The Marriage of Moldmaking and DMLS

Three factors influenced this molder's decision to use direct metal laser sintering: a decrease in waste, faster mold production and design flexibility.

Harbec's primary business is plastics injection molding, but according to Keith Schneider, Harbec's DMLS expert, the company invested in direct metal laser sintering because the company's owner was interested in building mold cavities and cores using this technology.

Three factors inherent in the technology influenced the decision: a decrease in waste as compared with subtractive CNC processes, faster production of molds, and the design flexibility that sintering provides tool designer/mold makers for conformal cooling strategies.

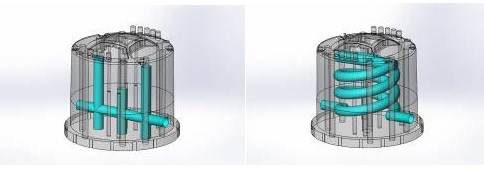

Because DMLS can create extremely complex geometries, laser-sintered cooling channels are able to closely follow the contours of the mold’s cavity surfaces (see images). This increases the surface area of the channels and improves the efficiencies of the cooling process. It’s a simple principle: When channels conform closely to the product, the part cures more evenly and the cure time is reduced.

These CAD-based images show a conventional machined steel core with straight channels (left) and a conformally cooled core with spiral cooling channels (right), which was manufactured using DMLS™. In a test performed by Harbec of different curing times and part shrinkage after ejection from the mold, it was shown that the part was able to be cured more quickly using the conformal curing core while achieving dimensions that more accurately met specifications. In injection molding operations running hundreds of thousands of parts annually, if cure times can be reduced, even by seconds, cycle times follow, allowing for faster production turnaround times and reduced cost.

“The bulk of the cost of injection molding comes from the time parts spend cooling in the mold,” says Schneider. “DMLS has allowed us to dramatically reduce cycle times and improve the economics of part manufacture for our customers."

Related Content

-

How Hybrid Tooling Accelerates Product Development, Sustainability for PepsiCo

The consumer products giant used to wait weeks and spend thousands on each iteration of a prototype blow mold. Now, new blow molds are available in days and cost just a few hundred dollars.

-

Mold Builder Uses Metal 3D Printing to Bridge Medical Product Development to Production

Westminster Tool uses metal additive manufacturing for medical device OEM, taking lessons learned from R&D in the prototype mold phase to full-scale production molding in a fraction of the time.

-

MMT Chats: California Mold Builder Discusses the Difficulties with Silicone Molding and the Power of the Magic 8 Ball

MoldMaking Technology Editorial Director Christina Fuges sits down with M.R. Mold President and Owner, Rick Finnie, to discuss how he began his moldmaking career, M.R. Mold's LSR Education, and the struggles of working with silicone. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

.jpg;maxWidth=300;quality=90)