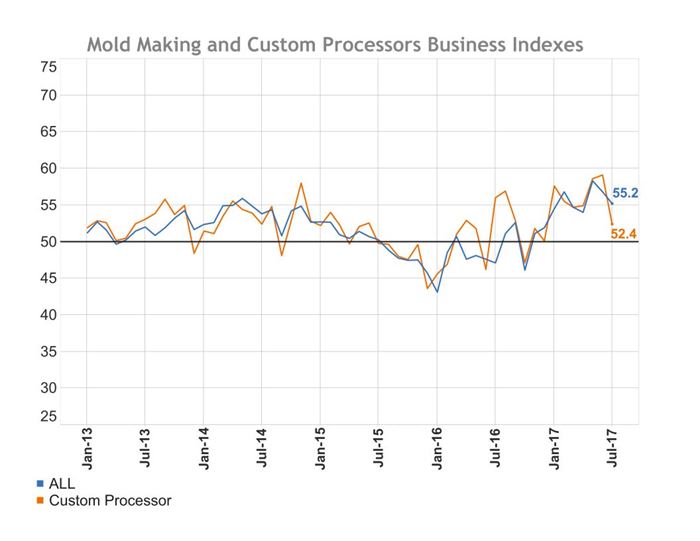

GBI: MoldMaking for July 2017—55.2

The Gardner Business Intelligence Moldmaking Index is up 16 percent from one year ago.

For July 2017, the Gardner Business Intelligence Moldmaking Index was 55.2. This reading shows that the Moldmaking Index has fallen slightly for a second month after it registered a new five-year high at 58.3 in May. Through the first seven months of 2017, the Moldmaking Index averaged 55.8, which is a 16-percent increase from the same period one year ago.

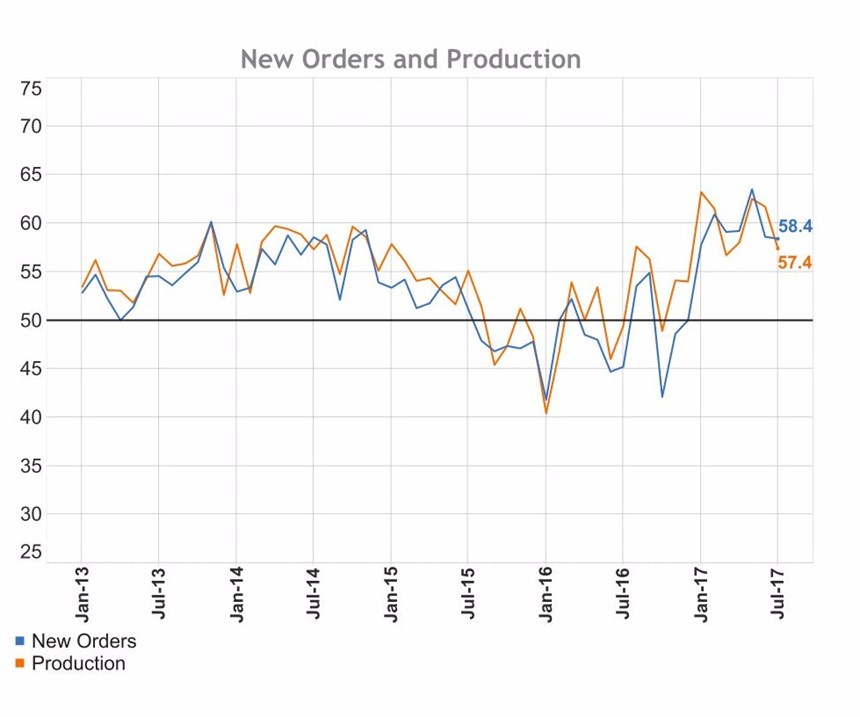

The new orders, production, supplier deliveries and employment components increased this month’s Moldmaking Index while backlog and exports decreased it. Examining custom processor responses only, the result for July was 52.4, which is down sharply from June’s five-year high reading of 59.1.

Both production and new order components have fallen since June, but in the year-to-date period they have increased nearly 6 percent and 16 percent, respectively. The turnaround in new orders, after a deep fall into contractionary territory in 2016, may explain partially the recent spikes in backlog readings. The GBI team closely monitors backlog, as backlog is often thought to be a bellwether of capacity utilization and machine tool sales.

During the past 12 months, the exports component has averaged 49.0 and has trended flatly. Fluctuations in currency markets can impact the relative pricing between foreign and domestically produced goods, so GBI closely monitors foreign exchange rates.

The spread between material prices components, at 65.4, and prices received components, at 51.2, increased in July. Material prices in the year-to-date period averaged 67.8, which was due in part to material prices reaching a new multi-year high in February. In contrast, prices received has stayed roughly within a five-point range between 55 and 50. While these two measures are not used to calculate the Moldmaking Index, they demonstrate how inflationary forces impact business profitability.

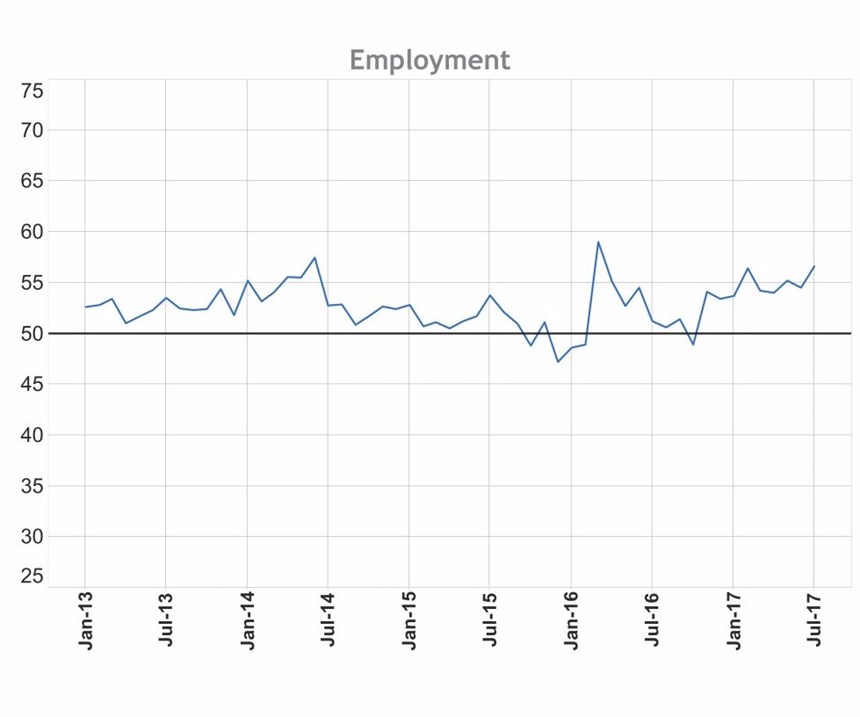

A greater number of moldmakers and custom processors report an increase in hiring. This has increased the employment readings 10 percent since July 2016.

Related Content

-

How to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

-

Mold Builder Uses Counter-Intuitive Approach for Mold Challenges

Matrix Tool Inc. answers customers’ hard questions with creative solutions for cavity spacing, tool sizing, runner layout and melt delivery that reveal the benefits of running in a smaller press size at lower cavitation but higher yield.

-

OEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

.jpg;width=70;height=70;mode=crop)