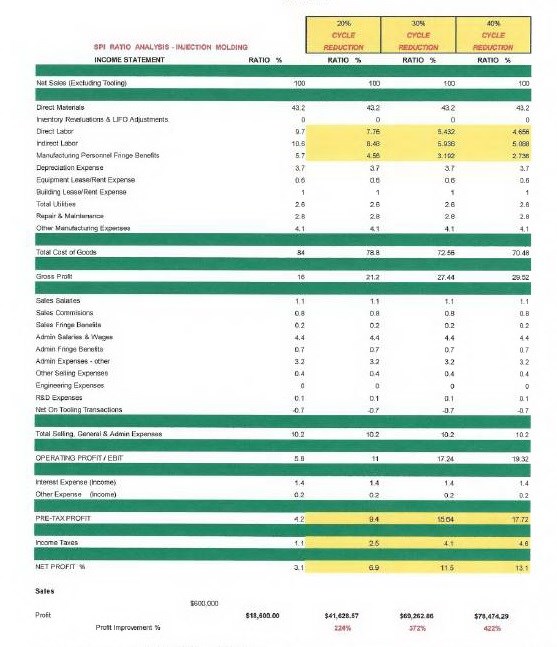

Ratio Analysis: Injection Molding

This ratio analysis published by SPI can be used to show the estimated effect of 20, 30 and 40 percent cycle reduction for just one mold, one press or a whole plant. Just change the Sales dollars at the bottom of the table to change the profit dollars.

According to Bob Beard, P.E., president of Robert A. Beard & Associates Inc,. and a Honored Fellow of SPE, this ratio analysis published by SPI can be used to show the estimated effect of 20, 30 and 40 percent cycle reduction for just one mold, one press, or a whole plant. Just change the Sales dollars at the bottom of the table to change the profit dollars.

To simplify the analysis, consider one mold in the press 100 percent of the time: 6,000

hours/year at $60/press hour. This would generate $600,000/year in Sales. A conventional

mold would generate a profit of $18,600. A conformal mold would generate:

20% cycle reduction = $41,628.57 - a 224% increase

30% cycle reduction = $69,262.86 - a 372% increase

40% cycle reduction = $78,474.29 - a 422% increase

Conformal cooling will decrease rejects (such as warping) because of the mold's uniform cooling; thereore, any reject reduction will fall directly into profits (for example, a 5-percent reject reduction would add an additional 5 percent to profits).

Keep in mind that increases for the cost of the engineering analyses and the incremental cost to manufacture a conformal mold over a conventional mold must be subtracted from the profit.

Related Content

-

How to Manage Wall Thickness Changes in Your Mold Design

To ensure even filling and cooling, consider wall section transitions, corners and fillets, ribs and bosses, lip and rim designs and CAE flow simulation software.

-

MMT Chats: 5 in 5 with Best Tool and Engineering

MoldMaking Technology Editorial Director Christina Fuges reveals 5 best practices for improving efficiencies within shops...in 5 minutes. Our guest is Joe Cherluck, President of Best Tool and Engineering in Clinton Township, Michigan.

-

MMT Chats: Predictable Manufacturing and Incremental Gains Can Transform Moldmaking

MoldMaking Technology Editorial Director Christina Fuges catches up with the president of Eden Tool and Eden Manufacturing, Dave Tomic. We talk about predictable performance in moldmaking and the value of small incremental gains in an organization versus big change via disruptive technology. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.