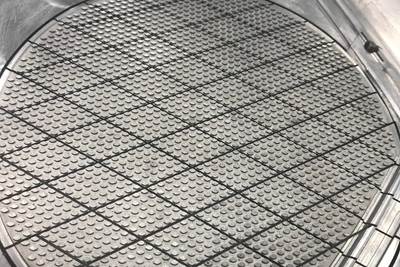

The design freedom offered by additive manufacturing (AM) is an unmatched advantage compared to injection molding. The HP Multi Jet Fusion technology shown above can print the entire combination of parts into one printed object, eliminating any stack tolerances and enabling unique iteration and greater world reach quickly. Photo Credit: HP Inc.

Additive manufacturing (AM)—also referred to as 3D printing—is becoming an increasingly valuable counterpart to injection molding. Once seen as a novelty for prototyping, AM has established its unique importance in producing a wide variety of parts. It contributes to an injection molder’s profitability through high-margin bridge molding, part count reduction, quick-to-market commercialization and the manufacturing of very complex, expensive parts.

This is why AM is growing by 20% a year—and that’s just for prototyping. For serial production of real parts, AM has increased by nearly 50% each year for the past three years. Three years ago, people were asking questions like, “Can you print this part?” and today, they are asking, “Can you make 10,000 of these parts, consistently within this very tight tolerance?”

AM, working in tandem with injection molding, owes its rapid growth and increasing variety of applications to a combination of technological advances, design freedom and significant economic and supply chain benefits.

AM Tolerances and Material Properties Match Molding

Today’s possibilities with AM are markedly better than four or five years ago and certainly better than two years ago. Of course, for a single-component part, AM can’t quite match the tolerances obtained with precision molding or hard steel, but it’s not always about a single component.

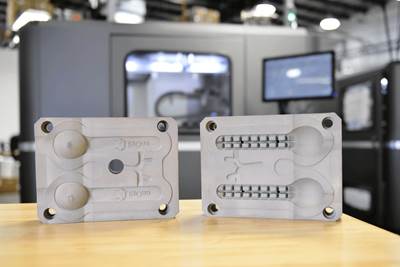

The limitations of injection molding design due to draft angles and pull directions often require combining several simpler parts into a single part through mating surfaces and screws. In those cases, the stack tolerance of the finished object is the sum of the tolerances of each individual part.

AM’s design freedom allows the ability to print the entire combination of parts into one printed object, eliminating any stack tolerances. In addition, the process will enable one to combine complex geometries into one part, which results in better tolerances compared to a multiple-piece injection-molded part.

Although AM may still produce items with slightly less density, its properties are becoming almost identical with injection molding material. AM processing conditions can correct this deficit, but doing so adds to processing time, which costs money. One must also remember that most injection-molded parts have a weld line—known to cause strength reductions of 20-60%. AM parts do not have weld lines and can produce stronger parts than injection-molded parts with significant weld lines.

With AM, it is more important to iterate quickly. For example, a cooling duct was redesigned from a six-piece injection-molded cooling duct into a single-piece duct. By redesigning into a single-piece duct, AM reduced the cost by a third and increased manufacturing time.

Unique Ability to Iterate

AM offers a design freedom advantage compared to injection molding. For example, a part with a dead sharp corner will be weak. To add a radius in a mold for injection molding, you must consider the cost of machining a larger radius, plus the limitation of the radius size to obtain a decent cycle time and prevent warpage from occurring. On the other hand, there are no design restrictions to a printed radius.

If you make a mistake with an injection mold, it may take 12 weeks to correct. With AM, you can correct an error and print again in less than 12 hours.

An increased radius does not add cost because there are no tooling considerations. And because no molded-in stresses occur (AM has zero shear rates), you can design a generous radius without warpage becoming an issue.

Lately, a “pre-deformation” technology has advanced to the point where you can scan a part, compare it to the original CAD file and make automatic adjustments to the CAD file to compensate for the out-of-spec dimension. Then, within 12 hours, you can print a “pre-deformed” part to prove that the final dimensions are within specification.

For AM, it is more important to iterate quickly rather than get it correct the first time. For example, if you make a mistake with an injection mold, it may take 12 weeks to correct. With AM, you can correct an error and print again in less than 12 hours.

