MoldMakers’ Christmas Plans, Like Their Molds, Are Wide-Ranging

While their plans, like the molds they build, are rather unique, one element remains constant: Family togetherness and shared traditions.

The holidays are upon us. Hanukah began at sundown on December 12, and Christmas is only a few short days away. It’s amazing how fast this year has passed. In anticipation of this beloved holiday, I reached out to a few moldmakers to ask them how they plan to celebrate this year. While their plans, like the molds they build, are rather unique, one element remains constant: Family togetherness and shared traditions.

For starters, Mike Zacharias, president of Extreme Tool and Engineering in Wakefield, Michigan, says his family will be skiing at Big Sky in Montana. “My younger daughter Kourtney lives in Bozeman and attends Montana State, so my wife and older daughter Kayla will spend Christmas out there and then head to Miami to watch our Wisconsin Badgers take on the Miami Hurricanes in the Orange Bowl!

When I asked Larry Patten, co-owner of Dramco Tool & Die Co. of Grand Island, Nebraska, what his Christmas plans were, he responded by saying, “You mean besides working? It seems that the end of the year is always panic time for customers.” (I’m sure at least a few of MMT’s readers can relate.) He then said, “On a serious note we usually spend Christmas with family. I cook up a nice prime rib. I use various ways to cook it, but it almost always is awesome. Other than that, it's just the normal holiday time of gift giving and spending some time together. This year is different, as my wife Elizabeth and I are planning to take the motorcycle down to Phoenix and spend a week riding in the desert Southwest. We plan on making a circle from Phoenix to San Diego to Desert Hot Springs and back to Phoenix.”

Steve Rotman, president of Ameritech Die and Mold in Mooresville, North Carolina, has an exciting precursor to Christmas festivities. “I got a pretty crazy thing going on December 23. My daughter is pregnant, and we are going to have a ‘reveal party’ at our house. The way that they're going to reveal the gender is by my son shooting fireworks. He’s the only one that knows the true gender of the baby.” (Steve has two granddaughters by his oldest son. This baby is his daughter’s first. He said he will follow up with me after the big reveal party.)

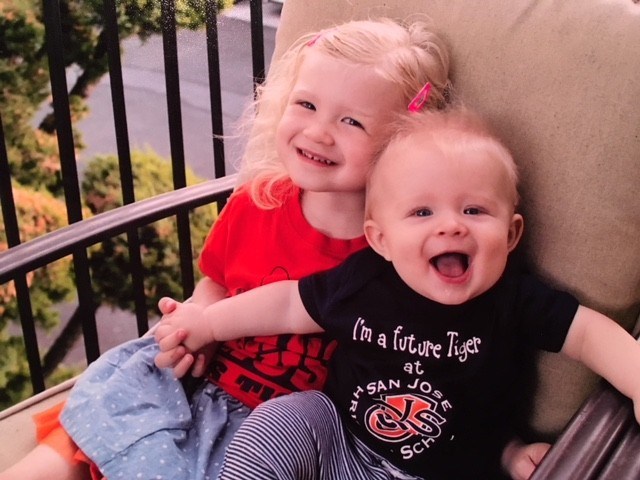

Speaking of little ones, Gabe Meldrum, plant manager at International Mold Corp. in Clinton Township, Michigan, says he’s staying home with his little girls, and working. In September, Gabe and his wife welcomed their second daughter, Beaux Jennifer Meldrum, into the world. He also has an adorable daughter named Ellis Eileen.

Like Gabe, Don Snow, president of CS Tool Engineering in Cedar Springs, Michigan, will enjoy family time and work. “As for me, I will enjoy those days with our family and two grandkids from San Jose, California, and then work the remainder of the time. I’ll be cheering on the employees who are also working to fulfill the promises CS Tool made to our customers: having their tools ready for production. After January 2nd, I may sneak a few days off to wrench on an antique tractor.”

Rich Stueber, operations manager at NyproMold Inc. in Gurnee, Illinois, says traditions are upheld in his family. “This year Christmas will be celebrated much like the years past: Christmas Eve is a visit with family followed by attending our church’s late caroling mass service,” he says. “Christmas Day is big at our house and it starts early in the morning where we all wake up and are surprised by the overnight visit that Santa had made (some traditions just cannot be broken). After opening gifts, we switch rooms to dig deep into our stockings hanging over the fireplace followed by a nice breakfast. This is the calm before the hustle of preparing for more than 20 guests made up of family and friends to arrive. The day is as traditional it gets, from gathering around the tree for an exchange of gifts, holiday music playing with lots of laughter and cheer and then some delicious food. And, if we’re lucky enough to have a football game playing on Christmas Day, it will definitely be on the screen for those who want to watch. Every year great memories are created on Christmas and Debbie and I feel truly blessed and are grateful that we are able to create a meaningful holiday for our families.”

Last, but not least, is Joe Genc, the American Mold Builders Association’s 2017 Mold Maker of The Year, who is very much a “man about town,” visiting family members who live all over. Here’s how his Christmas stacks up: “On Christmas morning I will be leaving my home at about 7 a.m. to travel up to Wisconsin, then back south to Gray's Lake, Illinois, and then down to Glen Ellen, Illinois, and finally I will end up in Bloomingdale, Illinois. I have 22 grandchildren to visit. The good news is that there will probably be very little traffic to slow me down. All four of my stops will have a big party in full swing through the entire day. My last stop is very special since it will be where I dress up as Santa for five little ones...and yes, since I have lost almost 80 pounds, I will need several pillows to fill me out properly. Best Wishes for a HAPPY HOLIDAY and a very Happy. Healthy and Most Prosperous of New Years.”

I couldn't have said it better, Joe.

Enjoy this special slide show and I wish everyone a safe and joyous holiday!

Related Content

OEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

Read MorePredictive Manufacturing Moves Mold Builder into Advanced Medical Component Manufacturing

From a hot rod hobby, medical molds and shop performance to technology extremes, key relationships and a growth strategy, it’s obvious details matter at Eden Tool.

Read MoreThe Role of Social Media in Manufacturing

Charles Daniels CFO of Wepco Plastics shares insights on the role of social media in manufacturing, how to improve the “business” side of a small mold shop and continually developing culture.

Read MoreHow to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

Read MoreRead Next

Reasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.jpg;maxWidth=300;quality=90)