MMT Chat: Moldmaker and Steel Supplier Stand and Deliver during Coronavirus Outbreak

This mold manufacturer with the help of its steel supplier delivered a die-cast mold from concept to completion in less than one week for a component that was holding up the production of ventilators.

MMT Chat: Moldmaker and Steel Supplier Stand and Deliver during Coronavirus Outbreak

from concept to die in five days

Bill Berry, President and Owner of Die-Tech & Engineering (DTE) in Wyoming, Michigan, took on a complex die project from in Minneapolis, Minnesota, for a component that is critical to current ventilator production.

Die-Tech and Engineering and Twin Cities Die Casting are just two of the many American manufacturers coming together to help our nation through the COVID-19 crisis.

Die Tech and Twin Cities Die Casting are working to help Ventec, a leading supplier of ventilators, to quickly ramp up production. Die-Tech is currently working on tooling for 10 more parts.

While quoting the job on Friday, March 20, 2020, Berry was already arranging to get the steel for the die. It was delivered overnight and in production by 2 AM Saturday morning (see More to the Story below).

His team continues to work through the night to get the job done--including last-minute mold design changes! The job is completed and delivered as of March 25, 2020. And, it’s important to note that a job of this scope is normally 8 weeks or more. Berry believes that the combined creativity and innovation of American manufacturers is pivotal to the quality of life and security we enjoy today.

More to the Story

A Truly Collaborative Effort: Steel Supplier and Toolmaker Go Above and Beyond

Bill Berry called Seth Galentine at Bico Steel that Friday at 10:26PM with final dimensions for material. Two Bico steel workers from 2nd shift stayed beyond their normal stop time of 11:00PM to get the material on our equipment and processed. I joined these guys at the shop and personally delivered the blocks at 2AM,” Galentine says.

Three other Bico steel workers volunteered to come in for Saturday work (once they had the remaining steel dimensions that were needed to start) to complete the other support materials and custom saw cut work for the remainder of the die build. This work was delivered by 5PM on Saturday.

“Two guys from 2nd shift stayed until 2AM and three other guys gave up their entire Saturday to get this done,” Galentine says.

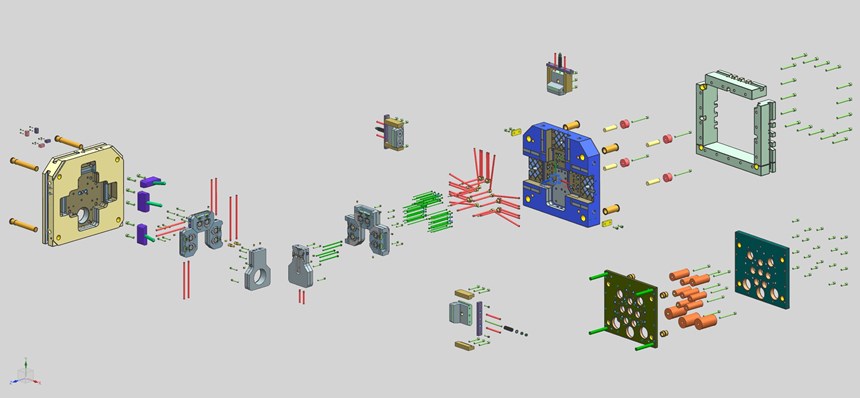

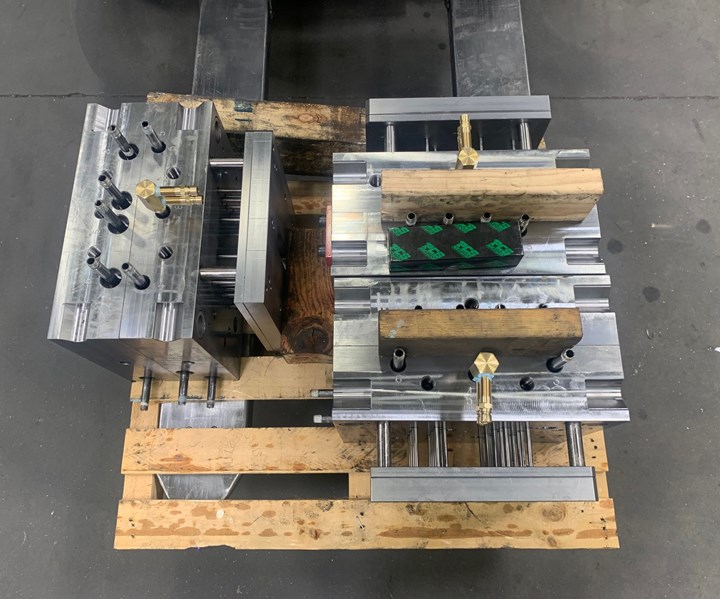

The red arrows in the photo below point to steel that BICO supplied in entirety to Die-Tech and the yellow arrows point to steel that BICO saw cut for Die-Tech. Galentine says Bico has dozens of “Project V” jobs going through the shop right now at breakneck speed – molds and dies.

BICO Steel is a complete, single-source steel plate processor, providing timely solutions to an infinite variety of needs in a wide spectrum of industries.

With continuing success in the plate business, and to more adequately service the tool and die, and plastic mold industries serving the automotive industry, in 1987 The Burger Iron Company opened its second steel plate facility in Grand Rapids, Michigan. In 2001, BICO Michigan moved from its original Grand Rapids, Michigan location and built a new 60,000 sq. ft. facility for its expanding Michigan business. Today, The Burger Iron Company consists of three subsidiaries known as the BICO Steel Service Centers.

Related Content

How to Produce More Accurate Molds and Reduce Rework

Patented micro-milling process for manufacturing steel plate flat and parallel helps mold builders shorten mold build times and increase accuracy.

Read MoreQualified Tool Steel Enhances Thermal Transfer, Long Tool Life

Next Chapter Manufacturing has successfully qualified HTC-45 tool steel, an optimized version of H13, to support better thermal transfer and faster cycle times for molders and die-casters.

Read MoreThree Considerations for Mold Steel Selection

Although a big challenge is selecting the right steel for the right job, steel selection has never been better in regards to quality, price and delivery speed. Here is a simple checklist when selecting your next mold steel.

Read MoreHow to Achieve the Best Mold Finish

A look at factors that impact the polishability of tool steels and recommendations for obtaining a high-gloss finish.

Read MoreRead Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)