Wire EDM Module Streamlines Programming Process

HCL CAMWorks module offers a single-click model-to-G-code functionality, enhanced feature recognition for non-planar geometry, automatic angular wire threading and more.

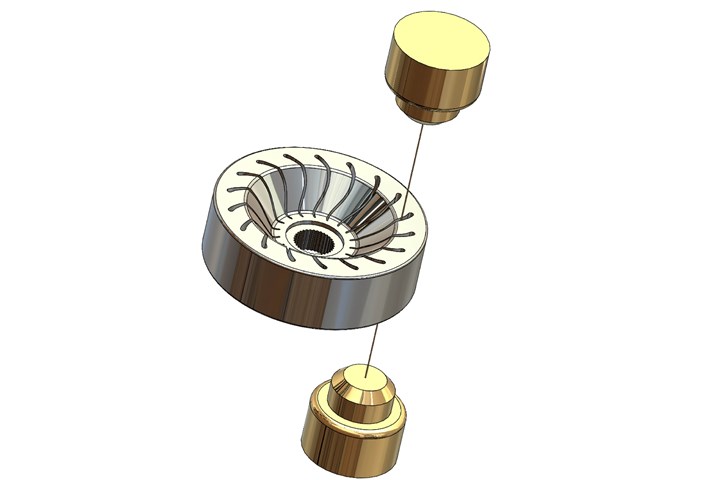

Photo Credit: HCL CAMWorks

HCL Technologies (HCL) announces a new wire EDM module for the CAMWorks suite of CAD/CAM software. The wire EDM module includes new functionalities that takes the design model to G-code in one click. Once the user clicks the “Solid to G-code” button, the system automatically searches the part for machine-able features, identifies them, generates all the operations with the users’ preferences and settings (including tool offsets, cutting conditions and start holes), creates the toolpaths and posts the G-code. Complex two-axis parts, two-axis parts with tapers and full four-axis wire EDM parts are programmable under this module.

Enhanced feature recognition for non-planar geometry is also offered. The wire EDM software uses geometry directly from the solid model to automatically construct and create the correct top and bottom profiles.

Additional highlights include automatic angular wire threading, support for SOLIDWORKS patterns and automation based on face colors. Automatic angular wire threading analyzes the part and automatically recognizes when angular threading would be required. It then creates the toolpaths necessary to enable angular threading of the wire and to machine the part. Support for SOLIDWORKS patterns is said to simplify the NC code and streamline the programming process by automatically identifying the patterns and utilizing them to simplify the CNC program. The technology based on face colors also enables easier identification and management of features to be programmed, as well as how they need to be machined. By assigning a color to the face of a part or to the entire part, user-defined machining strategies are assigned automatically.

Related Content

-

Three Good Reasons to Switch from Three- to Five-Axis Machining in Moldmaking

Five-axis machining technology is a great tool in the moldmaker toolbox.

-

Tolerancing in Mold Design, Part 1: Understanding the Issues of Conventional Bilateral Tolerancing

Mold designers must understand the location, orientation and form limitations of conventional tolerancing before changing to another dimensioning system.

-

Mold Design Review: The Complete Checklist

Gerardo (Jerry) Miranda III, former global tooling manager for Oakley sunglasses, reshares his complete mold design checklist, an essential part of the product time and cost-to-market process.