Interchangeable Plate System Saves Moldmaker Time and Money

It's not just a mold building "product", it's a "method" for better moldmaking.

Sit back, close your eyes for a moment and picture this - it is a scenario that every moldmaker has encountered at least once. You have been contracted for an important job where time is a critical factor. You get the design, build the mold base and are ready to go when the customer has a sudden design change. What do you do? Typically, this would mean going back to square one - costing both time and money to you and the customer.

However, there is an alternative ending to this scenario. Imagine that instead of starting over, you could order a new plate that would fit perfectly with your existing mold base. This would decrease not only the cost, but also the time lost in waiting for the new materials.

Scott Taylor, president of Peerless Injection Molding, Inc. (Torrance, CA), is one moldmaker who frequently feels the pressure of having to finish projects quickly. "We are both a custom injection molder as well as a toolmaker," says Taylor. "We sell our customers on a one-stop shop type of approach - we put all of the responsibility under one roof."

Taylor feels that there is a growing trend toward pulling moldmaking and molding into the same shop. "What is driving that is the time-to-market phenomenon," he says. "It's an order of magnitude change in the expectation of the customer in terms of delivery. Most of our deliveries occur in the three- to 12-week range."

For this reason, Peerless Injection Molding - which serves the dental and medical, electronics, computer peripheral, irrigation and cosmetic markets - has been working with a new interchangeable plate system for its moldmaking side of the business. "We use the interchangeable plates when a customer has more than one configuration that goes into the same mold base, or when a change is made late in the cycle or after the tool is done," says Taylor.

According to Taylor, the interchangeable plate system saves both time and money. "We had a prototype mold that was machined in solid into the plate itself - as opposed to having inserts," he says. "However, after the prototype was built, the customer changed the size of the main part and wanted a whole new prototype. We bought another plate and put it in the very same mold base. It only cost us $600 and four days of work. Without this system, we would have had to start from scratch or put in inserts. It was both a time and cost saver."

Peerless Injection Molding is able to do this because its supplier, PCS (Fraser, MI), carries an unusually large inventory in plate sizes and thickness - ranging from 7 7/8" x 7 7/8" through 19 1/2" x 23 3/4", which allows for shipping within 24 hours. In addition, PCS also carries mold bases and plates in the B series. "The accuracy of its machine tool technology has allowed PCS to come back after the fact and make plates to fit the mold bases," says Taylor.

In fact, the system allows mold bases to be assembled from individual plates with the assurance of a perfect fit on the exterior of the base - from the matching of pockets to exterior plate alignment. This allows for rapid mold base assembly and shipment, as well as the ability to order new plates from stock that can be inserted into an existing mold base.

However, in order to use this system effectively, the mold base must also be from PCS, and it has to be within a certain size series.

"The thing that I like most is that we can work on the tool here and order the plate from PCS," says Taylor. "They do the machining work parallel with us, and we meet in the end to finish the mold. It's a win-win situation."

Related Content

Maintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

Read MoreMoldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

Read MoreLaser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreThe Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.

Read MoreRead Next

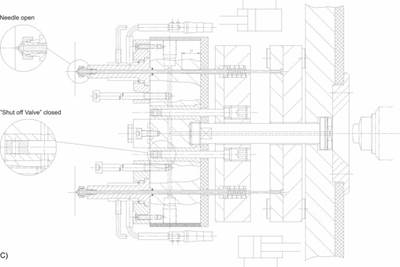

Designing 48 Individual Cavities in One Mold Plate

In the innovatively designed multi-cavity mold described here, every cavity has its own plunger injection system, ensuring that each cavity is filled completely and accurately with the desired amount of melt.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=970;quality=90)