MMT Chats: 30 Under 30 Honoree, Mechanical Engineer Committed to Pushing 3D Printing Forward in Moldmaking

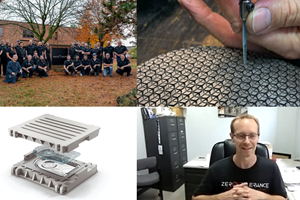

MoldMaking Technology Editorial Director Christina Fuges brings Action Mold & Machining’s Additive Specialist and CMM Technician Zachary Glascock as a guest for this MMT Chats video interview to discuss how he brought his passion for machining to moldmaking and the value of thinking outside the box to make better molds. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Share

This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

MoldMaking Technology’s 30 Under 30 Honors Program shows off the next-generation of talent making an impact across the mold manufacturing marketplace. Their stories are impressive and their energy is incredible! Working on this program has only increased my passion for this community!

Here are just a few tidbits from this 30 Under 30 honoree to whet your appetite for our full conversation:

- This mechanical engineer loves hands-on work.

- Co-op in tool and die watching and learning about the use of AM to produce conformal cooled inserts. Then using AM in venting applications in tools.

- Move past the traditional manufacturing mindset to open up new opportunities to make molds.

- Funny story about a mold Zack repaired using 3D printing and the colleague who took a hammer to it.

- AM and CMM together to verify his molds, engineering changes, etc.

- Looking forward to advancing how AM can be used in moldmaking. He is working with his manager to develop parameters.

- Learning, learning, learning.

- If you like to work with your hands, ask your teachers to expose you to opportunities to learn about and see manufacturing.

Related Content

-

Large Hybrid Steel Insert Solves Deformation, Dimensionality, Cycle Time Problems

DMLS printers using metal additive powders selected by Linear AMS to produce high-quality, accurate, consistent 3D-printed mold components with certification and traceability.

-

Precision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

-

How to Use Thermal Management to Improve Mold Cooling

A review of common mold cooling issues and possible solutions, including 3D printing applications.

Related Content

Large Hybrid Steel Insert Solves Deformation, Dimensionality, Cycle Time Problems

DMLS printers using metal additive powders selected by Linear AMS to produce high-quality, accurate, consistent 3D-printed mold components with certification and traceability.

Read MorePrecision Meets Innovation at IMTS 2024

After attending IMTS, it's clear that the integration of advanced technologies is ready to enhance precision, efficiency and automation in mold manufacturing processes. It’s a massive event, so here’s a glimpse of what the MMT team experienced firsthand.

Read MoreHow to Use Thermal Management to Improve Mold Cooling

A review of common mold cooling issues and possible solutions, including 3D printing applications.

Read More4 Keys to a Successful Mold-Building Operation, The Latest Mold Design Tips & More

MoldMaking Technology is off to a strong start this year with mold design tips, key considerations for running a mold-building “business,” polishing pointers for ribs and more. Check out our list of top-viewed articles from January and see what catches your eye.

Read MoreRead Next

MMT Chats: 30 Under 30 Honoree, Engineering Manager "Figuring It All Out"

MoldMaking Technology Editorial Director Christina Fuges brings on YakAttack Engineering Manager Nick Kellogg as a guest for this MMT Chats video interview to talk about the value of hands-on education, self-reliance, setting up systems and job satisfaction. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read MoreMMT Chats: The Connection Between Additive Manufacturing Education and ROI

This MMT Chat continues the conversation with Action Mold and Machining, as two members of the Additive Manufacturing team dig a little deeper into AM education, AM’s return on investment and the facility and equipment requirements to implement AM properly.

Read MoreMMT Chats: 30 Under 30 Honoree, Project Engineer & Lean Six Sigma Rep Shares Passion

MoldMaking Technology Editorial Director Christina Fuges brings on EDRO Specialty Steels Project Engineer Katherine Pistorius as a guest for this MMT Chats video interview to talk about her love of cutting waste, process management, and efficiency, which lead her to Lean Six Sigma. This episode is brought to you by ISCAR with New Ideas for Machining Intelligently.

Read More