How Design and Manufacturing Can Better Communicate

With the appropriate digital tools, product design teams can better align beautiful organic designs with manufacturing requirements early in the game.

Design for manufacturability is not a new concept, nor is the use of digital solutions for the many steps in mold design. Yet it remains a daunting task to rapidly produce cost-effective manufacturing molds for complex organically-shaped products.

There’s the classic yin and yang of designer and moldmaker: the designer creates a highly sculptural design with intricate details—a product that will attract and entice consumers as they are bombarded with choices on retail shelves. However when the designer hands off their approved design for manufacturing, the moldmaker typically says “The design is impossible within the timeframe and budget.” The dance of the compromise begins.

Add to that the typical outsourced production considerations, and product design teams quickly have the makings of costly delays and potential disaster. For example, Beme International, maker of highly stylized yet affordable hardware products sold at Bed Bath & Beyond, JCPenney and Lowe’s, reports that several years ago it would need to remake nearly 100 percent of its manufacturing molds in order to retain the highly organic, textured, architectural look of the original product design.

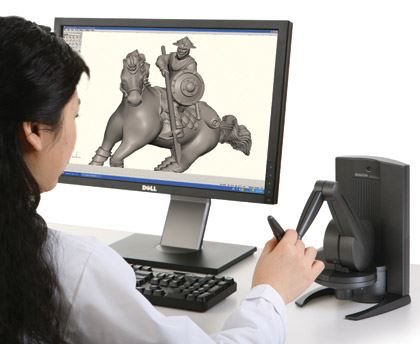

At Bastion Studios, makers of historical fantasy wargames and miniature game pieces, the exquisitely detailed nature of their tiny 32 millimeter-high miniatures—and a looming deadline for the company’s initial product launch—demanded that important mold design activities be completed with exceptional efficiency, without any overseas surprises.

With the right digital tools, product design teams can better align beautiful organic designs with manufacturing requirements, early in the game—when adjustments can be made faster and more cost-effectively, and before they become major, volume-run issues.

Sculptural CAD Saves Weeks, Improves Molds

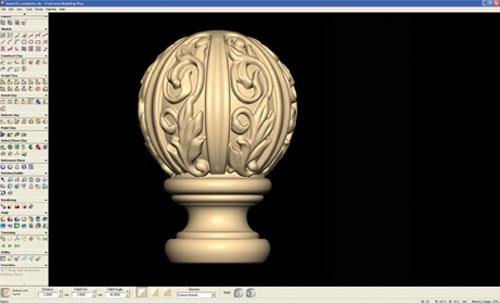

For Beme International, Bastion Studios, and thousands of product designers worldwide, the answer is sculptural CAD—a category of digital solutions that better accommodate the modeling and prep-for-manufacture of highly detailed, complex, organic designs. Some sculptural CAD solutions allow designers to work with digital clay and are based on voxels—think of voxels as 3-D pixels that can be easily repositioned, like a handful of shifting grains of sand.

Voxels allow extreme speed and design freedom and enable the natural “carve here, smooth there” actions typical of designers used to working with physical media such as clay, foam or wax moldmakers. They also provide the digital tool sets that designers need to analyze and adjust their models before sending them downstream for moldmaking and manufacturing—striking the perfect balance between aesthetics and manufacturability.

Sculptural CAD allows designers and moldmakers alike to optimize designs with an eye toward streamlined manufacturability, including:

Scan cleanup and refinement. Reclaiming lost features within scan data and sharpening detail is important in any mold, but challenging when the level of detail is high and parts are small. Sculptural CAD features help assure a quality mold by showing and allowing the removal of tiny artifacts and imperfections of mesh files in advance.

Analyzing moldability with draft analysis tools. The traditional process of establishing mold parting lines for a highly sculptural product. For example, a toy figurine where the parting line runs through the middle of the human figure, formerly could only be done by hand. For sizable product launches or products with a large number of parts, the task could be overwhelming. Sculptural CAD allows one-click design and analysis of parting lines for sizable time-savings—paving the way for clearer communication between product designer and moldmaker.

For example, Bastion Studios’ debut of its Ex illis™ medieval history fantasy wargame meant the company had to design molds for nearly 100 miniature game pieces in several months—each with highly detailed facial expressions, textures, clothing and weapons of medieval battlefields.

The company relied on sculptural CAD to streamline the initial design and then electronically delivered digital files to its partner Ghost Studio in China. There, a designer used the same sculptural CAD solution, relying on simple commands like Analyze draft and Pull Direction to color code front and back parts of the mold, clearly identifying undercuts and show potential details that might break when the mold was opened. As a result Bastion, was able to move from finished designs to final molds in just 2 weeks—instead of the typical 6- to 8-week process when using traditional sculpture, casting and pantographs.

Easy scalability to compensate for shrinkage. Making an allowance for shrinkage during the molding process can be very important for certain products that require fit and function—since thicker sections of plastic will shrink more than thinner sections. Within sculptural designs the section thickness can vary dramatically. Sculptural CAD features make it easy to analyze and upsize designs, so that finished molds will deliver perfectly detailed finished products.

For example, Beme International formerly hand built the grandfathers or oversized models of the final design that were used to make manufacturing molds. Working this way, the reject rate for finished production pieces were about 50 percent. By using a sculptural CAD solution to create a final design, Beme made a 3-D print that teams could view for accuracy and then used that as the grandfather, enabling them to cut remakes to less than 5 percent. This sped time-to-market—reducing time spent in manual mold design and allowing distinctive architectural detail that was important to its brand.

Support for sculpting shutoff surfaces with ease. Producing water-tight shutoff surfaces on organic models—with the types of complicated parting lines required to keep the designers original intent—is an especially arduous task. This is made even more complicated in family mold situations. By using sculptural CAD, mold designers are able to quickly model complicated shutoff surfaces, perform iterations to simplify machining and deliver final designs far faster than is possible with manual methods.

Creating family molds. Sculptural CAD allows swift layout of multiple parts united with sprues, such as game pieces. It gives the moldmaker the freedom to move parts rapidly, in a proxy mode, exploring all possible layouts to ensure well-balanced filling characteristics of a mold. Then automating alignment and replacing proxy models with the final detail models.

Putting Design and Manufacturing Teams on the Same Page

Sculptural CAD solutions are allowing organizations to better maintain the integrity of their designs, evaluate their designs for manufacturability more quickly, and deliver molds twice as fast. This level of design control and time saved represents a huge leap forward in prep-for-manufacturing efficiency and can lead to increased revenue opportunities.

Related Content

Making Mentoring Work | MMT Chat Part 2

Three of the TK Mold and Engineering team in Romeo, Michigan join me for Part 2 of this MMT Chat on mentorship by sharing how the AMBA’s Meet a Mentor Program works, lessons learned (and applied) and the way your shop can join this effort.

Read MoreThink Safety: Eliminate Hazards Throughout the Shop

The tooling community is taking advantage of new products for safer mold shops and molding facilities.

Read MorePredictive Manufacturing Moves Mold Builder into Advanced Medical Component Manufacturing

From a hot rod hobby, medical molds and shop performance to technology extremes, key relationships and a growth strategy, it’s obvious details matter at Eden Tool.

Read MoreTop 10 Topics to Cover During an ISO 9001 Manufacturing Audit

Take a look at this practical hands-on approach to conducting a quality audit.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.jpg;maxWidth=300;quality=90)