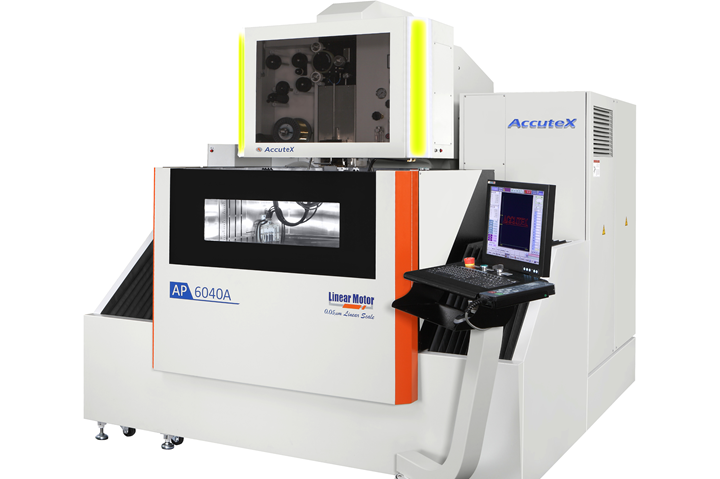

Wire-Cut EDM Facilitates Highly Rigid Large Mold Component Machining

Absolute Machine Tools offers the AP Series, including the Accutex AP-6040A, with a rigid structure, high cutting accuracy and improved maximum loading weight.

Photo Credit: Absolute Machine Tools Inc.

Absolute Machine Tools offers the AP Series wire-cut EDM machines, including the Accutex AP-6040A, for large mold component machining. These systems reportedly offer a highly rigid structure, Windows CE controller, new generation shaft-type linear motor, an ultra-resolution signal processor, cutting efficiency comparison, a corner control function, high cutting accuracy and new lead-in/lead-out control. Optional features include a CIMFORCE Industry 4.0-intelligent integration system, auto-wire threading and 0.05-0.1-mm fine wire application.

According to the company, the AP series machine structure was designed via finite element analysis (FEA) and offers an improved maximum loading weight up to 1,000 kg. The bi-repeatability is said to be less than 2.5μm after five times laser calibration. The AccuteX controller is based on Window CE system and features precise motion control with rapid servo response that can reportedly improve cutting efficiency up to 10%. A linear scale interpolation board with ultra resolution can achieve smooth velocity and stabilized position control. The systems have simplified generator and electric circuits to eliminate unnecessary power loss. An onboard Marposs probe function enables fast alignment, location of key blind features and post-machining measurement.

Related Content

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

-

Advantages and Disadvantages of Copper and Graphite Electrodes

Both copper and graphite provide approximately the same end result, so it is important for a shop to consider the advantages and disadvantages of each material in order to discover what would work best in their shop floor environment.

-

The Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

.jpg;maxWidth=300;quality=90)