Lowering Tooling Cost by Using Low-Friction Coatings

There are many components to the mold manufacturing process, but from a cost benefit approach to productivity, tooling technology is going to yield the biggest return, and coating technology is key.

As manufacturing becomes more global and more competitive, industries are forced to reevaluate how they look at cutting tools and machining processes. Logically, if a manufacturer invests in a high quality machine tool, but not the associated tooling, one may not be capitalizing on the true potential of their investment. Equivalently, if a manufacturer’s processes are not evolving with increases in tooling technology, one may not be reaching the potential of their prior investments. Either way, productivity yields profitably and the manufacturing mentality has changed from trying to be “The best in a field” to “The best in the world”.

There are many components in the manufacturing process, but from a cost benefit approach to productivity, tooling technology is going to yield the biggest return. In recent years, that productivity has come in the form of new grades of carbide, new grinding technology and new coating technology. Although all of the components of a cutting tool are important and associated, the element that is going to handle the heat of increased cutting speeds and performance is coating technology. The purpose of this article is to explain coating technology, describe recent coating advancements and illustrate differences with machining examples.

Coating Technology

Since the introduction of the first PVD (physical vapor deposition) coating (TiN) in the early 1980s, PVD coatings have become an industry standard. Over the past 30 years, PVD coatings have expanded to include: TiN, TiCN, TiAlN, AlTiN, CrN and countless others. For the majority of die/mold machining applications, the AlTiN PVD coating has been the most widely used for cutting tools.

Recently, PVD coatings have been expanded to include various multi-layered, hybrid coatings categorized as low-friction coatings. These coatings have provided an irreplaceable machining solution in materials that require a low cutting speed or are highly abrasive. Low-friction coatings are a crucial component of high-speed machining because as the cutting speeds increase, more heat (i.e. friction) is generated in the machining process.

Effectively managing this increase of heat will result in better surface finishes, more accurate part geometry, and most importantly an increase in productivity through an increase of tool life. This can be evaluated two ways:

1. An increase of tool life can result in a lower tooling cost per cavity or core, which will increase the profit per job.

2. An increase of tool life can be sacrificed for an increase in productivity. This would be keeping tooling cost the same, but increasing a shop’s throughput with increased cutting parameters

As a result of their extremely low-friction coefficient and wear rate, low-friction coatings offer a way to make any machining process more efficient. Correctly implementing and applying these new coatings into your manufacturing processes can reduce cost, increase productivity or both.

Applying Low-Friction Coatings

To illustrate how low-friction coatings can increase productivity and reduce tooling cost, a test was conducted using standard industry coatings as a benchmark. All components of the manufacturing process were kept constant except replacing the standard industry coating with a low-friction coating.

Example 1

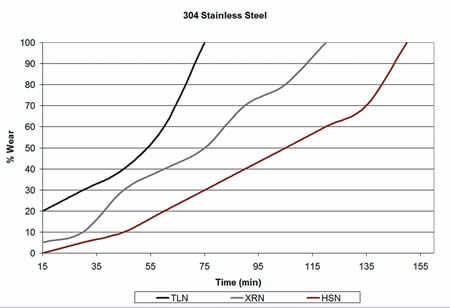

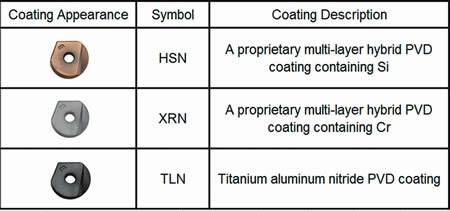

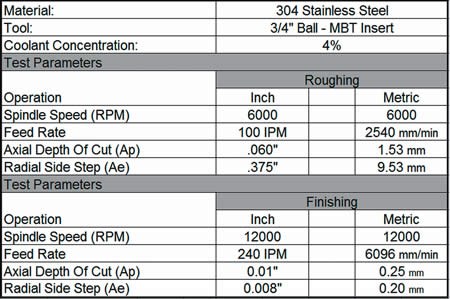

The objective of example 1 (see Charts 1ab) is to illustrate the benefit using a low-friction coating in materials that require low cutting speeds. For this example, a 304 stainless steel was chosen for the test material and an AlTiN-coated cutting tool was chosen for a benchmark of tool life. This benchmark will be compared to two low-friction coatings under the same testing conditions.

