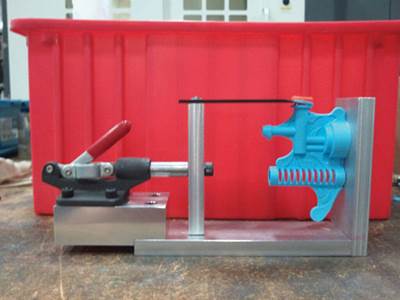

A complex, one-cavity injection mold was a game-changer for the Kid Caddie's design and functionality. Photo Credit, all images: Kid Caddie

Ben Fairbanks, an American innovator with roots in Brookings, South Dakota, is on a mission to change the way families experience golf. As a passionate software engineer based in Minnesota, he embarked on a journey that involved turning his dream into reality with the creation of the Kid Caddie, an ingenious golf accessory designed to promote diversity and inclusion in the sport.

Golf historically has an exclusive reputation, but the Kid Caddie encourages kids and families to engage in the sport. This accessory enables golfers to carry 18 clubs while also acting as a stroller — ideal for a primary golfer and a spouse so that they can both to enjoy the game. The Kid Caddie not only lowers the entry barrier to the sport, but also brings families together on the picturesque golf course.

Getting Injection Mold-Ready

The Kid Caddie (patent pending) is a sophisticated piece of engineering designed to be lightweight and perfect for families looking to enjoy a round of golf. The inspiration for this product came from the birth of Fairbanks’ daughter four years ago. From the outset, he aimed to create an injection mold to streamline the production process, but his challenge was finding the right balance between volume and cost-effectiveness.

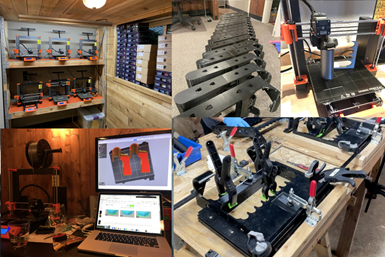

Ben Fairbanks built a 3D printing studio and hired several people to work out the Kid Caddie design before advancing to tooling.

For three years, he combined testing the Kid Caddie during Minnesota summers with refining his business plan during the winter months. Fairbanks was determined to get the design right, with version 6 preceding the use of 3D printing and version 20 representing the culmination of a lot of testing and iteration.

In the summer of 2022, with the product design ready, Fairbanks turned to social media to gauge interest from families and golf courses. His passion led him to create a 3D printing studio equipped with seven printers and a dedicated team. Initially, he aimed to print the Kid Caddie in one piece but encountered high waste due to scaffolding material and the risk of losing the entire print if one part failed. The solution was a four-part design joined with four connectors. He hired a local team with expertise in e-commerce and additive manufacturing to refine the design for an injection mold.

However, Fairbanks soon discovered that molders were hesitant to work with inventors who hadn’t fully developed their products. To reach the volume required for injection molding, he diligently built an email list of more than 7,000 interested parties across 31 countries, including individuals, distribution partners and retail representatives. The focus was firmly on the business-to-consumer model, aiming to scale and grow by implementing automated processes.

In the end, the Kid Caddie is a versatile piece of engineering that enhances the golfing experience.

Success on social media, including a viral video, brought the Kid Caddie to the attention of 5 million people, some of whom were key figures in the golf industry. This led to the Kid Caddie’s debut at the PGA Show in Florida, where it impressed and secured a fourth-place ranking among 110 companies.

After much searching, Fairbanks found local partners in Premier Plastics and Prairie Tool in Aberdeen, South Dakota, known for their quality work and management. The decision to invest $100,000 in the mold was a significant one, entirely self-funded and rooted in a passion project that he and his wife had been planning for four years.

Designing and Building the Mold

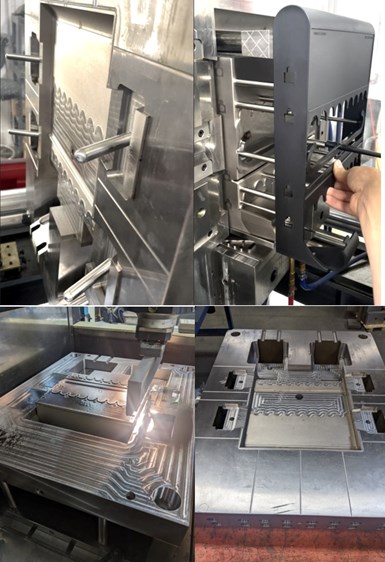

Premier Plastics and Prairie Tool of Aberdeen, South Dakota, took on the complex plastic injection mold and molding for the Kid Caddie.

