Using DSSP to Reinvent Footwear Manufacturing

Timberland is using digital shape sampling and processing (DSSP) technology from Geomagic for greater footwear customization, faster time-to-market, more consistent quality, and manufacturing with considerably less waste.

Timberland is a cultural icon, a dream brand. The nickname “Timbs” is name-checked on dozens of hip-hop lyrics, and one of the genre’s best-selling producers, Timbaland, is named after the company’s footwear. On the corporate side, Timberland’s commitment to social responsibility is respected and emulated worldwide.

Amid all this, it’s easy to forget that Timberland also is a manufacturing innovator. In the 1960s, the company introduced injection molding to the footwear industry, fusing soles to leather uppers without stitching. The result: one of the first truly waterproof boots. Over the last decade, the Timberland product line has expanded from rough-and-ready outdoor boots to a full line of footwear and apparel for men, women and children.

The latest innovation salvo from the nearly 90-year-old company is taking place behind the scenes: Timberland is using digital shape sampling and processing (DSSP) technology from Geomagic for greater footwear customization, faster time-to-market, more consistent quality and manufacturing with considerably less waste.

It might not be the stuff that inspires rappers’ rhymes, but it could well mark a turning point in how shoes are designed and manufactured in a global enterprise, to a worldwide customer base.

Lasts Different from the Past

Since ancient times, shoes have been designed and made according to lasts, a mold that approximates the form of the human foot within various styles of shoes. Traditionally these were made of wood, but now they are generally made from blocks of plastic milled by CNC machines.

Timberland currently produces between 100 and 120 lasts per year across its major product lines: Outdoor Performance, Authentic Youth, Industrial-PRO and Casual Gear. Until two years ago, all lasts were created and modified by hand, then shipped to the company’s manufacturing facility in the Dominican Republic, or to Asian partners in Thailand, Vietnam and China. Incorrect and outdated lasts were thrown away, unless they were newer ones made with polypropylene, which can be recycled.

With the new DSSP process, hand-made lasts represent only 10 percent of lasts used for design and manufacturing. Reworks, a frequent occurrence with hand-made lasts, have been reduced by 75 percent, according to Terry Anderson, a Timberland last engineer.

“We can now visualize a last before it is used to make a shoe, and if needed, create a rapid physical prototype within three-to-four hours for a design and engineering review,” says Anderson. “Material waste has been drastically reduced, and we’ve eliminated the chemical fillers we used for sculpting new shapes.”

Hand Craft Meets Digital

Timberland has made the transition to its new last production process in just over two years by implementing DSSP, a collection of technology components that enables users to quickly create accurate digital models of complex physical objects.

DSSP is used by manufacturers worldwide to capture a part with a 3-D scanner, reconstruct the measurement data (point clouds) into highly accurate polygon or NURBS surfaces, and use the resulting digital model for applications such as product design, tool and mold design and verification, customized manufacturing, recreating legacy parts, engineering analysis, digital archiving and computer-aided inspection.

At Timberland, the process of creating a completely new last starts the way it has for decades: a concept is specified by the product design team, usually based on an existing last that has worked well. An in-house last engineer creates the first iteration by hand.

“The engineer cuts, fills and adjusts the shape, keeping in mind the balance of key fit points and design aesthetics,” says Toby Ringdahl, CAD manager for global footwear development at Timberland.

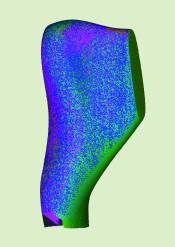

Once the initial form has been developed, the last is scanned with a Konica-Minolta Vivid 9i laser scanner. The scanner captures the shape of the last as thousands of 3-D points, with resolution up to + 0.008 millimeters. A turntable controlled by Geomagic software helps automate and speed up the process. Multiple scans are made to capture the complex curves of the last. For most lasts, scanning takes about 20 minutes.

From Physical to Digital

Point-cloud data from the scanner is brought into Geomagic Studio digital reconstruction software, which automatically aligns the multiple scans. A module called Wrap eliminates time-consuming surface reconstruction work by mathematically wrapping a polygonal surface around the point-cloud data.

Geomagic Studio provides intelligent data filtering to preserve features and minimize visual noise from the 3-D model. Timberland uses automated features in the software to quickly fill holes and remove blemishes while maintaining surface curvature, and to reconstruct sharp or creased edges lost during scanning.

The Geomagic process typically takes around 20 minutes. From scanning to digital reconstruction, a precise digital replica of a last is produced in about an hour. A more complex object, such as an entire shoe with many more features and details, can take three or four hours, according to Doug Maughan, a 3-D technology specialist in Timberland’s global footwear development department.

“Geomagic software provides a lot of features that automate and speed up the process,” says Maughan. “Two examples are ‘select by edge length’ and ‘select by curvature’. Select by edge length is extremely valuable in eliminating shadow surfaces created during scanning, where a surface is formed across what should be a gap; the software automatically identifies these because of longer edge lengths. Selecting and deleting these surfaces manually can be very time consuming. In a similar manner, select by curvature cuts down the amount of time needed in finding and eliminating areas of high curvature from smoothing operations.”

