Moldmaker Does Not “Wine” about Precise Undercut and Cross Cavitation Challenges

As a start-up, with limited capital and a new concept, we needed to get into production fast and have the design and tooling right—the first time. “R&D/Leverage proved to be a great partner to work with, and they delivered on all counts.

Stacked Wines LLC (Newport Beach, CA) was conceived by creator and company co-founder Matt Zimmer when he sought a stylish, portable and recyclable packaging solution for informal consumption—whether it be tailgating, a picnic or in a backyard. He teamed up with two fellow MBA students at UC-Irvine to develop a product that offered quality taste, a simple style and—most important—ultra-convenience.

Zimmer, who has a background in plastics and beverages, says he had “one too many drinks from a stale bottle of wine and had an ‘a-ha’ moment about how to solve the problem. So he and his partners put Zimmer’s vision to paper and sketched a practical, easily stored, four-pack of stem-less wine glasses that vertically stacked to form the equivalent of one full 750 ml bottle of wine.

According to Zimmer, each individual serving was to communicate the look and feel of a real wine glass and deliver the durability of plastic. A foil seal would preserve the wine's freshness within each single serving and an overwrap would deliver brand messaging and consumer product information. The compact, stacked format, Zimmer correctly reasoned, would also appeal to shelf-space starved retailers—and would allow 30 percent more cases per truckload than other format options.

His industry connections led him to R&D/Leverage (Lee’s Summit, MO)—a company that provides structural brand development and mold manufacturing for the food, beverage, home, personal care and healthcare industries. The company specializes in full-service plastic product solutions. “We needed expertise into how to commercialize our vision, which led us to R&D,” Zimmer says. “And with so many launches in our industry, time was of the essence, since we compete against standard bottled wines and boxed wines, which are increasingly popular.”

Compressed Time-to-Market

According to R&D/Leverage Project Engineer Jeff Beason, his team developed a product design from the customer's initial product sketches and delivered a manufacturable product design with the snap-together feature that was a key to enhanced consumer and trade functionality. The design was completed and approved in just three weeks using Pro/E by PTC (Needham, MA).

“Stacked Wines had a concept and basic design, which they provided to us,” Beason says. “We were hired to develop the design of what they wanted the bottle shape to be with the finish they needed to accommodate the filling process they chose. It was stated that the stacking feature was a requirement and this snap feature would be a very high value addition if we could make it work. Obviously, the stacking function in and of itself can have issues—such as under-blown areas of the bottle geometry. The stacking was to facilitate using the shrink-wrap sleeve that they wanted to use to market the product.”

Beason explains that the bottles were not just sitting on top of each other, they were nesting. That is why the snap feature was so important. “It involved precise undercuts,” he elaborates. “You can always design special features into a container, but you have to make sure they are functional when the container is molded. It all starts with design goals, and realizing what is actual. In both cases, we were able to create the stacking and the snapping feature on the design.”

Forming the snap feature was a challenge, but the largest challenge was to maintain the form that was created by the mold,” Beason adds. “Oftentimes when a design includes an undercut area, it will not demold or the area will distort to allow it to clear the mold surface.” He adds that the process development R&D used to create the features he wanted is proprietary and part of a “unique” process.

“It all starts with a very accurate design,” Beason notes. “We created shrinkages, etc. based on what the PET is going to do as it molds—and after molding—so those adjustments become part of the complete tool design.

“Stacked Wines was on board very quick with approvals, and those are the kinds of things that can bog a project down if approvals don’t happen fast enough,” Beason continues. “Email and phone calls were major communication tools. Even though they are on the west coast there was very little delay in communications. Since they were so very hands-on it just came down to building the tooling. Their original idea was well conceived so once we created the design with the requested finish and functions, the feedback/approval phase was on a fast track.”

“Each container was made in its own cavity with its own push up, according to Beason. “That means all of the cavities had to perform the same,” he says. “With each container being formed by a combination of several components, it is crucial that a bottle off any cavity would snap on containers formed by any other cavity.”

The unit tool was built in early June, with a final sample delivered three months later; and the production tool was shipped November 10th. “Thanks to the technical support of R&D/Leverage, we commercialized a breakthrough concept loaded with consumer and trade appeal,” Zimmer notes. “Regional sales volumes have validated our vision. As a result, we will continue to expand distribution and, in time, become a national brand.”

“I am still excited about this project,” Beason emphasizes. “What stood out for me was that this was a fresh idea from a small group of people that were so enthused about it, and to be able to work so closely with them and see their excitement and anticipation build as the project moved forward really set it apart from others for me. It felt very grassroots.”

Zimmer adds, “As a start-up, with limited capital and a new concept, we needed to get into production fast and have the design and tooling right—the first time. “R&D/Leverage proved to be a great partner to work with, and they delivered on all counts."

For More Information

R&D/Leverage, LLC / (816) 525-0353

Stacked Wines, LLC / (714) 870-1227

info@stackedwines.com / stackedwines.com

Related Content

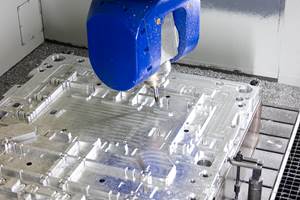

True Five-Axis Machine Yields More Throughput, Greater Productivity

CDM Tool & Mfg. Co. LLC increased shop capacity thanks to a versatile high-speed/high-accuracy five-axis Fooke mill capable of cutting very large workpieces quickly and accurately with fewer setups.

Read MoreLarge Hybrid Steel Insert Solves Deformation, Dimensionality, Cycle Time Problems

DMLS printers using metal additive powders selected by Linear AMS to produce high-quality, accurate, consistent 3D-printed mold components with certification and traceability.

Read MoreCAM Automation Increases Mold Production, Quality

Mold builder switches CAM software package after 20 years to take advantage of innovative programming strategies that reduce mold machining programming and processing times.

Read MoreOEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

Read MoreRead Next

Customized Software Speeds Design of Complicated Tool

When Woodland, WA-based injection mold manufacturing facility AIMMco needed a software program to create an extremely complicated tool, they looked no further than manufacturer Delcam (local Pasadena, CA office) to provide a CAD/CAM solution to best fit the company’s needs.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.jpg;maxWidth=300;quality=90)