Mold builders need a systematic process that allows the business to repeatedly (and with confidence) make decisions about what to improve on an ongoing basis. Photo Credit, all images: Science of Business Inc.

This is the fourth and final installment in our series of articles. We’ve covered a wide range of topics and how those topics affect the moldmaking industry, ranging from pricing to marketing to technology. And, if you’re like most business owners, you recognize that there’s no shortage of “good” ideas that could be implemented. Given the range of alternatives, the question that emerges is: What should I be doing?

Now, as Theory of Constraints (TOC) practitioners, we would tell you to start by making improvements at your constraint, or if we thought about your business in terms of a chain, it would be at the “weakest link.” If you improve anything other than the constraint, you’re liable to have limited/no impact, if not a negative impact (in fact, many “investments” aren’t investments at all. They neither generate returns nor pay for themselves — ever!).

Well, that sounds good, in theory, but where is the “weakest link” in your shop? After all, you run a mold shop and your mix is constantly changing. One day your constraint is at the EDM department, the next it’s machining, then it is engineering and then it is polishing. The constraint is constantly moving.

A disruption to flow is anything that interrupts the output of the constraint or the system as a whole.

Output is dictated by your constraint. To get more out, you’ve got to get more through the constraint. However, that’s easier said than done at a shop where the constraint can move week to week or even daily. The fact that the constraint moves in your shop is common. However, despite this fact, management should still manage around the constraint, not by consensus or committee.

And, speaking of your shop, despite seeing or reading about all the great ideas that are out there, the reality is that you will need to make these improvements in your business.

Whatever great idea you select, it must work at your business, which is unique, different and special. It’s anything but simple or the clear-cut textbook case studies that are commonly presented. You actually have customers and employees to deal with — and neither one of these are just willing to go along with anything you say. Whatever you do will need to work — and still allow you to keep the business operations running smoothly.

How to Find What Will Work at Your Shop

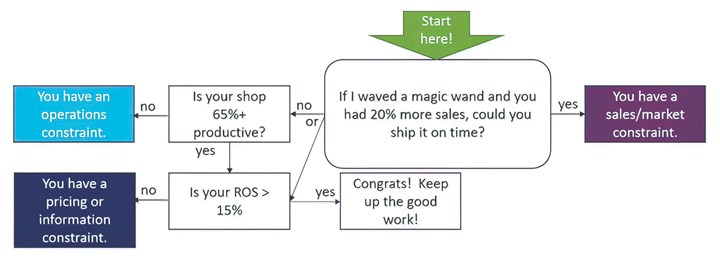

So, how do you find the very few, or one thing, that you should focus on? The one thing that will actually make a difference (i.e., increase the bottom line) at your shop?

Deciding what and where to improve may feel overwhelming, but finding what to focus on isn’t too difficult. Plus, when you have focus, you’ll be able to overcome any overwhelming feeling you might have. Let’s examine what we know so far:

- The solution must be directly applicable to your business.

- The solution must actually be an improvement, as measured by your bottom line.

- The solution/improvement/idea must save more time and money than what is required to implement it (otherwise, why would you do it?).

Unfortunately, what most people do at this point in the decision-making process is something like a “brainstorming session,” a SWOT analysis or go off site to have a “strategic planning session.” These are simply buzzwords that mask the fact that we do not have an effective method to make a decision about what to do at our shop ... wait a second.

Now that’s an interesting thought. What if there were a repeatable, systematic method for making these decisions? Let’s add one more requirement to our list:

We have a systematic process that allows us to repeatedly (and with confidence) make decisions about what to improve on an ongoing basis.

You probably won’t believe this, but believe it or not, there is in fact just such a thing that exists. It’s called: POOGI. POOGI? POOGI!??? POOGI = The Process of Ongoing Improvement.

The Process of Ongoing Improvement

POOGI is a systematic process that identifies interruptions to flow in your shop, based on what’s actually occurring at your shop.

POOGI is the answer we’ve been looking for. We all have a tool belt that is just full of good tools … Lean, Six Sigma, ERPs, scheduling, engineering tricks, fixturing systems, new machine tools, you name it, we’ve got it. The problem is that we’ve never had a focusing mechanism to tell us which tool to apply (and when, where and how) to our businesses. That’s what POOGI is.

The best part about using POOGI is that it’s not a “great concept” that won’t work at your business. It’s a process that uses real-world information based on what’s happening in your business to identify what problem to focus on fixing and improving. Thus, we know the first criteria is that the solution must be directly applicable to your business. After all, POOGI uses what is going on in your business to tell you what to focus on.

Second, because POOGI is based on the actual real-world events in your shop, the POOGI process will identify the largest disruptions to flow in your shop, so when you make improvements, you can get more jobs through the constraint. That means you complete, ship and invoice more jobs in the same period of time. And if you can complete, ship and invoice more jobs in the same period of time (with the same operating expenses), then we know the bottom line will improve.