Endless Possibilities

Once basic lasts are captured in digital form, the design, prototyping and manufacturing possibilities—and benefits—are seemingly endless.

Ringdahl says the biggest time savings come from being able to modify lasts quickly, and by digitally transferring 3-D last files to overseas factories instead of shipping physical products.

With DSSP, modified versions of existing or historical lasts can be created based on models from Timberland’s quickly growing digital archive, which now contains more than 500 designs.

Design conceptualization can be done in minutes by making changes to the 3-D model. In cases where a physical prototype is needed, Timberland sends the Geomagic data to a Z Corp. rapid prototyping system, which can produce a realistic physical model for design and engineering review in three or four hours.

Timberland is finding that DSSP is a vehicle for exploring the type of eclectic designs and customization that defines brands in today’s consumer market.

“We can physically replicate three or four new styles a day,” says Anderson. “With our old way of developing lasts it would take up to two weeks to produce a single physical prototype. With the digital model, we can look at and quickly explore many more design options and aesthetics, such as top-down view, center silhouette profile, bottom shape, toe character, heel height, toe spring, footbed/chassis thickness, and boot- or low-cut profiles.”

Anderson says 3-D digital data exchange with manufacturers improves overall quality of the final product.

“Our goal is to standardize fitting and grading with our manufacturers,” he says. “With DSSP, we have a direct link to those manufacturers. This leaves less chance for error, as we are sending the exact data directly to them.”

Adds Ringdahl, “Our new lasts are often based on proven lasts that we know fit well and are suitable for manufacturing. DSSP and rapid prototyping has helped us create a consistent fit and feel to our footwear. The heel area that is so critical for fit, for example, can be maintained while the forefoot shape is modified to address a fashion or specific end use.”

At the back end of the process is archiving, formerly a process involving a lot of manual labor and physical space to store and retrieve hundreds of historical lasts. Now, Timberland transfers the Geomagic 3-D models of lasts to an electronic library managed using 3Shape software. 3Shape provides a structured database, search and browsing functions, and an archival display of all relevant information.

“We’ve greatly improved access and management of historical data,” says Ringdahl. “We now have a searchable database with version control and better tracking of metadata—such as development notes, measurements and other information necessary to ensure design and manufacturing accuracy.”

The ramifications of DSSP at Timberland even extend to extracting information needed to analyze import and export duties or tariffs.

“We use the Konica-Minolta scanner and Geomagic software to perform what is called a 3-D duty analysis of our shoes,” says Maughan. “We scan an assembled shoe upper and then delete areas that don’t count toward the duty or tariff. After further scan processing in Geomagic, we select the section of the shoe containing a certain material, and use the software to measure the surface area. This enables us to compare the material content of the shoes, such as leather versus man-made materials, to pre-determine duties or tariffs.”

Virtual Shoes and Beyond

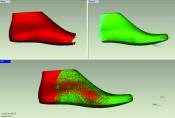

If Ringdahl's vision is any indication, DSSP is still in its infancy at Timberland. The company plans to soon use Geomagic Qualify computer-aided inspection software for geometry and shape comparison among different type of shoes. Geomagic software also is likely to be used to create photorealistic “virtual shoes” that could be reviewed on screen by designers and manufacturers at any location in any part of the world.

Ringdahl thinks DSSP has the potential of helping Timberland deliver more customized styles to the market in much less time. He cites the woman’s Casual Gear line as a hypothetical example:

“Most of our competitors in the woman’s casual market introduce new products four to eight times a year, while we typically design and develop new products twice a year. Currently, something like 150 woman’s casual styles are produced every six months, and the time needed for production and shipping is fairly fixed.

“But if we effectively employed technology tools such as DSSP and rapid prototyping to reduce the design and development segment of the cycle, the possibility exists to produce 75 to 90 styles every three months. If we could present fresh new woman’s casual products four times a year, it could mean a 25 percent increase in revenue, since buyers will have additional opportunities to place new and original Timberland products in their stores.”

Beyond Black and Brown

Timberland is one of the companies blazing a new path toward mass customization, where a wide variety of individualistic styles can be made and brought to market at the same cost as traditional mass production of a few basic styles.

“Timberland is an iconic brand that is using DSSP to fulfill the vision of mass customization,” says Ping Fu, president and CEO of Geomagic. “It’s not a black-and-brown shoe world anymore. Timberland is blending technology and design to make authentic products tailored to specific tastes and different local cultures around the world. That’s the future of manufacturing in the 21st century.”

Related Content

Leading Mold Manufacturers Share Best Practices for Improving Efficiency

Precise Tooling Solutions, X-Cell Tool and Mold, M&M Tool and Mold, Ameritech Die & Mold, and Cavalier Tool & Manufacturing, sit down for a fast-paced Q&A focused on strategies for improving efficiencies across their operations.

Read MoreHow to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

Read MoreOEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

Read MoreMaking Quick and Easy Kaizen Work for Your Shop

Within each person is unlimited creative potential to improve shop operations.

Read MoreRead Next

DSSP: The Catalyst for a New Revolution

One CAD short- coming—a frequent disconnect between the final manufactured product and the idealized CAD model—is being addressed with digital shape sampling and processing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.jpg;maxWidth=300;quality=90)