Too busy during the holidays to keep track of MoldMaking Technology’s daily product posts? We’ve got you covered.

This is MMT’s second digital-only product/service roundup to keep you informed and your shop engaged in the latest and greatest products that are being offered in the moldmaking industry headed into the new year.

Representing a diverse range of categories and companies, this article represents only a small portion of the the new/proven products we’ve posted, so head on over to “New Tech” on the homepage, or check out the January print roundup for more.

Mitsui Seiki’s VGi20A ball screw nut grinding multitasking machine performs grinding and machining in one chucking, slashing nut processing time by two-thirds, says the company. The combination of grinding, multitask machining and automation strategies gives the machine its true advantage. With five axes of motion and storage for 40 tools, the machine can grind thread grooves and also machine the nut circumference, end surface, key grooves and return tube holes in a single setup.

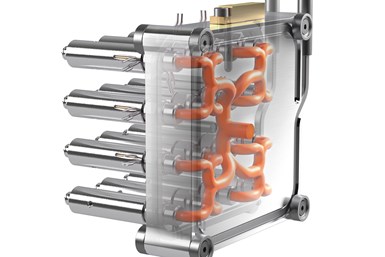

Hasco’s Steamrunner is the culmination of the company’s move into additive manufacturing for hot runner manifolds, which it first started back in 2016.

The company says that as an additively manufactured hot running manifold, the Steamrunner offers moldmakers and injection molders unprecedented freedom in design. Using this technology, manufacturers can configure flow channels with optimum rheological layouts, avoiding sharp edges and areas with poor flow.

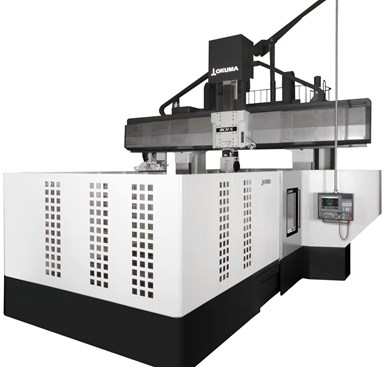

CNC machine tool manufacturer Okuma America Corp. debuts the MCR-S double column machining center (DCMC), which roughs and finishes press dies in one setup and is designed for heavy-duty machining of process-intensive press dies. It features full 5-face and 5-axis machining and is excellent for die repair work.

Okuma adds that its MCR-S won a “2019 Best 10 New Products” award by Nikkan Kogyo Shimbun (Business & Technology Daily News).

The L.S. Starrett Company a global manufacturer of precision hand tools and gages, metrology systems and more, introduces the AVX550 Multi-Sensor Vision System, a powerful, easy-to-use multi-sensor measurement system which streamlines and optimizes the QC process. Using a single system, production parts can be examined on the shop floor or in the QC lab on macro and micro levels as one comprehensive process.

The Starrett AVX550 Multi-Sensor System features dual optical systems that work in tandem to measure a broad range of features and a touch-probe capability to measure parts with a diverse range of feature sizes and geometries.

DMG MORI’s DMF 200|8 five-axis traveling column machine offers a larger work range than ever before, opening new possibilities for machining complex components. “With a rigid table measuring 2,300 x 850 mm and traverse paths of 2,000 x 800 x 850 mm, the DMF 200|8 offers users in die and mold and aerospace sufficient scope to flexibly machine even long structural components or mold inserts,” Markus Rehm, managing director of DECKEL MAHO Seeback, says.