As POOGI is the Process of Ongoing Improvement, this means we’ve not only “done something” once in our business, but instead we’ve instituted a process that will allow us to make repeated improvements in the business.

Third, again, because POOGI is built on what’s actually occurring at your shop, then we know when we make an improvement, we’ll be tackling the largest issue that’s currently facing your business. The effect of doing so is to “free” the business from the heaviest weight that’s holding it back. This means once you make the improvement that POOGI is guiding you to make, you’ll have more money in the bank and have freed up more time (capacity) in your business. Win-win.

And finally, as POOGI is the Process of Ongoing Improvement, this means we’ve not only “done something” once in our business, but instead we’ve instituted a process that will allow us to make repeated improvements in the business.

Track disruptions to flow as they occur in a visual system like the Velocity Scheduling System to discover the “why.”

How to Do POOGI

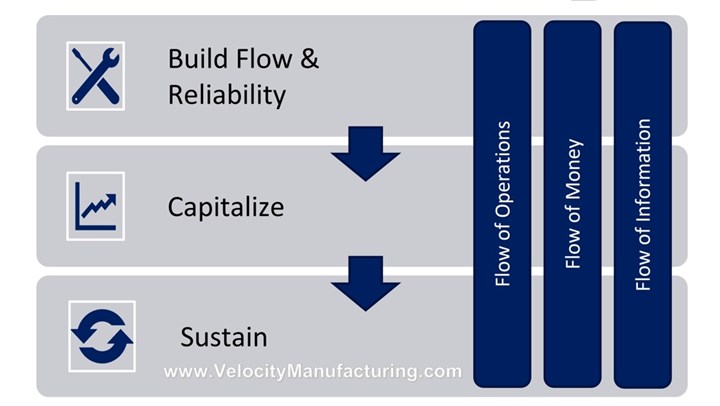

To tell you where and how to begin tracking disruptions to flow, it’s important to understand the three primary flows in any business: the flow of information, the flow of operations (a.k.a., physical flow, material flow and/or logistical flow) and the flow of money.

The flow of information is just that. It is the flow of the information required to take an order, fulfill an order and ultimately charge the customer for an order. It’s all the details on the customer’s purchase order, the plans, specs, any approvals required and requirements for delivering their order to their desired location. It also includes the information you need to send them an invoice (not always an easy process!).

The flow of operations can also be thought of as physical or logistical flow. It is the flow that takes raw material and converts that raw material into a component or complete product. In the case of moldmaking, this is the flow that manufactures the various components of a mold (e.g., mold base, cores, hot runner systems, side actions, etc.) and assembles them into a final mold.

Now, if your business has services that it offers that do not generate an end product, per se, this would be the process you have to go through to render the service to a customer. For instance, if a customer wants you to come on site and diagnose their issues with a mold, the flow of operations would be things like scheduling a technician/moldmaker to go on site, making travel arrangements, performing the diagnostic service. Essentially, the flow of operations envelopes those tasks you must do to make money, whether you’re making a physical product or providing a service.

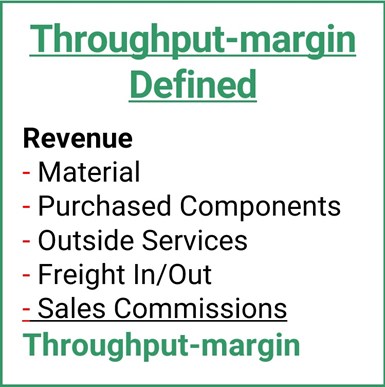

That brings us to our final, and perhaps the most important flow, the flow of money. Every job, product or service your business provides generates some level of money flow (ideally). We call the money flow that each job, product or service generates throughput-margin.

The money flow that each job, product or service generates is call throughput-margin.

Throughput-margin is simply the job, product or service’s Revenue minus Material, Purchased Components, Outside Services, Freight In/Out, Packaging and Sales Commission. That’s all we need to know to see money flow. It’s much simpler than trying to do gymnastics with cost accounting.

Now, money flow is a bit more difficult to see than the other flows. For example, if you don’t have the plans (information) for how to build a mold, that’s going to stop you from making the components of the mold (physical). Thus, information and physical flow are very easy to see and track disruptions to them.

But what about money flow? What if you didn’t charge enough for the job or service you’re providing? How do you see that? And, what constitutes a disruption to this flow? Don’t sweat it just yet, we’ll give you some examples of disruptions to the flow of money later that you can use for your POOGI efforts.

Ultimately, it’s the flow of money that dictates your profitability in any period of time. However, it’s almost totally dependent on the flow of material and the flow of information in the business. For example, if you don’t finish a job (flow of material) because you don’t have the required tolerances from your customer (flow of information) then you can’t invoice the customer for the job (flow of money). That’s why it is so critical to track the disruptions to any of the three flows, as any disruption in any one of these three flows could negatively impact your bottom line.

