To close out 2020 we have compiled a list of the top products that you, our readers, have checked out the most this past year.

Note that, based on Google Analytics, these products with 2020 publish dates were pulled from between Jan. 1, 2020 and Nov. 4, 2020, and identified by their number of unique page views, which represents the number of times the specified page was viewed at least once.

Enjoy some of the favorites below, or see what you might have missed! Don't forget to look for some of these items in our December print issue or digital edition.

Michmar Engineering announces the EZ Slider, which eliminates the need for traditional slide and lifter components. This product is said to simplify 2D machining by readjusting travel without the need to remanufacture horn pins, slide travel stops or replace slide locks. The EZ Slider comes in standard 5 degree increments of deceleration up to 35 degrees eliminating the need for costly mechanical or hydraulic drivers.

A visual rundown of this product can be found in the original product posting above. It even solved Venture Global Engineering's (VGE) desire for an easier way to install slides and other side-parting actions in space-limited areas of tool.

The DMS dynamic SGD mold venting valve allows air and resin gases to dissipate via a venting channel, ensuring the production of quality parts.

“Dynamic” venting valves — as offered by the SGD mold venting valve product — act as alternative solutions which can be either external or internal to the cavity, and are designed to allow the air and resin gases to rapidly leave the cavity via a venting channel.

Hasco’s positive locking cylinder Z2302, is for high-temperature applications in compression and injection molding tools up to 180°C. The cylinder has optimized gaskets and is easy to mount, and the integrated positive locking means there is no need for a locking device on the mold.

Meusburger’s E 1770 is a solution developed to guarantee minimum effort for customers and to avoid the “diesel effect” during the injection process, a venting problem that occurs when the air cannot escape fast enough via mold parting surfaces. The product guarantees a fast and targeted ventilation of the cavity via the ejector pin.

Molder’s World Inc. has developed and made available its next-generation Vortex, a self-venting mold steel specifically designed for injection molding applications. This was specifically in response to the discontinuation of Porcerax II, and the company’s realization that they were not only able to replace it, but to improve on the qualities the industry had come to rely on.

Though primarily used for speaker grill insert, interior automotive and medical applications across the globe, Vortex can be used in nearly every molding application where gas buildup is problematic.

Constellium offers its Alumold series of high-strength aluminum. The material is specifically designed for toolmaking and two grades in particular stand out: one to provide the highest possible strength and hardness available and the other one to operate at high molding temperatures (up to 200°C).

These new alloy grades were recently used by DRS Industrial, enabling it to build better molds faster and at a lower cost, improving molder productivity.

Gesswein introduces the Everes desktop 3D printers, which use the latest in digital light processing technology. An intuitive user interface and self-calibration enables users to take designs from ideation to creation. Designed are printed layer by layer, from 25 to 200 micron depending upon which Sisma refillable resin used. Zero tilting technology (ZTT) ensures that parts are not pulled away from the vat when printing, avoiding suction between the object and the print bed.

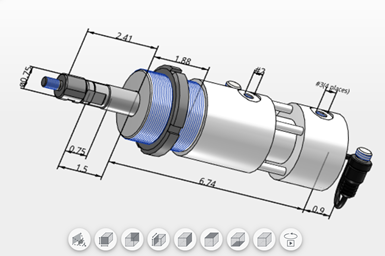

PFA, Inc. announces the release of the 70 series “mini” hydraulic preloading and locking cylinder as part of the Kor-Lok side-action system product line. Providing tremendous preloading capacity in a small cylinder and locking in the preload are the product's primary advantages.

The mini’s 8,000 lbs of preload activates force in a new narrow format, enabling multiple small cores to nest together and time independently.

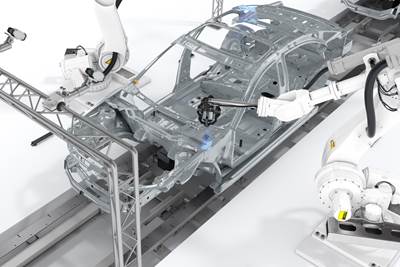

DME’s latest servo unscrewing device “multi” (SAM) technology from its Servomold brand, is said to meet the demands of high-performance injection molds with the unscrewing function.

This system has the ability to rotate the core itself 180º for two-shot applications, unscrew then eject after the second shot. With 1x to 96x unscrewing concepts, SAM is for all internal type threaded applications. It is also cleanroom-suitable, and maintains a compact design.

