Published

Throwback Thursday: Wish List

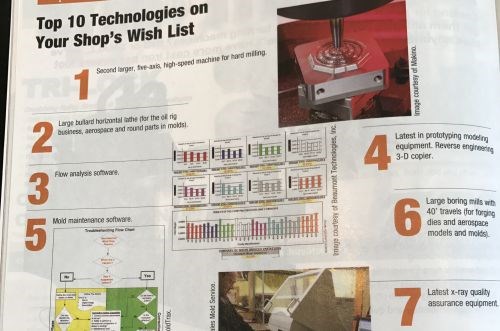

Back in 2008 we asked readers for the top 10 technologies on their shop's wish list. Here they are.

Last month we featured our 2017 Leadtime Leader winners, Graphic Tool of Itasca, Illinois and Concours Mold of Lakeshore, Ontario Canada, both of which have facilities full of tried-and-true equipiment and the latest in technology. In an effort to do a little comparison of the technology used by our 2008 Leadtime Leader winners (StackTeck, Extreme and Commercial Tool & Die), I discovered the results of a poll we conducted with our readers, asking them for their shop's top 10 wish-list technologies.

Keep in mind that the state of the economy almost 10 years ago was a bit sluggish, although future expectations remained positive, as it was projected that total demand for most plastic products, as well as new molds and tooling, would gradually start to increase that fall.

At any rate, the list is interesting. What does your wish list look like today?

1. Second larger, five-axis, high-speed machine for hard milling.

2. Large bullard horizontal lathe (for the oil rig business, aerospace and round parts in molds).

3. Flow analysis software.

4. Latest in prototyping modeling equipment. Reverse engineering 3-D copier.

5. Mold maintenance software.

6. Large boring mills with 40’ travels (for forging dies and aerospace models and molds).

7. Latest x-ray quality assurance equipment.

8. Five-axis gun drill for small components that will allow you to drill on an angle instead of putting the block on an angle.

9. Product data management (PDM) software. A job tracking system that fits your work flow.

10. A new sinker EDM and CNC toolroom lathe. Horizontal machining center with turntable.