Commercial Tool & Die (CTD) deemed a recently acquired portal milling machine an ideal solution for the large-section automotive and truck molds this injection and compression mold builder produces, but this was not a purchase-and-place investment scenario.

As CTD Plant Manager Darin Hall explains, “We saw great potential in the FZ40 Compact portal milling machine from Zimmermann after encountering it at an IMTS event in Chicago, but there were certain modifications that we required on the machine.”

CTD is one of three business units operated by Commercial Tool Group (CTG) in Grand Rapids, Michigan. The other two units are CG Plastics and CG Automation & Fixture. Founded in 1953, CTG has grown from a small mold shop into a major supplier of injection and compression molds, fixtures, automated equipment and robotic handling devices to the automotive, appliance, heavy truck, RV and appliance industries, providing turnkey solutions to manufacturers of various plastic and composite parts.

CTG views technology as the foundation of its continued growth, so maintaining an aggressive technology investment strategy across all three business units is vital, especially at CTD, where they are “building the future of tooling,” according to the company. This strategy is why selecting a machine tool supplier committed to working with CTD to design and build a machine exactly to its specifications was key.

Seeing Potential

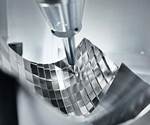

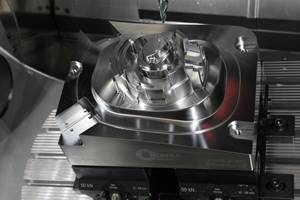

The CTD team was immediately impressed with the FZ40’s open design, overhead gantry, extremely solid base and rigidity. Its overall weight of 136,687 lbs and over 17-ton table weight capacity was twice that of the competing machines that Hall and his team considered. Plus, the powerful milling head features 137 horsepower and 424 ft-lb torque max, which allows steel and titanium machining. Also, the FZ40’s accuracy, with its rotary axis accuracy to 0.0001 degree, matched the demands of CTG’s optics and lens injection molds. And, the A- and C-axis clamping forces up to 4425 ft-lb of the VH60 milling head would allow the team to take full advantage of HSK100 tool torque and horsepower ranges.

Hall further notes that the rigidity provided by eight mounting elements on the machine was a real bonus for CTG, especially over long runs that produce the optimum surface quality required for automotive Class-A parts. On top of all that, CTD employs monitored, unattended machining operation, so the reliability and repeatability of the Zimmermann machine had high appeal.

Exceeding Potential

However, as Hall points out, there were certain machine enhancements CTD required. “We usually get pushback from machine builders when we request design changes, but the Zimmermann team was very responsive and flexible.”

Zimmermann has substantial experience in Germany with moldmakers using the FZ40 Compact, a machine designed specifically for the moldmaking market due to its open table design and gantry style multi-axis forked head configuration, but the company knew the machine’s capabilities could be expanded to meet the needs at CTD.

For example, mechanical and electrical changes in the machine’s design, as well as changes to the software on the Heidenhain CNC, which involved complex algorithms for detection and data calculation in the motion control scheme of the machine, were required to suit CTD’s applications.

Zimmermann also offered CTD a lease-to-buy agreement that allowed the shop to use the machine during the runout on the modifications. CTD documented and reported the results back to the builder, further improving the technology.

More specifically, CTD requested modified probes with extended lengths, extended Z-axis by 6 inches to accommodate longer tools, increased tool change capability from 12 inches to 16 inches to change longer tools and increased C-axis rotation to accommodate the larger, longer tools for five-axis programs.

Also, fine-tuning of gear boxes and motors to a 10% or more higher-load capacity in cooperation with Heidenhain engineering. Lastly, a new tool changer design for the extended lengths within the machine’s work envelope that are required by the extended Z-axis dimensions. “This was a unique challenge, as we were working hard to maintain the overall footprint and work envelope of the machine,” Zimmermann President Cornelius Keisel says.

All the modifications CTD required were thoroughly discussed, analyzed for feasibility and implemented in the final design of the machine. The process included fine-tuning the Z- and C-axis individual movements to achieve maximum surface finish quality, which the Zimmermann process engineering team simulated and validated onsite by the CTD inspection team.

