Medical and Aerospace

Medical production is likely to see accelerating growth, while aerospace is already experiencing solid, consistent growth.

Medical Production Likely to See Accelerating Growth

Since the early 1970s, real medical care spending has increased virtually on a straight line. However, once the Affordable Care Act (ACA) was passed, the slope of that straight line increased, meaning the rate of growth in medical care spending increased. So much for the affordable part of the ACA.

The one-month rate of change (the current month compared with the same month one year earlier) shows that real medical care spending has increased by 5 percent or more each of the last five months. The last time that happened was June through October 2002. In fact, you have to go back to the fall of 1981 to find the next previous period with growth in medical care spending as fast as it is today. As a result of the extremely fast month-over-month growth, the annual rate of change in medical care spending has reached 4.1 percent, which is up from 2 percent in November 2013. This is the fastest annual rate of growth in medical care spending since May 2003.

Medical care spending is a good leading indicator of medical equipment production, which, generally, is on a two-year cycle. That is, from a peak or trough in the rate of change (see the chart) it takes about two years to hit the next peak or trough. But the amplitude of the peaks and troughs tend to rise and fall with the direction of medical care spending. In 2014, medical equipment production grew at an accelerating rate in response to the accelerating growth in medical care spending. Despite the rapid acceleration in medical care spending, however, medical equipment production has seen slower growth in 2015. Given the strength of the surge in medical care spending, it is quite possible that medical equipment production will hit a rate of growth between 7 and 9 percent around the end of 2016.

Aerospace Experiencing Solid, Consistent Growth

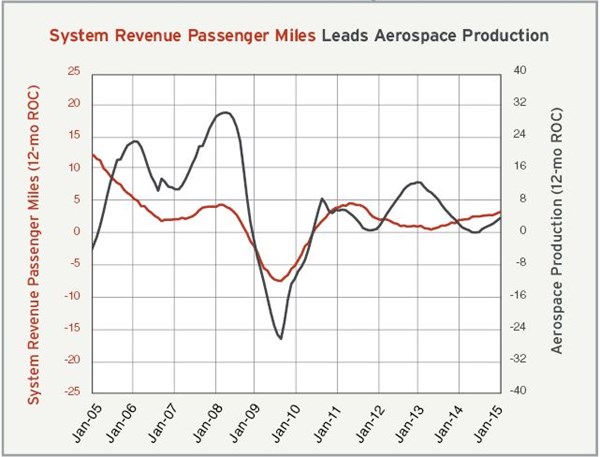

Generally, the leading indicators for the aerospace industry have seen solid and fairly consistent growth for a year or more. Real disposable income has been growing at an accelerating rate for more than a year, for example, indicating that both revenue passenger miles and consumer spending on air transportation services should grow at an accelerating rate. The growth rate in both has moderated, but that should change if the historic relationship between incomes and spending or air transportation holds. While aerospace production has been somewhat soft to start 2015, the leading indicators show that growth in production should improve in the second half of the year.

In addition to general economic indicators, our aerospace business index has been generally positive. The overall index had seen accelerating growth from the spring of 2014 to January 2015. Then the industry hit quite a soft spot, although growth resumed in the most recent month of data. New orders have been fairly positive, while production has been somewhat weak, just as the macroeconomic data indicates. Future business expectations remain strong, however, as the production needs for new engines remain quite robust.

Related Content

MMT Chats: Solving Schedule and Capacity Challenges With ERP

For this MMT Chat, my guests hail from Omega Tool of Menomonee Falls, Wisconsin, who share their journey with using enterprise resource planning (ERP)—and their people—to solve their schedule and capacity load monitoring challenges.

Read MoreThink Safety: Eliminate Hazards Throughout the Shop

The tooling community is taking advantage of new products for safer mold shops and molding facilities.

Read MoreDynamic Tool Corporation – Creating the Team to Move Moldmaking Into the Future

For 40+ years, Dynamic Tool Corp. has offered precision tooling, emphasizing education, mentoring and innovation. The company is committed to excellence, integrity, safety and customer service, as well as inspiring growth and quality in manufacturing.

Read MoreThe Trifecta of Competitive Toolmaking

Process, technology and people form the foundations of the business philosophy in place at Eifel Mold & Engineering.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.JPG;width=70;height=70;mode=crop)