Vista Technologies LLC of Vadnais Heights, Minnesota, has discovered many avenues for using additive manufacturing to complement its mold building and injection molding divisions.

The company specializes in rapid prototyping, rapid tooling and injection molding, employing additive manufacturing technologies such as Objet’s Polyjet 3D printing technology and fused deposition modeling (FDM). Its in-house rapid tooling and plastic injection molding capabilities enable spec material parts to be produced fast—usually within one to three weeks. Utilizing high-speed machining, EDM and injection mold presses, VistaTek manufactures complex rapid tools and injection-molded plastic parts used for prototypes and short-run production (100,000+).

According to Dan Mishek, managing director and owner of VistaTek, “The benefit of having rapid prototyping, rapid tooling and injection molding all in-house gives customers the advantage of getting quality products to market fast, efficiently and inexpensively.”

Mishek explains that, traditionally, when it came to advancing manufacturing processes, people would pick a team on which to play: the additive manufacturing team or the subtractive manufacturing team. This meant that people used technologies such as FDM, Polyjet or stereolithography (SLA) for additive manufacturing, or CNC machining for subtractive manufacturing. As a result, he saw a divide created, which he believes left both sides feeling threatened and intimidated by the other.

However, times have changed. More successes are being documented, and people are beginning to use the technologies appropriately and have begun to rely on their own experiences to form opinions about the technologies’ roles.

The Disconnect

Additive manufacturing appeared quickly on the scene in the 1990s with claims that it was going to take over for machining and injection molding. “This immediately put traditional manufacturers on their heels,” Mishek says. When these traditional manufacturers evaluated the technologies regarding materials, tolerances and speeds, they were unimpressed and disregarded any potential. Materials were brittle, options limited, tolerances poor and costs high.

“Traditional manufacturers were offended that a technology—not requiring a trade school background, an apprenticeship or years of experience in the industry—could replace their skill set. On the flip side, additive manufacturers were unimpressed by traditional manufacturers refusing to advance product development with speed or diversity. Once the lines were drawn, both sides dug in their heels and refused to accept the other technology.”

The Change

But successful applications, and applications complementary to subtractive methods, are changing the minds of users, Mishek says.

He has seen the technology behind additive manufacturing become more affordable and the materials and tolerances greatly improve. “Parts can now be built in layers from 0.0006 to 0.006 of an inch, and materials used do not just mimic spec materials, they are true engineering-grade materials, such as ABS, polycarbonate, Ultem and PPSF,” Mishek says. With these advancements, the tides are turning and people are viewing additive and subtractive manufacturing not as competing technologies but as a complementary team.

The Applications

VistaTek uses additive manufacturing to complement its mold building and injection molding divisions. Polyjet parts and FDM parts are being used as go/no-go gauges, as well as jigs and fixtures for heat staking, pad printing, trimming fixtures, assembly and so on. These materials even allow parts to be used as inserts for injection molding.

“With faster speeds, better accuracy and more durability in the technologies and the materials, blending additive manufacturing with subtractive manufacturing has been at an all-time high,” Mishek says. “Great successes are being documented in every program using additive manufacturing.”

Jigs and Fixtures

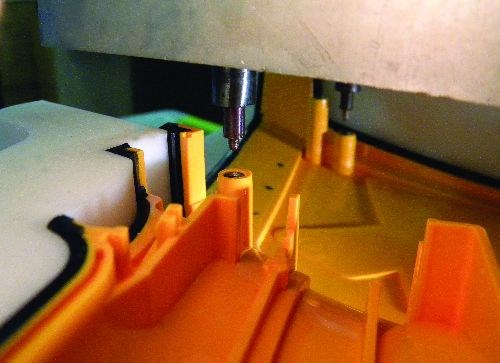

Every day at VistaTek, a jig or fixture is used to locate, insert or support something. Traditionally, these items have been machined, but this has involved expense and time to program the work, buy the material and machine the parts. Today, Mishek explains, FDM and Objet jigs and fixturing tooling are built overnight for next-day uses and successes.

