Mold Materials

Advance Tool, Inc. (ATi): Thinking Lean Gets the Green

Boasting clients like Microsoft, Procter & Gamble and Nokia, ATi's customer-driven attitude takes them around the world - and earns them MoldMaking Technology magazine's Leadtime Leader Award.

Read MoreThe Role of Graphite in a Quality EDM Finish

While many moldmakers believe that they can get away with lower-grade graphite if they have a quality EDM machine, in reality, the quality of graphite plays a much larger role in achieving the right EDM finish.

Read MoreElectrical Discharge Generator Breaks New Ground

A brand new EDM generator achieves a cutting speed of 400 mm}/min, or 37 square inch/hour, for the first time in the world, and achieves the feat of marrying the integrity of the surfaces machined with a high cutting speed.

Read MoreOffline Programming for Competitive Solutions

New EDM technology can improve cycle time reduction and enhance cost savings.

Read MoreInland Technologies Bucks Trend

A unique mold shop ensures quality, on-time delivery using technology as its key tool.

Read MoreHow to EDM Large Surfaces Through Diesinking

A new technology allows moldmakers to control the EDM process and to ensure a uniform surface finish.

Read MoreKeys to Controlling Electrode Wear

By understanding exactly the causes behind electrode wear, moldmakers can learn how to reduce or even prevent wear - increasing the life of the electrodes.

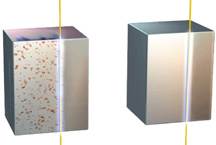

Read MoreLonger Electrode Life Benefits Moldmakers

New electrode-making process makes copper/tungsten electrodes last twice as long as graphite - with a better finish.

Read MoreIllinois Mold Shop Increases Productivity with Hole Driller

A high-speed CNC hole driller EDM machine allows Creative Die Mold to stay on the cutting edge.

Read MoreLaser Engraving Enhances Mold Design

Consideration should always be given to the optimum cost/quality relationship when choosing laser engraving.

Read More

.jpg;maxWidth=300;quality=90)