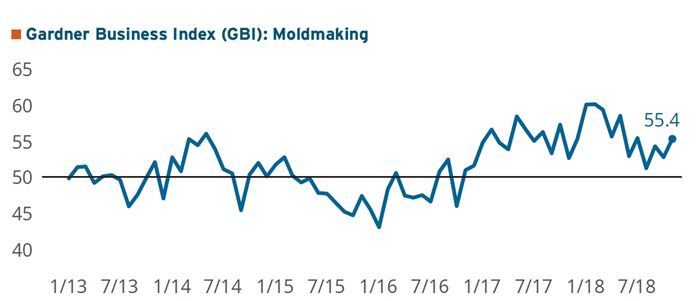

Moldmaking Index Moves Higher On Surprise Rise in New Orders

November 2018 – 55.4

Closing November at 55.4, the Gardner Business Index (GBI): Moldmaking moved higher on a surprise expansion in new orders at a level not experienced since the first quarter of the year. Compared to the same month one year ago, the index is up 4.9 percent. Gardner Intelligence’s review of the underlying data for the month reveals that a very strong expansion in new orders complimented by expansion in supplier deliveries lifted the index higher. The averages-based index was pulled slightly lower by slowing production growth as well as exports, employment and backlogs. No index components contracted during the month.

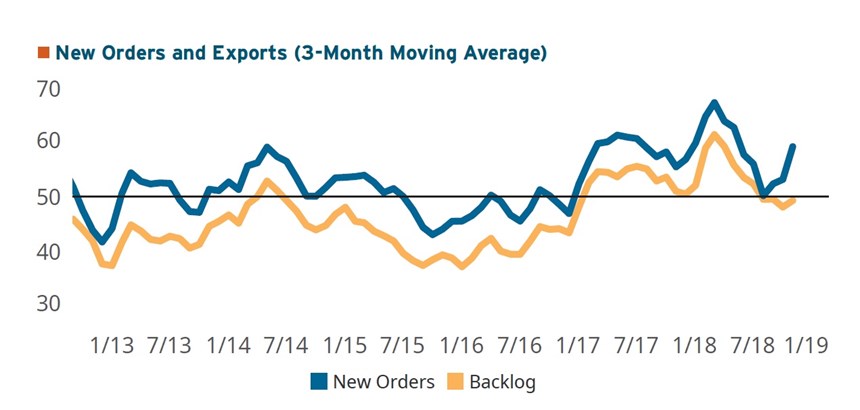

Strength in new orders came from a significant turnaround in exports which expanded at one of the fastest rates since at least 2012. Exports which contribute to the new orders reading, in part suggest that foreign orders played a significant role in the latest new orders reading. In addition, the relatively stronger expansion in new orders relative to production during the month in part explain the strongest expansion in backlog levels in six-months.

About the Author

Michael Guckes is the chief economist for Gardner Intelligence, a division of Gardner Business Media (Cincinnati, Ohio, United States). He has performed economic analysis, modeling and forecasting work for nearly 20 years among a

range of industries. He is available at mguckes@gardnerweb.com.

Related Content

-

OEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

-

The Role of Social Media in Manufacturing

Charles Daniels CFO of Wepco Plastics shares insights on the role of social media in manufacturing, how to improve the “business” side of a small mold shop and continually developing culture.

-

Dynamic Tool Corporation – Creating the Team to Move Moldmaking Into the Future

For 40+ years, Dynamic Tool Corp. has offered precision tooling, emphasizing education, mentoring and innovation. The company is committed to excellence, integrity, safety and customer service, as well as inspiring growth and quality in manufacturing.

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)