Machining Centers Offer High Quality, Programming Power

This moldmaker’s CNC machining centers don’t need separate software to write CAM programs—saving time and money without sacrificing quality

Sioux Chief Manufacturing, Inc. (Peculiar, MO)—an integrated, global supplier of PVC pipe, which is used in residential and commercial plumbing—has continually upgraded its ability over the past several years to produce all of its required plastic injection molds in its own toolroom. Vital to its capabilities has been the purchase of six CNC machining centers from Hurco Companies, Inc. (Indianapolis, IN)—a producer of interactive computer controls, software and computerized machine systems for the worldwide metal cutting and metal forming industries.

According to Sioux Chief Senior Tooling Manager Joe Stegmeier, as the company has grown, so have demands for larger multi-cavity molds. The shop needed to find ways to reduce programming and machining time while still maintaining quality. And, the machines Sioux City chose would have to be able to handle drilling, tapping and machining operations these larger molds require.

Control/Machining Power

After researching a number of machining center options, among the reasons Stegmeier chose Hurco was because the company’s control can generate all of the features and surfaces he needs for his molds. “By using Hurco’s optional 3-D software package, all of the curved surfaces in the pipe elbows and other sections can be generated for both core and cavities,” Stegmeier explains. “For the 3-D surfaces, we model the surfaces as revolutions or translations of simple 2-D cross-sections. With the print and the Hurco control, the machinist has all of the information he needs to create complex programs.”

In addition, Stegmeier doesn’t have to use any separate CAM software to write his programs. “All of the mold base and ejector plates are programmed right at the machine on the control as needed,” he states. “If a CAD drawing is available, it can be directly loaded into the control with a simple point-and-click that generates the required part features. Then, Hurco’s exceptional machine rigidity and advanced servo motion technology produces high quality machined surfaces.”

Less programming time is another feature of Hurco’s CNC machining centers. The machines’ loop and pattern sub routines minimize programming time—especially with larger multi-cavity molds. Sioux Chief’s latest Hurco addition—the VMX50, a 50" x 26" x 24" vertical machining center with a 10,000 rpm, 25-hp spindle—can handle mold bases up to 3,000 pounds and still reach 3-D contouring rates of 600 ipm. And, the control is equipped to automatically shut down the machine at program completion, so it is suitable for lights-out operation for long 3-D surface work. “The high torque available is ideal for large hole drilling and tapping in addition to heavy steel milling,” Stegmeier adds.

Two of the six Hurco machining centers in the Sioux Chief toolroom provide 30" X-travel and are arranged so that one man programs, sets up and runs both machines. “Hurco’s machines also have the unique ability to easily make copies of a base program and repeat them to build the final product, which slashes programming time dramatically,” Stegmeier points out. The VMX24—the smallest machining center at Sioux Chief—offers a 12-hp, 10,000-rpm spindle that is perfect for generating fine surface finishes on small parts, he adds.

Keeping Busy

Stegmeier emphasizes that his most important assets are his workers, and keeping things as simple as possible for them to get the job done right the first time is a priority. “Hurco’s powerful machines make programming and running parts simple for all of them,” he notes. “I can keep all six Hurco machines busy with my three-man staff. I could add two more Hurco machines before I would need to hire additional personnel to run the machines.”

Sioux City couldn’t be happier with its Hurco CNC machining centers. “They are indispensable for our operations,” Stegmeier emphasizes. “No other machine and control combination can give us the shop floor programming power and machining quality that is vital to our manufacturing operations.”

Related Content

CAD/CAM Software Reduces Delivery Times by 70% With a Six-Month ROI

Single integrated CAD/CAM package reduces translation errors, simplifies design process, improves shop efficiency and shortens tool lead times.

Read MorePrecision Welding Services Offer Rapid Turnaround Mold Repair and Reduced Molder Downtime

X-Cell Tool & Mold relies on outsourced, high-quality welding repairs from Lewis-Bawol Welding to ensure its customers' molds are back in production quickly and affordably.

Read MoreCT Scanning Helps Micro Molder Reduce Cost of First Article Inspections

CT scanning services performed by 3D ProScan, a division of NyproMold Inc. provides MTD Micro Molding with accurate, high-resolution internal and external measurements performed about seven times faster and at significant cost savings.

Read MoreIntegrated CAD/CAM Streamlines Electrode Manufacture, Improves Quality

A focus on electrode design and automation helps toolroom improve efficiency, reduce tooling costs and deliver higher quality products.

Read MoreRead Next

Consider The Control Before You Buy

Your machining center’s control could mean the difference between rapid productivity and costly downtime.

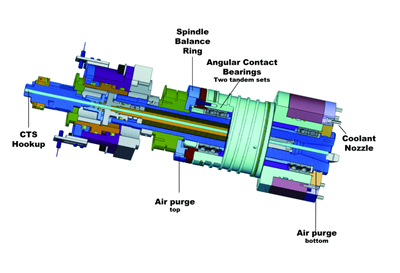

Read MoreMachining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreRediscovering CAM

Exploring underused CAM features that can improve moldmaking productivity and trim operating costs.

Read More

.jpg;maxWidth=300;quality=90)