, when she found a small shop in East Hartford, Connecticut, that built connector molds for desktop computers, among other products. She says the owners agreed to begin training her and then help with her college education once she graduated from high school. She attended Hartford State Technical College and earned associate degrees in machine design and mechanical technology. “I never anticipated that I would advance as far as I have and love this industry as much as I do,” she says. “My grandfather was an accomplished tool and die designer and machinist, so I believe this is what I was meant to do.”

The owners of that shop gave Brenda exposure to every aspect of mold design, as well as to mold building and processing. They allowed her to work in the office, in design and on the shop floor making chips, and to run an Arburg Allrounder 200 molding machine. She says that she’ll be forever grateful for the opportunity and for their belief in her. It’s this kind of mentorship that she believes is needed to bring more women into the trade. “The sooner we can introduce young women to career options in manufacturing, the more likely they will pursue it and excel,” she says.

For the past 12 years, Brenda has worked for Hasco America, where she currently serves as the engineering manager, working with the inside sales team to answer customers’ technical questions about such things as mold plates and components, mold designs, hot runner system designs, and more (in both inch and metric specifications). She also provides technical instruction via Designer Days events and on site at customers’ facilities. She believes her knowledge and technical background are her greatest asset in her role at Hasco, because it helps customers build better molds and programs. As for contributions to the industry at large, Brenda enjoys giving technical presentations that support and inform mold designing and building. Her desire is to promote technical learning, and she currently serves as technical program chair for the Society of Plastics Engineers Mold Technologies Division and is also the division’s chair-elect.

From a young age, Kristina Bollinger says she had an interest in mechanical engineering. She grew up helping her grandfather disassemble, repair and rebuild small engines. He was her first and as Kristina notes, “probably toughest,” boss. He expected her to show up on time and be ready to work—no excuses. “Making my grandfather proud was much more rewarding than earning a paycheck each weekend,” she says.

Kristina grew up in Sayler Park, a small town outside of Cincinnati, Ohio, playing sports, going to school and working. She says she was raised to be responsible and encouraged to be the best person possible. She says her family has been instrumental in getting her to where she is today.

After graduating early from high school, Kristina was accepted into Northern Kentucky University’s mechanical engineering program. About a year into the program, she signed on for a co-op position at an aerospace manufacturing facility, which quickly led to a full-time job as an assistant in its metallurgical technology laboratory. After a year, she returned to school at Cincinnati State Technical and Community College to complete two mechanical engineering degrees in manufacturing and design. Shortly before graduation, Kristina landed another full-time job in the aerospace field, where she remained for a little more than two years on a project that involved production scheduling, process instructions and quality tests.

On the hunt for something new and more challenging, she began working at a startup company under Procter and Gamble called iMFlux, which develops injection molding “industry-changing” technology. There, she has been given the chance to broaden her engineering knowledge as a process engineer.

“Previously, I only dealt with metals and ceramics, but this job entails a broad range of plastics for which I needed to learn their specific properties and the necessary techniques to improve processing,” Kristina says.

Today, she trains both internal employees and in-field customers, and tries to meet customer expectations for cycle time and part weight reduction, and part-quality improvements.

She believes the drive to succeed is what is required of women in moldmaking and plastics. Colleagues say that it doesn’t matter whether the job falls outside of her job description or requires longer hours than planned, if work needs to be done, Kristina is always willing to lend a hand. This 26-year-old’s ability to work well with others, and competently and reliably work solo, has been the secret to her success so far.

Related Content

Mold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.

Read MoreMMT Chats: Solving Schedule and Capacity Challenges With ERP

For this MMT Chat, my guests hail from Omega Tool of Menomonee Falls, Wisconsin, who share their journey with using enterprise resource planning (ERP)—and their people—to solve their schedule and capacity load monitoring challenges.

Read MoreMaking Quick and Easy Kaizen Work for Your Shop

Within each person is unlimited creative potential to improve shop operations.

Read MorePredictive Manufacturing Moves Mold Builder into Advanced Medical Component Manufacturing

From a hot rod hobby, medical molds and shop performance to technology extremes, key relationships and a growth strategy, it’s obvious details matter at Eden Tool.

Read MoreRead Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More