Using Simulation Software to Tackle Complex Moldmaking Challenges

A look at trends and challenges facing moldmakers that have driven software enhancements, and considerations for simulation software selection.

As machine tools and mold designs become more complex, part program verification using CNC machine simulation becomes an essential tool for ensuring that the moldmaker’s NC programs machine the mold correctly the first time. Skipping the verification step creates costly production delays, which cause the machine tool to wait idle while the NC program errors are corrected.

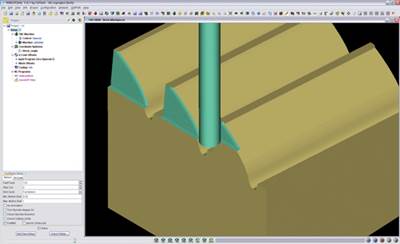

To be truly effective, CNC machine simulation software must interactively simulate and display the material removal process of a NC program. NC programmers use software to verify the quality and accuracy of their NC programs while 3-D simulation of the CNC machine checks for collisions. However, the goal of simulation is not simply a collision-free and efficient NC program. The first and most important goal is a NC program that produces the correct workpiece.

Reducing the time required for moldmakers to easily develop, analyze, inspect and document the CNC programming process is an additional simulation software objective. Moldmakers should look for software that creates an in-process model can help them determine whether or not the NC program will make a correct mold. For example, many NC programs use circular interpolation. In order to measure the cylinder as an as-machined feature, the software must emulate the circle motion. Most internal simulations—the simulation included with most CAM packages—do not emulate circle motion, but instead divide the circle motion into a series of linear motions approximating the cylinder. These segments are not measurable as a cylinder.

Simulation software development is often driven by the evolutionary changes in manufacturing technology: new CAD/CAM software features; new machines and tooling; new machining techniques and processes; and a moldmaker’s need to implement and improve on these changes. Following are some trends and challenges facing moldmakers today that have resulted in ongoing software enhancements.

Trends and Challenges: More and more moldmakers need to simulate specialized processes and complex machines. When a specialized process reduces production time or increases reliability, it becomes adopted by more companies. If a software developer supports simulating these special processes early, it instantly supports the next customers who adopt them. For example, years ago it was rare to see a NC program utilizing local part coordinate transformations and tool axis vector programming. Now it is fairly common. By supporting these features when they were initially adopted, others have benefited.

Adoption of complex machines is similar. Not many years ago, 5-axis machines were rarely used by moldmakers. Today, more multi-axis milling machining centers are being used for moldmaking previously done using simple 3-axis milling machines. This trend has been fueled by a significant decrease in the price of multi-axis machining centers over the past several years. Even small and mid-sized mold shops that previously would not have considered buying a 5-axis milling machine, now have to learn how to se tup and program these machines; accurate 5-axis NC program verification and machine simulation becomes a mandatory tool.

While moldmakers benefit from significantly fewer required set ups, the chance for collisions among machine components, tools and parts is very high. Complex machine tools typically involve many moving parts—often moving simultaneously, in a small space, at very high speeds, very close to an expensive workpiece. Additionally, the machine parts themselves are expensive and sometimes have a long leadtime if they need to be replaced due to a collision. Wrecking a high-speed spindle can ruin more than just a moldmakers day, but the effort required to manually validate a NC program that drives a highly complex machine is impractical. Significant software enhancements were necessary to support these complex machines during their early introduction into the industry.

No one wants to spend time simulating a machining process. However simulation is a necessary engineering step because of today’s complex and fast-paced manufacturing environment. The faster the simulation can return results, the better. The overall simulation time is an important consideration in every software purchase. Simulation software must be constantly evaluated, and the software developer must regularly invent and implement new algorithms to improve speed.

Additionally, no one wants to spend time setting up a simulation session. To further simplify setting up a session, tool libraries should be created by importing CAD solid models of inserts and holders. This makes it simple to specify which parts of the CAD model file correspond with which holders, cutters or inserts.

As both the manufacturing and computer industries have evolved throughout the past 23 years, CNC simulation and verification software has been continually updated. However, as more features are added, added complexity is inevitable. Some developers has ensured that the design and user interface is regularly reviewed and refreshed, focusing on how customers use the software and how it can better fit a modern mold manufacturing environment.

In some newer software releases, the user interface has a more natural sequence to common user actions. Using a top-down flow through a graphical tree layout, context sensitive choices appear as the user moves along the NC program simulation process. Setting up a new project and running a simulation session becomes very intuitive.

Additionally, developers have spent thousands of hours optimizing simulation methods, thereby creating the fastest, most efficient motion simulation to date. As a result, the moldmaker can spend less time setting up and running simulations, and more time making molds.

Related Content

How to Select a Mold Temperature Controller

White paper shares how cooling channel analysis, which collects maximum pressure drop, total flow rate and heat dissipation, eases the performance evaluation of mold temperature controllers.

Read MoreFour Micro Tooling Considerations

Issues involving gating, ejection, mold splits and direction of pull are of special concern when it comes to micro tooling.

Read MoreHow to Manage Wall Thickness Changes in Your Mold Design

To ensure even filling and cooling, consider wall section transitions, corners and fillets, ribs and bosses, lip and rim designs and CAE flow simulation software.

Read MoreWhat Is Scientific Maintenance? Part 1

Part one of this three-part series explains how to create a scientific maintenance plan based on a toolroom’s current data collection and usage.

Read MoreRead Next

Machine Verification Software Slashes Leadtimes, Builds Confidence

When Tri-Mack Plastics Manufacturing Corp. (Bristol, RI)—a manufacturer of high-performance components for critical applications primarily for the aerospace industry—was looking for the least expensive way to cut leadtimes, verify cutter paths, and virtually inspect their cut parts, all without sacrificing quality, the company turned to CGTech/Vericut software (Irvine, CA) to accomplish these goals.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More