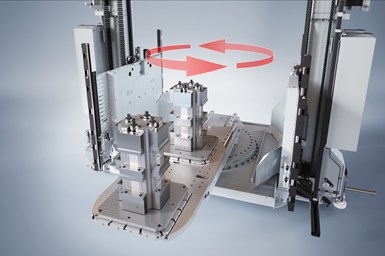

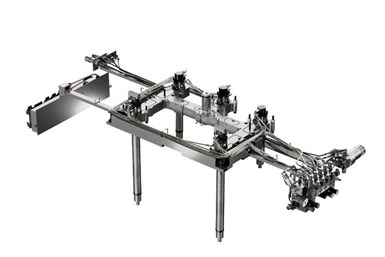

Fastems LLC’s new, multi-pallet load handler, the Double Mast Crane- Automatic Pallet Changer (DMC-APC) is a device that can be configured into an FMS (Flexible Manufacturing System) for machine tools that do not feature automatic pallet changers. Able to load machine tools directly and act as an automatic pallet changer, DMC-APC accommodates payloads up to 2,200 lbs (1,000 kgs). Further, says Fastems, manufacturers will no longer need to purchase and integrate costly APCs to machine tools in order to configure an FMS in their facilities.

The new Hasco cooling range offered in stainless steel ensures the reliable cooling of injection molds when using hot or cold water or heat-transfer oil. Manufactured entirely from high-quality 1.4305 material, the robust, safe and easily coupled Hasco system is said to guarantee reliable, absolutely leak-proof and durable temperature control applications, including in cleanroom environments.

According to Hasco, the standard temperature components in stainless steel are equipped with optimized FKM quality seals and can be used at temperatures of up to 150°C for water and 200°C for oil.

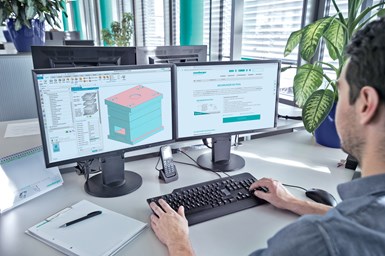

Together with its customer Schmidt WFT, Meusburger has developed a free CAD tool and library for the Siemens NX CAD system, enabling designers using the system to save time with the tool’s simple processes. Designers can selected configurations of components native to the system and automatically adjust all parameters. Installation spaces and the color table standards Meusburger developed together with the Association of German Tool and Mold Makers are also integrated in the tool.

BORIDE Engineered Abrasives has extended its Ceramic Super Stones line to include three new fine grits with ratings of 1,500, 2,000 and 3,000. The company advertises these new entires for semi-finishing, final finishing and mirror polishing on molds and dies, saying they result in a smooth polished surface and excellent polishing results.

HRSflow’s new hot runner systems feature technology designed to increase product quality in cascade injection molding.

HyFlow is HRSflow’s solution for applications with hydraulically actuated cylinders. HyFlow uses a controller with a user-friendly interface to set each individual pin’s lock position, and includes a manual adjustment mechanism to control each nozzle’s opening and closing speed.

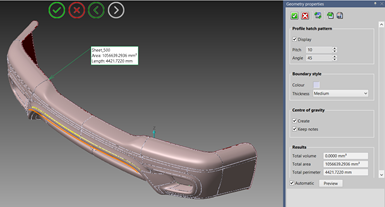

Hexagon unveils a range of new and enhanced functionality features— including CAD, Mold, Progress, CAM, Simulation and Wire Functions—in VISI 2021, the company’s specialist mold and die CAD/CAM software. Each feature is provided in more detail in the full product posting.

Desktop Metal is launching its Shop System metal binder jetting solution. The company says its binder jetting technology prints metal parts in volumes and at part costs unattainable with legacy additive manufacturing processes.

The Shop System is designed to bring metal additive manufacturing to machine and job shops with an affordable, turnkey solution that manufactures complex parts at speeds up to 10 times those of legacy powder bed fusion additive manufacturing (AM) technologies

The CUMSA sprue adjuster (SA) family is growing with two new 24-mm-diameter models, SA240022 and SA240822, both of which are suitable for larger molded parts with large runner gates. These units will allow the user to switch off and turn around the gate runner. CUMSA designed the two models to suit applications both where the ejector pin is required and where it is not.

GROB Systems has announced the availability of its new G150 horizontal five-axis machining center, part of the modular G-series system line the company says has continually set the bar for productivity and process safety.

GROB recommends the G150 for the precision engineering, medical technology, mold and die, mechanical engineering and aerospace industries.

.jpg;maxWidth=300;quality=90)