Boots on the Ground at Mega Moldmaker Rexam

Last month I paid a visit to Rexam Mold Manufacturing to see firsthand how the company is incorporating automation into its operations with the Mega-Cell—an automation station that involves a number of leading manufacturers and suppliers.

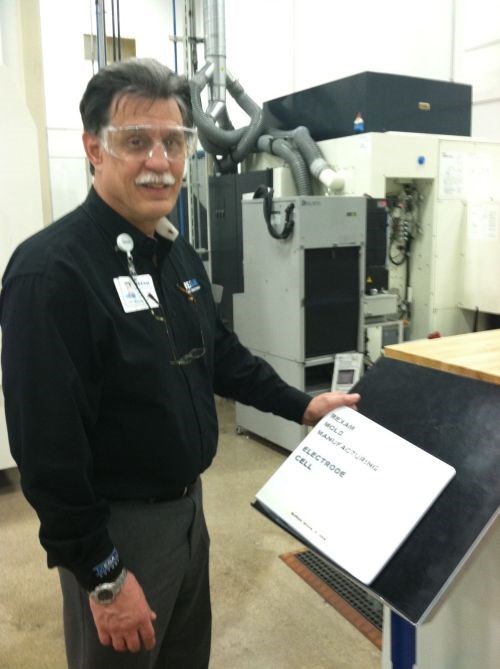

My tour guide, Rexam’s Business Unit Leader Len Graham.

Last month I paid a visit to Rexam Mold Manufacturing to see firsthand how the company is incorporating automation into its operations with the Mega-Cell—an automation station that involves a number of leading manufacturers and suppliers, which Len says will take the company to a whole new level of lights-out automation. “We will see automated mold building from start to finish!” he says. I was able to see robotic rail number one of five rails for mold insert manufacturing in place—with five machines in operation. After five additional rails are complete, a rail system to machine mold plates in an automated fashion will follow. It is a six- to seven-year, multi-million dollar plan, according to Len. This Mega-Cell is destined to be a game-changer for the company. Stay tuned to a future issue of MMT to learn all of the details about how industry suppliers like System 3R, Makino, Mitsubishi EDM, Delcam, SolidWorks, GF AgieCharmilles and Zeiss collaborated on rail number one of this project—and the competitive advantage it will undoubtedly bring Rexam.

Related Content

-

Revisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

-

How to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

-

The Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.

.jpg;maxWidth=300;quality=90)