AddiFab has been working on freeform injection molding (FIM), a unique blend of AM and injection molding, and now the company is ready to step into the spotlight.

The FIM technology is deceptively simple, yet extremely versatile. According to the company, the proprietary platform is used to create injection mold cavities, which are tough enough to process reinforced PEEK and other high-performance materials. They are also dissolvable, which enables injection-molding components that are too complex for conventional tooling.

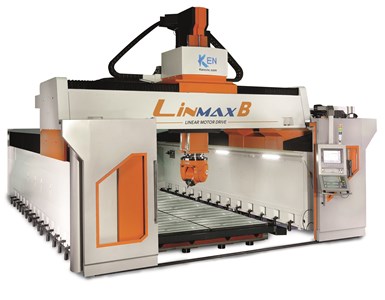

The Linmax B-3040 linear five-axis machining center sold by Dynamic International offers a box in box, symmetrical design to drive at the center of gravity, minimizing crossbeam deformation after long periods of usage.

The machining center provides advanced FEM analysis and design to optimize higher rigidity, response and stability of high speed cutting. The center’s structural design minimizes the environment temperature affection, ensuring high precision during machining, and the Z-axis equipped with four linear guideways enables each side to undertake the same cutting force, enhancing machine lifetime and accuracy.

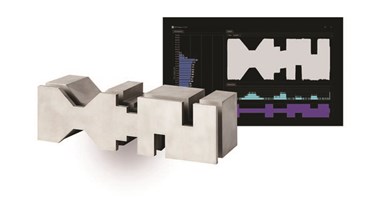

GF Machining Solutions offers Spark Track technology for wire-cutting EDM. Spark Track, powered by the company’s Intelligent Spark Protection System (ISPS) module, prevents wire breakage that occurs when cutting irregularly shaped workpiece features. With Spark Track technology and the ISPS module, wire EDM users gain secure and uninterrupted EDM processing, improved machining efficiency and ease of use for operators.

Based on the spark data gathered, the ISPS analyzes and automatically recognizes shape changes and adapts machining parameters accordingly to prevent wire breakage during roughing.

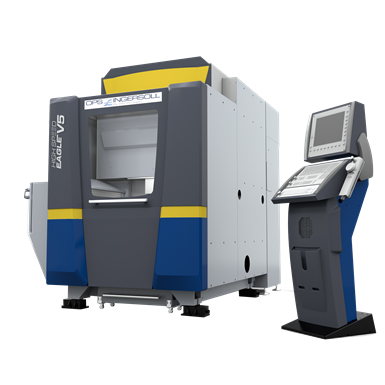

MC Machinery features several of the company’s innovative milling, wire and sinker EDM equipment.

Capable of simultaneous five-axis machining, the OPS Ingersoll Eagle V5 five-axis milling machine, for example, is built for rigidity and fine precision. The machine is built with a 42,000 rpm, integrated spindle, a heavy-duty, roller-type linear glass scales in both the X and Y-axis. It also comes standard with a Heidenhain iTNC-530 control unit mounted on a moveable pedestal for convenient positioning.

Built for general-purpose or intricate milling work, the DV800 CNC milling machine includes a 15,000 rpm direct drive, Big Plus spindle. The machine includes the Mitsubishi M80A Series control with a 15-inch touchscreen with cell phone-like functionality and 135,000 block per minute calculation speed.

Learn more about the EA12S Advance Sinker EDM and MV1200-S Advance M800 wire EDM sinker system in the link above.

Uddeholm launches AM Corrax powder specifically designed with the needs of plastic injection molders in mind. This powder is purposefully made for additive manufacturing with a unique set of properties, making it the ultimate choice for tools where superior corrosion resistance combined with high hardness is needed. Since its launch, the powder has proven itself in plastic extrusion and injection molding applications.

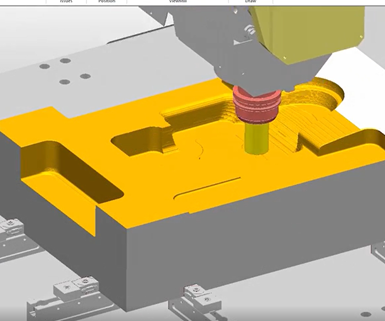

PowerMill five-axis CAM software from Autodesk, Inc. provides expert CNC programming strategies for complex three- and five-axis subtractive, high-rate additive and hybrid machining. Features in the latest software release enable easier three- and five-axis programming, simulation and verification, including accessing a vast library of CNC strategies to reduce programming times with rapid toolpath calculation.