Atlanta-based SISE Plastics Control Systems Inc. presents its generation of multizone controller technology (MV3), which will soon be able to control up to 336 zones. Available in five sizes (XS, S, M, L and XL) with three available power cards (2.5A, 15A and 30A), it adapts to various key markets, namely packaging, automotive, cosmetics, medical and technical parts. The company uses a 10- or 15-inch touchscreen display, running on Linux-based SISE software. With accessible power and thermocouple cards on removable pivoting shelves, this generation will have useful, advanced functions like four soft starts, zone grouping, PTI function for thermocouple anomalies, Moldscan for real-time hot runner diagnostics and material leak detection. The system is multilingual (up to 11 languages available) and offers unlimited mold file memory. Lastly, the MV3 communicates with IMM’s and can save and monitor production temperatures, perfect for Industry 4.0 installations.

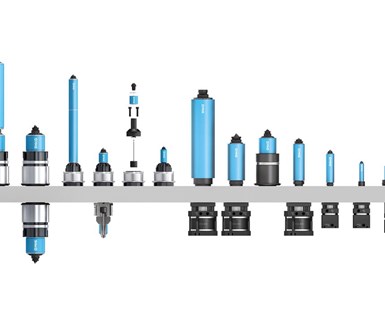

Mold Hotrunner Solutions Inc. (MHS) expanded its line of cooling-free valve gate actuators to cover a full range of injection molding applications. MHS has expanded both product lines for the new internally actuated Rheo-Pro iVG nozzles and the manifold mounted black box cylinders. MHS says that both product lines for the new internally actuated Rheo-Pro iVG nozzles and the manifold mounted Black Box cylinders have been expanded to bring their performance to plastic part applications of every size and for every industry. The products are built without o-rings entirely so that the products can withstand being worn out by force or heat, even at temperatures of 850°F. MHS says that because the pistons have no soft seals or lubrication, they require virtually no maintenance over the life of a mold.

Hasco’s Hot Half H4400/… system comes fully equipped with all the hot runner components and nozzles, as well as the clamping, bolster and nozzle retainer plates, plus the standard components and connectors, and is ready for immediate use.

In addition to checking the mold-specific dimensions, all the drive and connection components are tested to ensure proper functioning. All the test results, documented in corresponding test reports, are included in the delivery. The Hot Halves are equipped with a USB 2.0 data storage device which contains all the available information, such as drawings, parts lists and measurement protocols. Regardless of where the mold is used, the data can be called up directly from the system. As an information storage device to accompany the mold, the screw memory A5805 can be used to archive all the mold and/or article-specific data directly in the mold. It can then be read out at any time without any need for a data cable.

Labels for connector assignment are permanently affixed with slotted pins, and a system-specific nameplate based on the A6500/… is supplied with each Hot Half. The white-coated aluminum nameplate is individually printed with the system and customer-relevant data and covered with magnetic film. The two available sizes can be positioned either directly on the Hot Half or at a clearly visible point on the injection molding machine.

The Hot Half enables moldmakers and injection molders to considerably shorten design and production times for hot runner molds. Through its finely tuned assembly of the nozzles and its precise alignment of all the parts, the company ensures a leak-free system with functioning components.

The Hot Half is delivered within three to six weeks, depending on complexity. HASCO hot runner advisers and application technicians are available to assist customers worldwide and to configure an individual Hot Half in the optimum manner for the required application.

Mastip Inc. offers Nexus pre-assembled and pre-wired systems that incorporate FlowLoc nozzle technology. Mastip supplies Nexus Systems pre-assembled and pre-wired so that they are ready to be installed into a mold without the need of pre-heating. Nexus is suitable for automotive, appliance and electrical applications. Mastip says that FlowLoc nozzles on its Nexus pre-assembled system facilitate a thermal profile that enables a wide molding window without the risk of polymer leakage while offering protection from accidental cold-condition starting. Nexus Systems are able to process a wide range of commodity and aggressive, engineering-grade polymers, are suitable for high-pressure applications and are fully customizable to suit any specific requirements.

Mastip’s Nexus systems are compatible with FlowLoc 16, 19 and 27 series thermal-gate nozzles, which attach securely to the manifold with a threaded connection to provide a leak-proof solution. Mastip says that Nexus includes a customized wiring trunk to match specific mold layouts and offers quick removal of the complete unit from the mold for ease of service.

Thermal-Tech Systems will present the ProfiTemp+ hot runner control system at Amerimold. Hot runner control systems are a trending piece of technology that integrates the machine and hot runner and produces reliability with efficiency for a successful molding operation.

The ProfiTemp+ hot runner control system is easy to use and maintain and is network compatible. Additionally, it can be expanded, providing users with both flexibility and cost savings. Hot runner systems can be kept in balance with touch screen controls and data to alert users about areas that require attention. With today’s market, many companies are investing in technology and the end result is better quality parts and better performing hot runners, the company says.

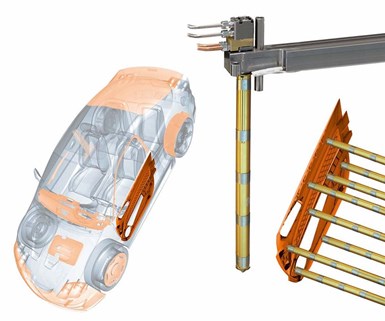

Incoe Corp. will introduce the Direct-Flo 12 nozzle with MultiPower MP24 heater, featuring reduced outer dimensions and simplified mold cut out, at Amerimold. According to the company, the nozzle provides a homogeneous temperature profile that produces optimum processing conditions. The MultiPower MP24 heater features two separate heating zones and lengths up to 600 mm, plus it has only a single cable outlet at the nozzle head, saving heating zones and lowering costs. Exchangeable thermocouples for both heating zones sit in matching grooves. An additional groove for each heating zone can incorporate a spare thermocouple. With the heater, the company has developed a consistent upgrade to its modular system, creating a compact valve gate solution. It can be used in tight spaces with gating points deep in the mold that need to be injected with plastic, such as the back injection of natural fiber mats for the manufacture of lightweight components for the automotive industry.

Plastixs LLC’s Airtect plastic leak detection system protects against plastic leak damage, either within a hot runner mold or at the machine injection nozzle. According to the company, it acts as an early warning device to prevent catastrophic damage in molding operations. This product enables users to identify solutions before a problem arises that is expensive to fix and causes significant downtime.