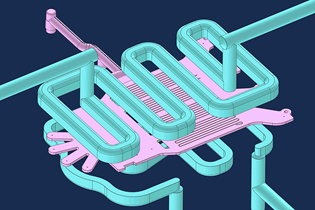

Injection molding is one of the most widely used manufacturing methods due to its ability to produce high-quality parts at incredibly high volumes. However, the productivity of these processes is often limited by the cooling methods that removes heat from the part after molding. Advancements in additive manufacturing (AM) techniques have opened the door for new approaches suitable for production molding. Modern conformal cooling approaches achieved through these AM techniques offer the potential for breakthrough solutions.

This webinar will explore the cutting-edge advancements in these technologies that enable the design and production of intricately-tailored cooling channels within injection molding tooling. During this session, SyBridge Technologies will discuss its approach to design, simulate and test novel cooling structures to improve injection molding tooling performance from cycle time to warp.

.jpg;maxWidth=300;quality=90)