According to Mishek, with commonly used FDM materials such as acrylonitrile butadiene styrene (ABS) and polycarbonate, the fixtures are strong and durable. Using Objet fixtures has made heat staking on cosmetic surfaces easy. A rigid material is used as the substrate, then a soft durometer is used as the overmold to be sure that it does not scratch the cosmetic surface.

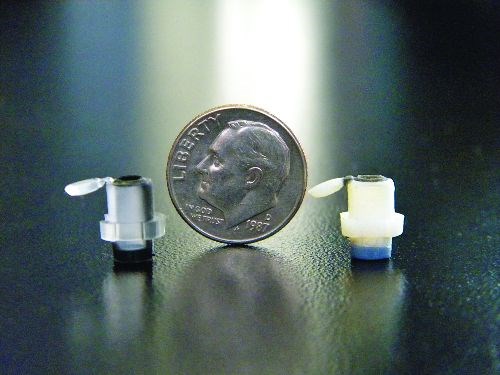

Mold Inserts

For hand pick-out or inserts, using additive manufacturing has been successful for VistaTek. “The durability of the materials is holding up to injection molding applications, working well for 25 to 50 parts,” Mishek says. Some applications yield 200 or more parts. “The cycles are slower per part, but the speed to market is a plus,” he says.

One of the biggest changes Mishek has seen is getting the mold designer and the tool shop manager on board and educated about making the use of additive manufacturing a standard practice in the toolroom. VistaTek’s mold designers are now trained to design fixtures, jigs and inserts early and upfront in the design stages. This enables these manufacturing processes to run in parallel through the shop.

Another great advantage of additive manufacturing for the designers is the chance to build an actual part and send it out to get sonic welding fixtures and horns built. “Typically, an injection molded part is shot, then the horns are built,” Mishek says. “This could add weeks or months of delays.”

The True Value

Mishek emphasizes that if you are not educated about additive manufacturing, you will likely use the wrong technology for the application. “The true value of this technology is found when you take the time to learn where each of these complementing technologies and materials make sense,” he says.

VistaTek has quietly embraced additive manufacturing where it believes it has value. For example, the company takes pride in assisting customers with their technology choice and material options. By suggesting a material that best mimics or emulates the production material, VistaTek can contribute to the customer’s product development success.

“Our company does not push an agenda with 3D printing or additive-manufactured molds,” Mishek says. “Although they do work, and there are avenues and design techniques for it, at the end of the day our customers want more than 50 to 100 parts. They also want to make design changes, and they want to shoot exotic materials.” Most of VistaTek’s quick-turnaround mold tooling is machined in aluminum rather than produced additively.

Still, on the additive side, VistaTek ships out 500 to 700 parts per week. That is a lot of parts off of six different platforms: five Objet 3D printers and one large-platform Stratasys 3D printer. Mishek notes that, in the end, this work is both production and not for production use. Because of the volumes, VistaTek is making prototypes in a production manner.

In fact, with the quantities of all the work moving through its shop, the company has had to find efficient ways to program, build, finish and ship products, and provide rigorous documentation and quality. The company’s other divisions are making a couple hundred molds each quarter and shipping thousands of parts each day.

“Being a true custom injection molder, we see many parts from different regions, industries, sizes and materials,” Mishek explains. “We have customers who need parts made and thrown into a box and other customers who need parts handled with white gloves, hair nets and double-bagged.” Embracing a diversity of processes has gone hand-in-hand with embracing a diversity of customers.

Summary

At the end of the day, a traditional mold manufacturer or injection molder can and should embrace additive manufacturing, because it is truly complementary to its existing processes and adds value.

“When customers see these technologies in-house, they feel more comfortable that they are working with a progressive manufacturer,” Mishek says. “This technology is no longer considered science fiction. It is here, and it is staying. Rest assured, once additive manufacturing is in-house, more applications and cost saving will be discovered.”

.jpg;maxWidth=300;quality=90)