“This allows us to eliminate most hand polishing operations, a substantial cost saver for us,” Hall says, “Secondary hand polishing requirements had been the norm here but are now radically reduced or even eliminated by the precision of the machining on the FZ40 Compact.”

As a result of the expanded capabilities, CTD was also able to take advantage of the high horsepower (137 horsepower) and torque (424 ft-lb) on the machine to improve cutting speeds up to 10% or more during mold machining. The CTD team used very aggressive machining strategies, running the spindles at speeds to 8,000 RPMs with HSK100 spindle technology that did not sacrifice RMS surface quality, as evidenced by the coordinate measuring machine (CMM) and laser checks performed onsite.

CTD also uses Zeiss CMM and Creaform laser 3D inspection technology to facilitate its quality control on the machine. CTD customers, especially in the automotive sector, demand such accuracy and process/workpiece validation. In production, the FZ40 Compact data are transmitted by the CNC to the CTD Epicor system, an ERP protocol that tracks all performance to plan, work schedules, comparative shift analysis and overall equipment effectiveness.

CTD also uses Powermill CAM software with CAM-to-machine tool integration, so they can perform part inspection before removing the workpieces from the machine. With the large mold sections typically produced at CTD, this feature is a significant advantage, as it yields a substantial reduction in logistics and material handling time in the shop.

The more flexible and powerful machining capability on this modified Zimmermann milling machine helps CTD machine parts more efficiently, which allows them to quote shorter lead times to customers and prospects to win more jobs

Making an Impact

Zimmermann also offered CTD a lease-to-buy agreement that allowed the shop to use the machine during the runout on the modifications. CTD documented and reported the results back to the builder, further improving the technology.

The more flexible and powerful machining capability on this modified Zimmermann milling machine helps CTD machine parts more efficiently, which allows them to quote shorter lead times to customers and prospects to win more jobs. “Zimmermann machine technology has improved our process with at least a 10 percent reduction in cycle times and no compromise in surface quality,” Hall says.

These results and Zimmerman's service made the teams’ decision to purchase additional machines easy. Not only were CTD’s requirements met on the new machines ordered, but they are highlighting the traditional green color scheme of Zimmermann with the Commercial gold coloring.

When the impact of all the machine modifications for CTD was realized, Zimmerman decided that it made sense to make these options available to others in the industry. Many of the changes will now become standard options on the machine in the future.

Video: Zimmermann Milling Machine Making Molds at Commercial Tool Group

Zimmermann FZ40 Compact milling machine in action, cutting mold sections.

The Zimmermann FZ40 Compact, a five-axis milling machine with a unique head and extended spindle design, is shown producing large injection molds at Commercial Tool & Die in Grand Rapids, MI, a leading moldmaker for the automotive industry.

About the Contributor

Keith Foster is vice president of sales and marketing for Commercial Tool Group.

Commercial Tool Group

616-785-8100

Zimmermann Inc.

248-305-9707

Related Content

Speed, Productivity Gains and High Uptime Ease Decision for Second Five-Axis Machine

Byrne Tool + Design reduced setups and gained speed and productivity thanks to fast, accurate and compact five-axis CNC machining centers.

Read MoreThe In's and Out's of Ballbar Calibration

This machine tool diagnostic device allows the detection of errors noticeable only while machine tools are in motion.

Read MoreTen Things You Need to Know about Circle Segment Milling

Considerations for evaluating if circle segment end mills or conical barrel cutters are right for your mold machining applications.

Read MoreFive-Axis Graphite Mill With Automation Debottlenecks Electrode Machining

Five-axis electrode cutting enabled Preferred Tool to EDM complex internal screw geometry on an insert that otherwise would have had to be outsourced.

Read MoreRead Next

Real-Time Mold Production

An automated five-axis machining/EDM cell offers a cost-effective alternative to series and batch mold manufacturing.

Read MoreFeatures and Functions of Five-Axis

Capitalizing on its unique characteristics can help you fully realize the potential of five-axis machining.

Read MoreGaining Control of Five-Axis Mold Machining

The CNC motion system is key to tackling the tight tolerances and superior finishes of modern mold manufacturing.

Read More