For example, for a printer, we redesigned a six-piece injection-molded cooling duct into a single-piece duct. The price to injection mold and assemble the pieces was $29.79 per duct. By redesigning into a single-piece duct, AM reduced the cost by a third, to $19.58. Plus, we could start manufacturing immediately rather than wait 16 weeks for tooling.

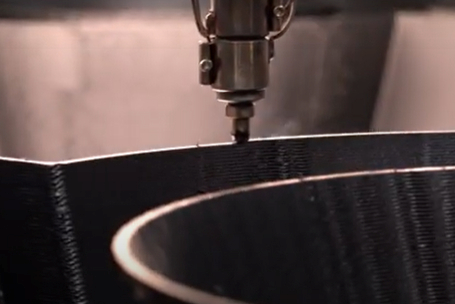

Unfortunately, the first air duct design was restricting airflow, and the printer was not cooling sufficiently. We had two choices: a more powerful fan motor or a redesigned duct. Computational fluid dynamics (CFD) showed that airflow would improve if we altered the duct to take on a more organic shape with fewer sharp angles to reduce pressure drops.

We used a software integration of CFD and generative design to create a unique, organic design that reduced air restrictions. The new, organic-shaped part with optimized flow could not be produced with injection molding, but it improved airflow by 22.3% and was still less expensive than the original injection-molded part.

AM can introduce urgently needed resiliency into supply chains. In the early part of the pandemic, there was a shortage of face shields. Within less than a week, HP printed and assembled the first face shield design and had the design certified and shared with hundreds of different digital manufacturers across the globe within two weeks.

More Resilient, Localized Supply Chain with Global Reach

The potential that exists when AM is used alongside injection molding is massive. Custom molders can now use this process to get high margins on low volumes of work (bridge molding), which is work they may have had to turn down before.

With injection molding, tooling represents an investment that must be paid off before you can make any profit. As a result, injection molding becomes cheaper on a per-part basis as the number of parts grow. With AM, each part—the first or the last—has the same production cost.

We often see a break-even point for the two manufacturing methods at about 8,000-9,000 units. However, sometimes the number is much higher. For example, there are circumstances where AM is less expensive than injection molding for up to 30,000 parts. We can see that ramping up to hundreds of thousands of parts.

AM can also introduce urgently needed resiliency into supply chains.

For example, SmileDirectClub uses Multi Jet Fusion to produce millions of the molds to make its aligners, which is enough to keep up with its current production of 40,000-50,000 aligners a day. Now is the time for injection molders to capture higher margins, better serve their customers with fast-to-market products and support local manufacturing while maintaining their global reach.

AM can also introduce urgently needed resiliency into supply chains. With AM, it’s relatively simple to design a part in the U.S. and then produce it in, say, the U.K., where it’s needed. Then, just email the file to a printing facility in the U.K. Electrons are cheap to ship; molds are not. This advantage has benefits on several fronts. For example, those digital files incur no tariffs, unlike a finished product that travels internationally.

Distributed local manufacturing enabled by additive has been crucial during the pandemic—for example, all of the face shields for medical workers. One Thursday night in 2020, early in the pandemic, we got a call saying there was a shortage of face shields and asking if we could produce them quickly. By Monday morning, we printed and assembled the first face shield design. In two weeks, we had the design certified and shared with hundreds of different digital manufacturers across the globe. That sums up the excitement of AM.

The pandemic is just one proving ground for the new supply chain paradigms our world is rapidly moving toward—where customization and resiliency are leading differentiators. The time is now, and there is no doubt that manufacturers who can combine the efficiencies of injection molding with the transformative design and supply chain freedoms of AM will become the leaders in plastic parts production.

Related Content

Maintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

Read MoreAdvantages and Disadvantages of Copper and Graphite Electrodes

Both copper and graphite provide approximately the same end result, so it is important for a shop to consider the advantages and disadvantages of each material in order to discover what would work best in their shop floor environment.

Read MoreIt Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

Read MoreTreatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

Read MoreRead Next

How to Improve Mold Venting with Metal Additive Manufacturing

Patented 3D-printed mold insert design rapidly evacuates gases while preventing plastic flash-through, eliminates costly maintenance and need for press-side temperature-control units.

Read MoreAdditive Manufacturing Technology Roundup

MMT received a unique variety of AM-focused products that can be utilized by moldmakers, from software and tooling, to 3D printers and 3D-printed mold components.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.jpg;maxWidth=300;quality=90)