Tailored Tool Paths Translate into Savings

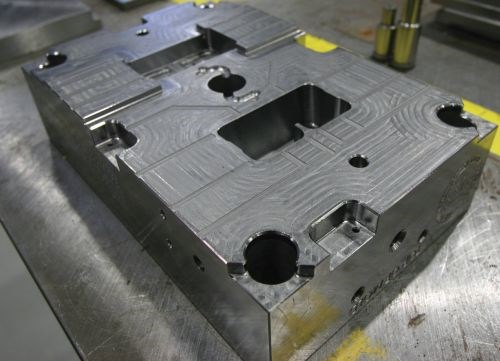

The implementation of CAD/CAM with tool paths tailored to high-speed machining and hard-metal cutting, helped this precision moldmaker dramatically increase its toolpath efficiency.

Rockford, Michigan’s Byrne Tool + Design (BTD) has built its mold manufacturing business by focusing on precision, value and partnerships. It credits its innovative manufacturing approach, fast turnaround time and longstanding reputation for quality to the purchase and implementation of Visi manufacturing software for the tool and mold industry. The speed and convenience of Visi combined with BTD’s more than 20 plastic injection molding machines allow the company to quote production molds to fit a variety of manufacturing needs.

For 40 years, BTD has been manufacturing plastic injection molds and components for customers in the medical, office furniture, nautical and automotive industries who specialize in manufacturing extremely precise parts. BTD provides service and support for the entire lifecycle of each mold it manufactures, with the intention of yielding a rapid, cost-effective response when a customer’s operation goes down. This approach has become the cornerstone of the company’s growing customer base, and it says employing the right software technology has been key.

Finding the Right Fit

Andrew Baker, BTD’s operations manager, says the company determined 10 years ago that switching from a surface-based to a solids-based CAD system would be the most efficient method for staying ahead of the manufacturing curve. BTD had been experiencing difficulties with file translation issues, and this was holding up a majority of its work. The production process was continually being hampered by bad tool paths. This and other difficulties pushed the company to search for a complete software solution to fit all of its needs.

BTD wanted a single solution that offered both CAD and CAM functionalities, and it eventually decided on Vero Software’s Visi solution, available through master distributor TST Tooling Software Technology of Clarkston, Michigan.

BTD’s selection of Visi was based on several key factors, including tool paths inside the software that are tailored to high-speed machining and hard-metal cutting. Visi uses smooth corners, stopovers and arc fitting to minimize sudden direction changes and therefore ease high-speed machine tool programming. This also eliminates tool retraction, helps maintain a constant tool load and optimizes NC code. By implementing Visi, BTD says it was able to not only speed the design time and increase its accuracy, but also create a paperless environment on the shop floor.

“It was a seamless transition,” Baker says. “TST assisted with the software installation, during which our entire manufacturing process went uninterrupted.” And perhaps more importantly, BTD was able to design a mold in Visi exactly as it would appear when the mold shipped. Potentially costly mistakes were caught and corrected before production without causing a hit to the company’s bottom line. In addition, training shop employees on the software was simple, Baker says. With the new software, BTD went from experiencing toolpath issues on 80 percent of its jobs to having such problems on only 20 percent of the work.

Adding On

After experiencing such success with Visi, BTD decided to also add Visi 3D, which offers benefits including a 3D stepover function that enables programmers to maximize surface finish with the help of toolpath morphing across the component’s surface, regardless of the component’s size or shape. One tool path finishes the entire job while keeping the tool on the surface of the component, minimizing retraction movements and eliminating duplicate cutter paths.

In addition, the software allows the company to share files with its customers, improving communication. With an extensive range of CAD interfaces and translators, Visi works directly with most CAD software and ensures that users can work with data from almost any supplier.

“Visi has really helped with translating customer CAD files. Whether they are wireframe, solid-surface, mesh data or a combination, we are able to work with any CAD data to quickly re-model parts for machining,” Baker says.

BTD also has added a Visi viewer to each of its machine stations, allowing the operator to maximize the software’s capabilities, which include changing solid, wireframe and face colors; importing multiple file types; and creating bounding boxes while adding dimensions to plot-view drawings.

“Sharing native files with our customers and collaborative tooling partners has been seamless,” Baker says. “Using the same software allows us to quickly and effectively communicate challenges and changes to the customer without ever leaving the shop. Our move to Visi has convinced many of our customers to purchase the software.”

The software switch also has contributed to BTD’s 15-percent annual growth rate, which has positioned the company to remodel its collaborative Design Center offices to create a cleaner and more streamlined work environment. This includes adding 6,400 square feet of manufacturing space to meet the demands of increasing production.

This growth also has prompted the hire of new designers, moldmakers and operators, as well as investment in new machine technology. BTD recently purchased a Makino horizontal milling machine along with a new fixture designer to focus on producing fixtures for Byrne Electrical—BTD’s sister company that specializes in power and data technologies—which supports BTD’s growing manufacturing department.

Sustaining Growth Levels

According to Baker, all of these im-provements, along with TST’s support, provided BTD with the tools necessary for continued growth. “If a company has a great product and terrible service, the product is worthless,” he concludes. “Because of Visi software and TST’s technical support, we have been able to sustain a level of growth that would not have been possible

otherwise.”

Related Content

Integrated CAD/CAM Streamlines Electrode Manufacture, Improves Quality

A focus on electrode design and automation helps toolroom improve efficiency, reduce tooling costs and deliver higher quality products.

Read MoreHow to Harness 3D Scanning for Mold Tool Repairs

3D scanning supports the repair of molds with no history, drawings or design files.

Read MoreOEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

Read MoreThe Trifecta of Competitive Toolmaking

Process, technology and people form the foundations of the business philosophy in place at Eifel Mold & Engineering.

Read MoreRead Next

Successful, Profitable Mold Design

What to consider when searching for an all-in-one mold design solution.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

.jpg;maxWidth=300;quality=90)