A complex, one-cavity injection mold was a game-changer for the Kid Caddie’s design and functionality. From the first time, Premier Plastics’ Brandon Sigaty saw the prototype, he was excited by the concept. “As a father of a young child, the ability to enjoy a hobby while simultaneously enjoying time with your little one resonated with me,” he notes.

Sigaty chose to work with Prairie Tool because they have been his primary moldmaker for a long time. Premier Plastics has built a strong relationship with their entire team and they’realso located only a few miles away, which simplified working out the details and necessary troubleshooting.

As soon as the Prairie Tool team got their hands on the 3D prototype, they began to imagine how to make the part moldable. There were several virtual meetings early on to work through the mold design with Fairbanks, as well as continual updates on the process. “Often, customers with no injection molding experience have a hard time understanding why you can’t just manufacture a part as it was 3D printed, but Ben was quick to understand the limitations,” Sigaty says. “3D-printed parts are great for visualizing the final goal and helping work out the mold layout. As we made necessary changes, we shared STEP files with Ben so he could also print 3D parts and make sure everything still met his expectations.”

One of the most challenging aspects of the mold design was size. The mold accommodates various actions to create additional accessories, such as cup holders and ball and tee holders. The space required for the part and the required cam movements made the mold quite large.

The mold was originally cut to the minimum wall thicknesses that Sigaty expected would meet the strength and durability requirements while remaining “steel safe” to allow for future revisions. After a small run of parts, the teams made some immediate revisions to thicken specific areas of the mold and add reinforcements to other areas to increase rigidity and durability.

They also made a material change to an engineered acrylonitrile styrene acrylate/polycarbonate (ASA/PC) blend to add just a little more strength to the part. The use of ASA, a weather-resistant resin commonly used for outdoor applications, and a PC blend to increase strength, enabled additional ribs and enhanced strength, which wasn’t possible with 3D printing due to the scaffolding limitations.

“At one point, we suggested to notch the ends of the ball holder tray to utilize the natural shrink of the material,” Sigaty says. “Now, as the part cools, the plastic naturally pulls in and the golf balls snap into place. You can hold the part upside down and shake it without the golf balls coming loose.”

In the end, the Kid Caddie is a versatile piece of engineering that enhances the golfing experience.

As of June 2023, the Kid Caddie has completed its first production run, with more than 2,000 orders to fulfill. While the journey has been extraordinary, the challenges of building a team to help scale the business and meet both U.S. and international demand remain.

Ben Fairbanks and family not only helped bring the Kid Caddie to life, they use it out on the course together.

Looking Ahead

The Kid Caddie represents a unique opportunity in the world of sports. Golf creates lifelong customers, and the Kid Caddie enables families to bond over the sport, potentially ensuring customer loyalty for the next 75 years. Fairbanks’ vision for the Kid Caddie has not only brought a family’s dream to life but also has the potential to revolutionize the golfing experience for countless families and children, proving that innovation and passion can drive change in even the most established industries.

Read Next

When Is 3D Printing Cost Effective?

Hype continues to surround additive manufacturing. These three factors can help determine whether a part is worth 3D printing.

Read MoreThe Evolution of an Invention

The next generation of the Tie-Not balloon tying device—developed, designed, prototyped and molded by a mold base shop owner and his wife—posed many challenges due to the complexity of the mold design.

Read MoreInvent a Product—Not Just Its Mold

When Wayne Sikorcin, owner of Craftsman Tool & Mold Co. (Aurora, IL)—a moldmaker turned mold base builder—got frustrated tying water balloons at a family picnic several years ago, he decided to turn that frustration into innovation by using his moldmaking background, experience and connections to develop, design, prototype and mold a device that would tie a knot on a water balloon.

Read More

.jpg;maxWidth=300;quality=90)