Packaging and Medical

All signs positive for packaging; medical equipment production poised for growth.

All Signs Positive for Packaging in 2016

Packaging is not an end product in and of itself. So, like a number of other industries, you cannot just grab industrial production data for packaging to see how the industry is performing. However, there are two major industries that drive packaging demand: food and industrial (primarily shipping materials). So by tracking what is happening with the food and beverage, clothing and footwear, and trucking industries, we can get a feel for what is happening in the packaging industry.

Food and beverage spending was virtually flat for most of 2015, but with the strong growth in income, food and beverage spending should see accelerating growth in 2016. In turn, food and beverage spending leads food and beverage production, which is already growing at nearly its fastest rate in eight years. Food packaging seems poised for significant growth in 2016.

Primarily, institutional packaging consists of stretch film, and sheet and tubing, but consumer and industrial product liners and shrink film also are a significant part of institutional packaging. The Bureau of Transportation Services’ freight index is virtually at its all-time high, nearly 20 percent higher than in 2000 and roughly 10 percent higher than in 2007. However, despite this all-time high, the rate of growth was relatively flat in 2014 and even decelerated somewhat in 2015. The growth rate is still strong enough that this is a positive for packaging demand, but the fact that the growth rate is decelerating indicates that institutional packaging is probably a weaker market than food packaging going forward.

Is Medical Equipment Production Poised for Growth?

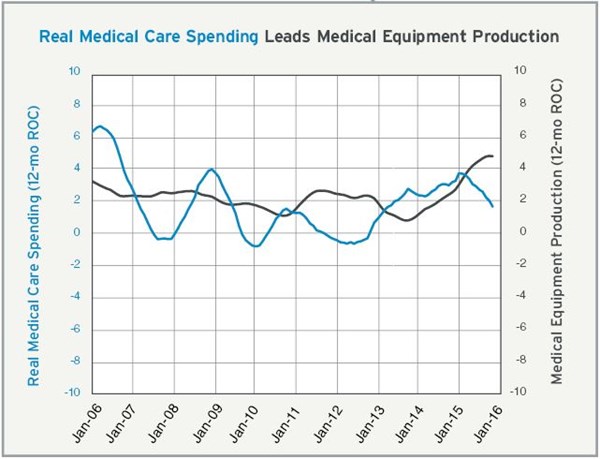

Since the passage of the Affordable Care Act in 2010, the normal cyclical patterns have broken down, making it much more difficult to see the future direction of the medical equipment industry. In the chart at right, note how the regular ups and downs of medical equipment production (the blue line) have become not so regular since 2010. What was once a lag time of six to 12 months between medical care spending and medical equipment production seems to have become a two- to three-year lag time. And the complete market cycle between peak growth rates in production every two years is nonexistent.

If my assumed correlation above is true, then medical equipment production should begin to grow at an accelerating rate sometime in 2016. It has been about two years since the slowest rate of growth in medical care spending. Therefore, we should expect the slowest rate of growth in medical equipment production at any time, since the new lag time between spending and production seems to be two to three years. That is, the blue line on the chart should stop going down and start going up at any time.

Our medical business index is providing some indication that this is happening. The overall index seems to indicate that the medical equipment industry has been contracting at a slower rate since the middle of 2015. The new orders index grew in November and December for the first time since May 2015. The production index grew in November and was flat in December, as it seems to have bottomed back in July 2015. And a number of the other subindices also seem to indicate that the industry has reached a bottom and is beginning to improve.

Related Content

Hammonton Mold, ADOP France Forge Strategic Partnership in Injection Blow Moldmaking

Hammonton Mold Inc., a leading full-service mold shop based in New Jersey specializing in injection blow molds (IBM), proudly announces its official partnership with ADOP France, a prominent IBM mold manufacturer based in Normandy, France.

Read MoreInnovative Mold Building Enhances Packaging Material Efficiency, Elevates Recyclable Design

A manufacturing-focused design and optimized tooling enhance material efficiency in packaging for a new medical instrument.

Read MoreWhat is Driving Mold Lifecycle Management Digitalization?

OEMs are looking to partner with suppliers to share and track data across the supply chain for advanced intervention and process management.

Read MoreHow to Solve Hot Runner Challenges When Molding with Bioresins

A review of the considerations and adaptations required to design hot runners and implement highly productive injection molding operations.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

.JPG;width=70;height=70;mode=crop)