Tracking Disruptions and Assembling a Team

Now that we know about the three flows in your business, let’s get back to tracking disruptions. A disruption to flow is anything that interrupts the output of the constraint or the system as a whole. Here are some examples where the disruption causes the constraint to go idle or shipment to be delayed:

- We are missing raw material for a job.

- We don’t have all the tools needed for a job.

- We don’t have approved drawings for a job.

- We are missing information from the customer for a job.

- We’re not sure how the CNC programmer wanted the machine set up for a job.

- Drawings were released, but they’re incomplete or have conflicting tolerances/specs for a job.

It’s best to track disruptions to flow as they occur like we do in Velocity Scheduling System. But, if you don’t have a similar visual system and missed tracking those, then when the job is ultimately late, find out why. Typically, it will be a combination of things. A great tool to capture all the reasons for why the job was late — those disruptions to flow — comes to us from Lean, the Five Whys. For example:

- A job was late. WHY? We overcommitted our capacity.

- A job was late. WHY? An important machine broke down.

- A job was late. WHY? Key workers were absent (could be due to sickness, family vacation, bereavement, etc.).

- A job was late. WHY? Raw materials arrived late.

- A job was late. WHY? We were missing information from the customer.

We recommend doing both. Track the disruptions as they occur (using the Five Whys for these as well) but also use the Five Whys when a job is shipped late. You will often identify additional disruptions.

Tracking the disruptions is a huge first step. The next step is to assemble a POOGI team, who will categorize and review the disruptions. You’ll soon discover that most disruptions will generally fall into about 10-15 different categories of problems. The POOGI team will then identify your biggest disruption to flow. Once identified, they are responsible for eliminating/reducing this biggest disruption to flow. In this way there is one improvement project for your limited resources, not 20. And this one project is guaranteed to improve flow.

The POOGI team should comprise a cross-functional group of managers. This synchronizes our efforts across the business and builds alignment as your management team is all working on the same key priority, which is the priority for the business as a whole.

Velocity Manufacturing

We call this process of managing the three flows in your business Velocity Manufacturing. The reason it’s called Velocity Manufacturing is that this method of management is completely focused on one thing: increasing the speed of flow in your business. And, unlike conventional management methods, the Velocity Manufacturing System is a completely integrated, holistic approach to improvement, built around POOGI.

This is why Velocity Manufacturing is so effective and it’s also why so many great tools (e.g., Lean Six Sigma, new technologies, etc.) become a “flavor of the month.” So many great tools have fallen by the wayside because we have been missing the focusing mechanism that directs us where, when, how and why to use them in our business to make more money. For example, Lean tells us to reduce waste. But, where? Everywhere. Six Sigma tells us to reduce variation. But where? Everywhere.

Velocity Manufacturing is a method of management that is completely focused on one thing: increasing the speed of flow in your business.

Lean and Six Sigma are much more impactful when applied to your biggest disruption to flow. So, we’re not throwing out all these great tools, we’re simply applying them when and where they’re needed the most (just like how we used the Five Whys to aid in tracking disruptions).

A common approach to continuous improvement is using the 80/20 rule, where it’s thought that 20% of the problems will give you 80% of the impact. With Velocity Manufacturing, in using the POOGI process, we actually find that the ratio is more like 99/1! This is because POOGI is focused on the constraint in your business. The 99/1 leverage you get when using POOGI comes from the fact that the improvements generated by the POOGI process are those that affect the constraint and therefore the bottom line.

Hopefully this article revealed how the use of POOGI can guide your improvement and investment efforts. In our prior articles, we discussed some of the most common improvements which tend to greatly increase the velocity of the three flows in our customers’ businesses. Despite how great any improvement might be, it needs to be done in the context of the business, which is to say it must be directed at the business’ constraint. And that’s the power of the Velocity Manufacturing System. It is built upon the use of POOGI to maximize the velocity of the three flows in your business, so that you can maximize your Net Profit.

Related Content

The Trifecta of Competitive Toolmaking

Process, technology and people form the foundations of the business philosophy in place at Eifel Mold & Engineering.

Read MoreOEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

Read MoreThe Role of Social Media in Manufacturing

Charles Daniels CFO of Wepco Plastics shares insights on the role of social media in manufacturing, how to improve the “business” side of a small mold shop and continually developing culture.

Read MoreHow to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

Read MoreRead Next

Four Questions to Ask Before Your Next Technology Purchase

Understanding the limitations of your operation is vital to buying and implementing new products, equipment and services.

Read MoreFour-Step Formula for Mold Builders to Use in Their Marketing That Increases Sales

The most common marketing mistakes, some key marketing questions to land new business and how the Theory of Constraints applies to marketing within the small to midsize manufacturer.

Read MoreA Different Approach to Pricing

A cost-based approach to pricing used in moldmaking is the fundamental flaw causing net profits to be less than 10% of sales. There is another option.

Read More

.jpg;maxWidth=300;quality=90)