Refined Product Designs Lessen Mold Rework

The often overlooked benefit to additive fabrication: multiple iterations.

The amazing growth of rapid prototyping (or additive fabrication as it is now being called) over the past decade is directly attributable to the industry’s effective delivery of the benefits the technology promises. Newcomers and veterans alike quickly become familiar with the catch words that describe these benefits. Phrases like “art to part”, “shortened leadtimes” and “closer to the market” make initial investment easier to justify and allow managers to envision significant savings of time and expense in creating new products.

The additive fabrication industry recognizes its biggest sales drivers are “speed” and “money” and capitalizes on these with advertisements, sales pitches and case studies showing how more speed and less money will give your company a competitive advantage in the marketplace. Indeed, most companies adopting additive fabrication technologies are seeing these promises come true.

There is one company however realizing a different, seldom-hyped benefit to additive fabrication that is easily overlooked in the pursuit of faster and cheaper. The company is adidas and the benefit is multiple iterations.

Digital Transformation

Fifteen years ago, the standard timeline to bringing a completely new athletic footwear product to market was 16 to 18 months. The typical process at adidas back then was completely analog—involving hand-drawn design sketches; models carved from wood, Renshape and Bondo; mechanical drawings drafted in pencil; molds cut from blocks of steel using paper templates and confirmation meetings requiring a great deal of travel. It was generally accepted that this process should take 16 to 18 months to complete—thus dictating the time-to-market for any new project.

About 10 years ago the process to create new products began to go through a major transformation as digital technologies like 3-D modeling and additive fabrication became more affordable. Constructed from the benefits promised by digital tools, adidas initiated a plan for the implementation of 3-D modeling and additive fabrication to streamline footwear product creation. The expectation was that these technologies would allow a gradual shortening of the time athletic footwear required to be designed and engineered, while simultaneously decreasing the number of discarded sample molds being created—thus reducing costs.

Fast forward to 2007 and a well-established, completely digital process exists at adidas; however, the current time line to bring a completely new product to market is still 16 to 18 months! According to the now widely recognized mantra of faster and cheaper, one might conclude that adidas’ digital transformation has not generated a measurable savings of time or money at all. What happened? Is there any benefit for adidas from the implementation of 3-D and additive fabrication? Yes, multiple iterations.

Best Products Possible

adidas has always prided itself on the superior quality and construction of its footwear products, but craftsmanship alone does not guarantee sales. Success also is determined by aesthetics—looks often govern whether a shoe is a flop or mega hit.

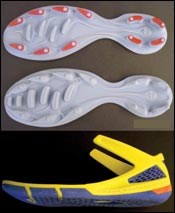

Achieving the right look is not a one-shot operation. It is a process of designing and refining. It is here that adidas has realized the most influential benefit of additive fabrication: the ability to physically represent this process of designing and refining with printed prototypes, known internally as multiple iterations.

Many experts believe there is a direct link between successful consumer product design and the number of iterations a product goes through before finalizing for manufacturing. adidas has found this to be true and uses 3-D modeling and additive fabrication to produce as many model iterations as possible in the pursuit of creating great products.

Back in the analog days, a designer was lucky to have one model to review in the time allotted for creation. Now, it is routine for a designer to review five or six models in the same amount of time. The ability to review multiple prototypes allows designers to progress more naturally through a design—providing many waypoints for improvement. Multiple iterations make for streamlined sampling as fewer design issues have to be addressed in the factory. Overall, the product line is stronger because iteration prototypes are being used to dynamically refine the look of each offering, and a strong product line is good for sales.

The benefits of additive fabrication to adidas are evident: additive fabrication is fast, allowing models to be printed quickly and additive fabrication reduces cost since the product is more finished before being sent for sampling. But faster and cheaper give way to the larger benefit of multiple iterations.

Additive fabrication has not been a driving force for adidas to change the timeline to be “closer to the market”. Instead multiple iterations from additive fabrication are used to make the timeline more effective so adidas’ products are “better to the market”.

Summary

By not focusing solely on the mainstream benefits additive fabrication technologies promise, adidas has been able to discover and exploit an unadvertised hidden advantage additive fabrication provides. Using additive fabrication as a tool to generate multiple iterations has helped to strengthen adidas’ processes and products.

Finally, as we look to the future, the multiple iteration process currently used by adidas also serves as a strong foundation for capitalizing on the more recognized “faster to market” benefit of additive fabrication, if and when it is needed.

Related Content

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MoreRevisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

Read MoreIt Starts With the Part: A Plastic Part Checklist Ensures Good Mold Design

All successful mold build projects start with examining the part to be molded to ensure it is moldable and will meet the customers' production objectives.

Read MoreThe Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MoreRead Next

The Impact of Rapid Prototyping On the Plastics Industry

Examining the level of acceptance and use of additive fabrication technology in the development of injection molded components.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More