From Chart 2—keeping all machining variables constant—we can conclude by replacing the conventional AlTiN coating with a low-friction coating, tool life increased by approximately 30 percent using the XRN coating and approximately 50 percent when using the HSN coating. This can result in a 50 percent tool cost savings when using the HSN coating or can be sacrificed for an increase in productivity.

Example 2

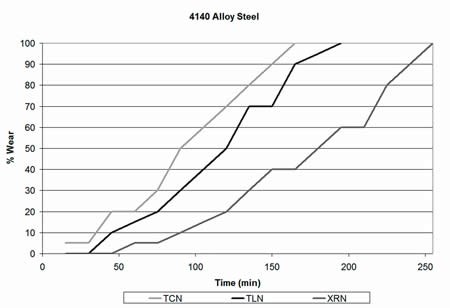

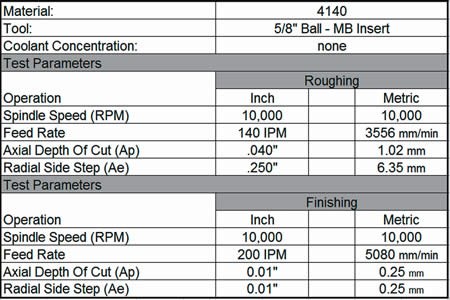

The objective of example 2 (Charts 3a,b) is to illustrate the benefits of low-friction coatings in general machining applications. For this example a general-purpose, high tensile alloy steel was chosen and for the test material and a TiCN-coated cutting tool was chosen for a benchmark of tool life. This benchmark will be compared to the industry standard AlTiN and to the low-friction coating XRN under the same testing conditions.

From Chart 4—keeping all machining variables constant—we can conclude by replacing the conventional TCN coating with the AlTiN coating, tool life only increased by approximately 15 percent. However, by using the low-friction XRN coating under the same cutting conditions, the tool life increase by approximately 35 percent.

Conclusion

When comparing results for both experiments it is easy to see the benefits and

consequences of coating technology. Leroy Tool and Die (Leroy, MI)—where this test was conducted—believes in low-friction coatings.

“Recently, we have put a lot of effort into testing to see what works best. The longer the tool life has increased our productivity,” says Mike Steinman, CNC supervisor. Low friction coatings are crucial components for the future of high-speed machining and manufacturing.

As a result of their extremely low-friction coefficient and wear rate, low-friction coatings offer a way to make any machining process more efficient. Cutting speeds will continue to increase and proportionally more heat is going to be generated. Effectively managing this increase of heat is critical to follow the future trends in manufacturing and increasing productivity.

Today’s manufactures are constantly seeking new ways to remain competitive in a highly competitive market and also increase profit. Oftentimes, manufactures are faced with large purchases of new equipment or hiring more employees to achieve that goal. However, by analyzing your machining process and applying some of the latest coating technology, shops may find a low-cost, easily-transitioned solution to increase productivity, increase profit or both.

Acknowledgment

Eric Wanstead: General Manager, Leroy Tool & Die; Mike Steinman: CNC Supervisor, Leroy Tool & Die.

Related Content

Fundamentals of Designing the Optimal Cooling System

The right mold components can help improve mold cooling and thereby produce higher-quality parts.

Read More6 Ways to Optimize High-Feed Milling

High-feed milling can significantly outweigh potential reliability challenges. Consider these six strategies in order to make high-feed milling successful for your business.

Read MoreLaser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreTreatment and Disposal of Used Metalworking Fluids

With greater emphasis on fluid longevity and fluid recycling, it is important to remember that water-based metalworking fluids are “consumable” and have a finite life.

Read MoreRead Next

Using High-Feed Machining Strategies to Get to Net Shape

High-feed tooling and high-feed machining could be the key factor in maximizing your shop’s roughing efficiency.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

.png;maxWidth=300;quality=90)